T8602C CHRONOTHERM® IV DELUXE PROGRAMMABLE THERMOSTATS

WIRING

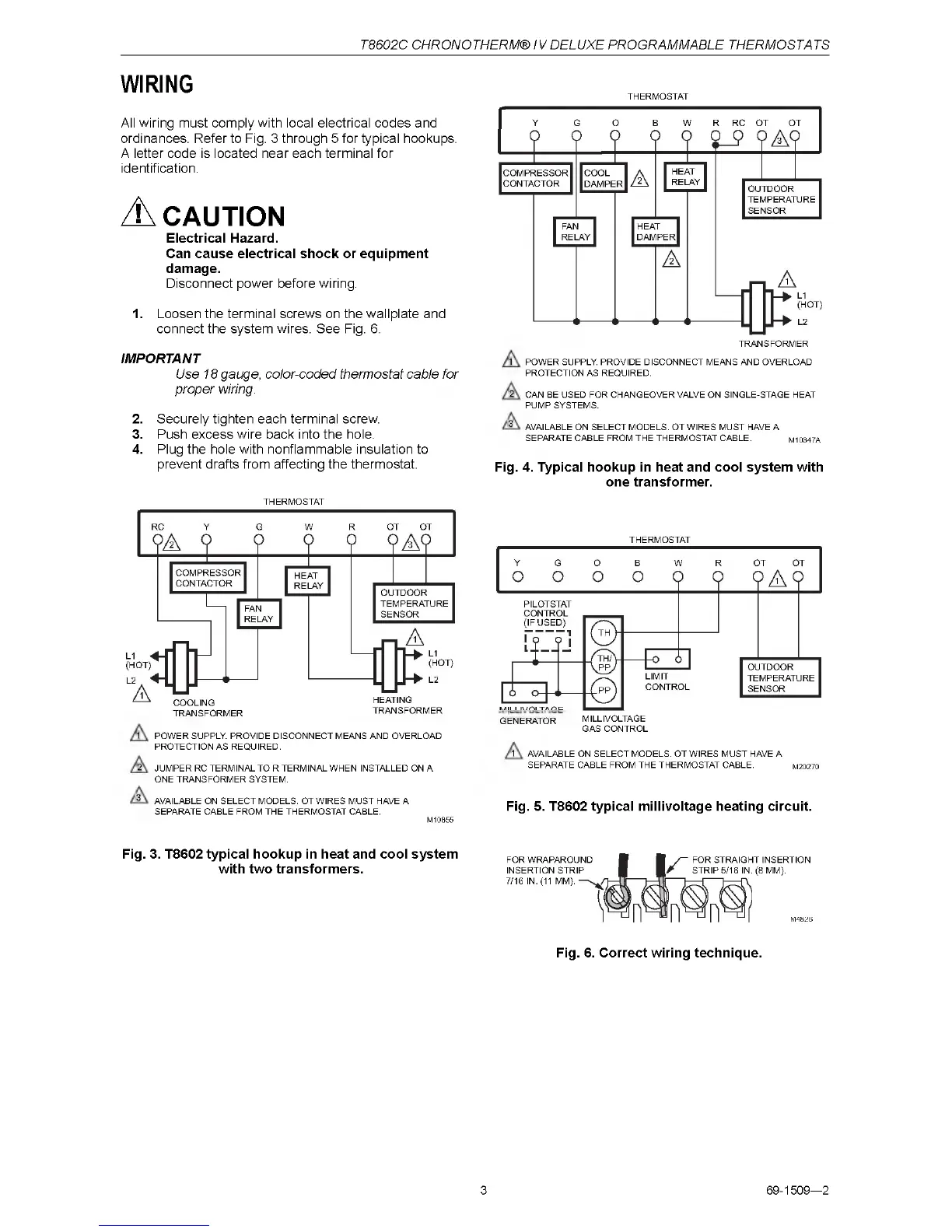

THERMOSTAT

All wiring must comply with local electrical codes and

ordinances. Refer to Fig. 3 through 5 for typical hookups.

A letter code is located near each terminal for

identification.

A CAUTION

Electrical Hazard.

Can cause electrical shock or equipment

damage.

Disconnect power before wiring.

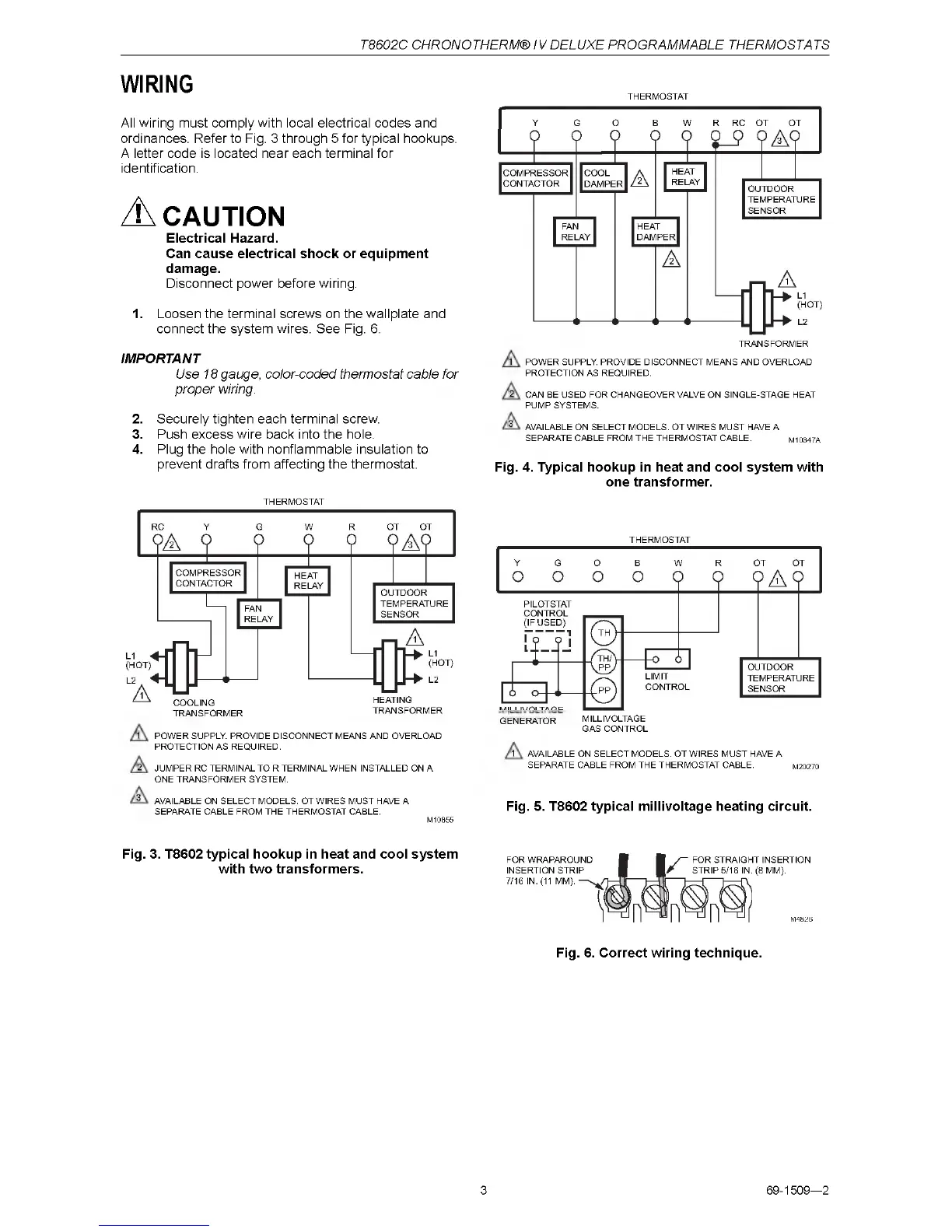

1. Loosen the terminal screws on the wallplate and

connect the system wires. See Fig. 6.

IMPORTANT

Use 18 gauge, color-coded thermostat cable for

proper wiring.

2. Securely tighten each terminal screw.

3. Push excess wire back into the hole.

4. Plug the hole with nonflammable insulation to

prevent drafts from affecting the thermostat.

Y G O B W R RC OT OT

TRANSFORMER

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2 CAN BE USED FOR CHANGEOVER VALVE ON SINGLE-STAGE HEAT

PUMP SYSTEMS.

3 AVAILABLE ON SELECT MODELS. OT WIRES MUST HAVE A

SEPARATE CABLE FROM THE THERMOSTAT CABLE. M10347A

Fig. 4. Typical hookup in heat and cool system with

one transformer.

THERMOSTAT

1 POWER SUPPLY. PROVIDE DISCONNECT MEANS AND OVERLOAD

PROTECTION AS REQUIRED.

2 JUMPER RC TERMINAL TO R TERMINAL WHEN INSTALLED ON A

ONE TRANSFORMER SYSTEM.

3 AVAILABLE ON SELECT MODELS. OT WIRES MUST HAVE A

SEPARATE CABLE FROM THE THERMOSTAT CABLE.

M10855

THERMOSTAT

GENERATOR M1ILLIV°LTAGE

GAS CONTROL

1 AVAILABLE ON SELECT MODELS. OT WIRES MUST HAVE A

SEPARATE CABLE FROM THE THERMOSTAT CABLE. M20270

Fig. 5. T8602 typical millivoltage heating circuit.

Fig. 3. T8602 typical hookup in heat and cool system

with two transformers.

FOR WRAPAROUND

INSERTION STRIP

7/16 IN. (11 MM).

FOR STRAIGHT INSERTION

STRIP 5/16 IN. (8 MM).

M4826

Fig. 6. Correct wiring technique.

3 69-1509—2

Loading...

Loading...