9 60-2307—10

V5055A-E

OPERATION AND CHECKOUT • SERVICE INFORMATION

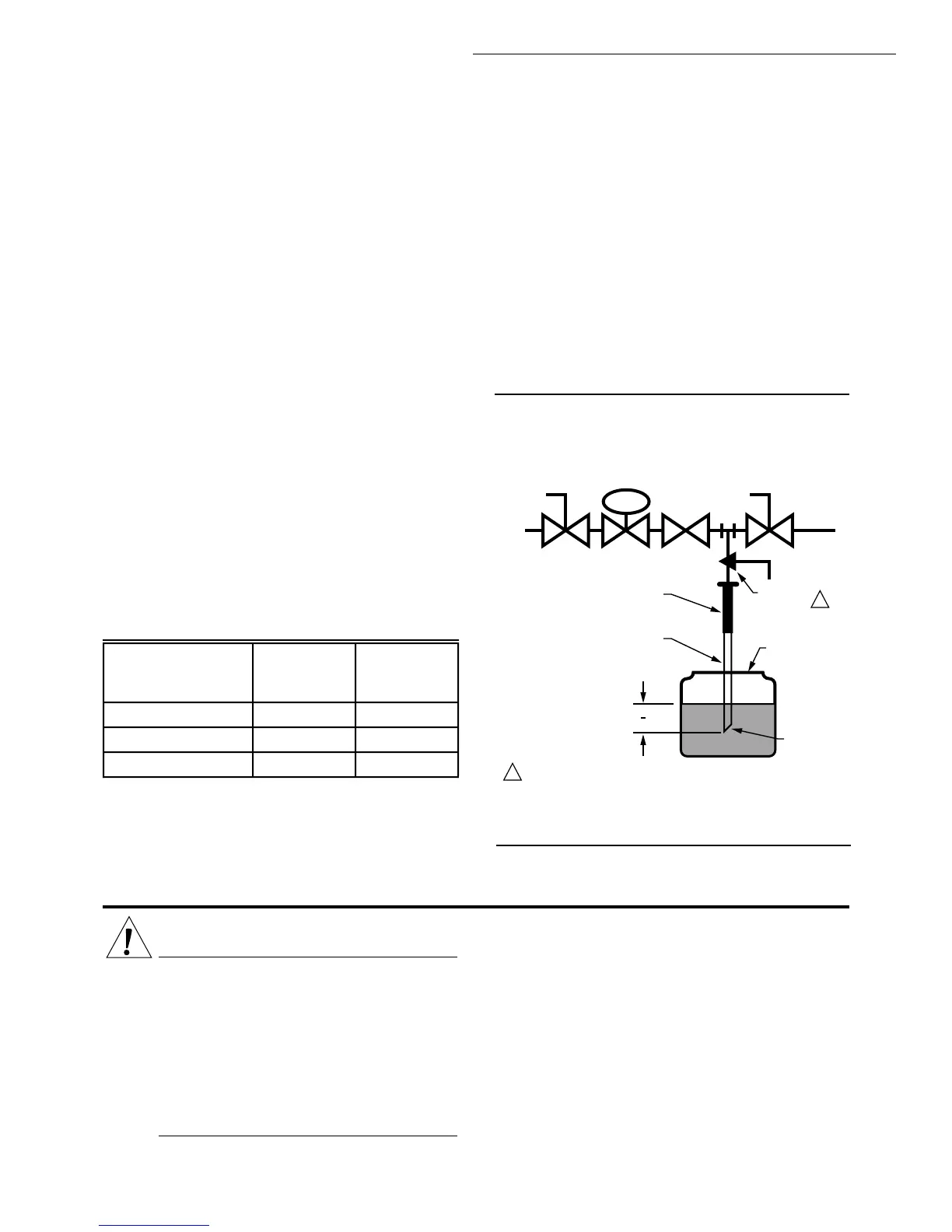

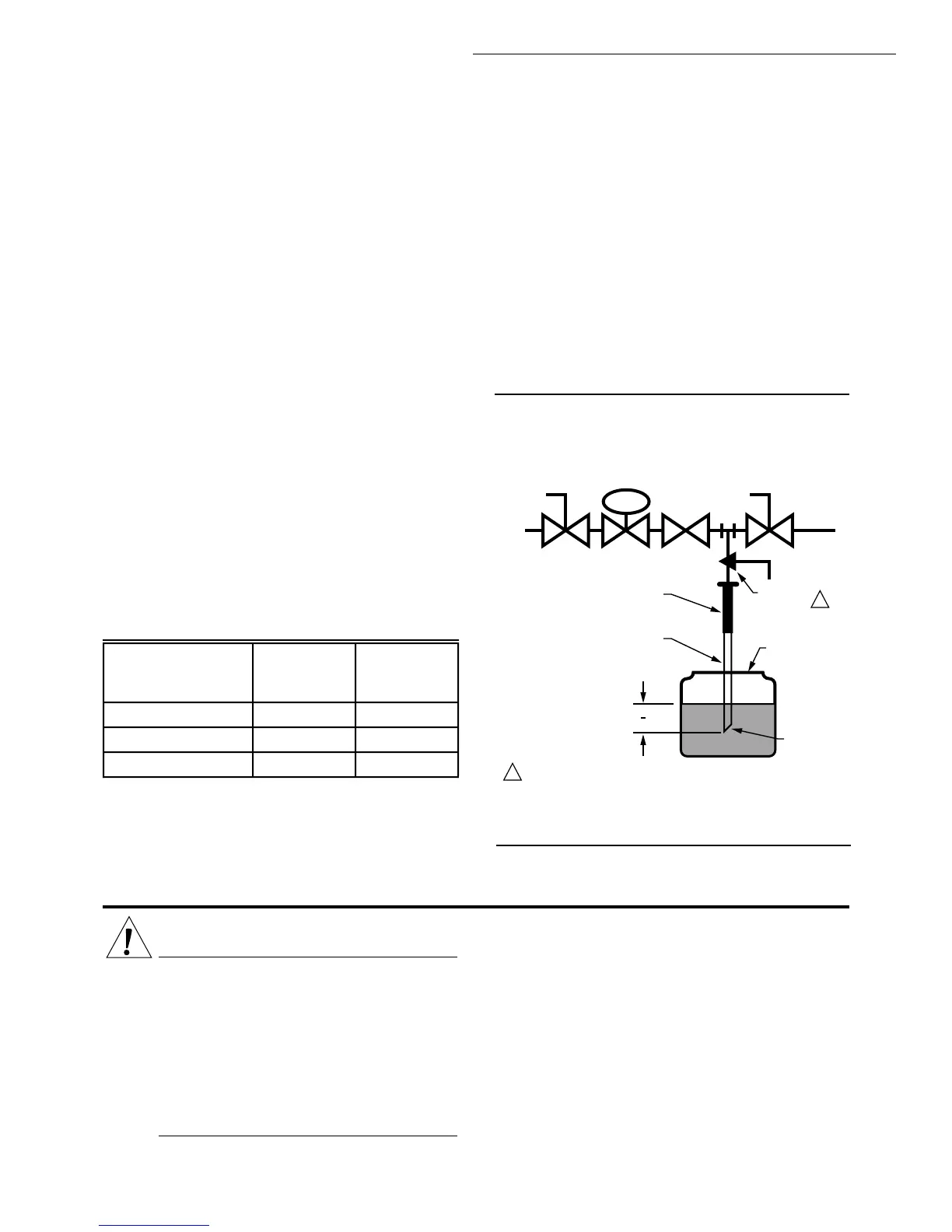

VALVE LEAK TEST (Fig. 7)

This is a test for checking the closure tightness of a gas

safety shutoff valve. It should be performed by qualified

personnel during the initial startup of a burner system, or

whenever the valve or valve bonnet is replaced (see Service

Information section). It is recommended that this test also

be included in the scheduled inspection and maintenance

procedures. For a periodic inspection test, follow steps 1,

3, 4, 5, 8, 9, 10, 12, 13, 16, and 17.

1. De-energize the control system to assure that there is

no power to the safety shutoff valve (C) shown in Fig. 7.

2. Close the upstream manual gas cock (A).

3. Make sure the manual test petcock (F) is closed in the

leak test tap assembly (D).

4. Remove the leak test tap plug and connect the test

apparatus to the Leak Tap (D).

5. Close the downstream manual gas cock (E).

6. Open the upstream manual gas cock (A).

7. Run the safety shutoff valve (C) to its fully open

position (through the safety system); then immediately de-

energize the system to close the valve.

8. Immerse a 1/4 in. tube vertically 1/2 in. (12.7 mm) into

a jar of water.

9. Slowly open the test petcock (F).

10. When the rate of bubbles coming through the water

stabilizes, count the number of bubbles appearing during a

ten-second period. Each bubble appearing during a ten-

second period represents a flow rate of approximately

0.001 cfh.

To meet U.S. requirements, leakage must not exceed the

following values:

V5055

Pipe Size

(in.)

Allowable

Leakage

(cc/hr)

a

Number of

bubbles per

10 sec

3/4, 1, 1-1/4, 1-1/2 458 16

2, 2-1/2, 3 752 26

4 1003 35

a

Based on air at standard conditions, test pressures pro-

vided by ANSI Z21.21, Section 2.4.2 and a maximum of

235 cc/hr per inch of seal-off diameter. Seal-off diameter

is not to be confused with pipe size.

NOTE: For international leak test requirements, contact the

office of the appropriate approval agency.

AFTER THE TEST:

11. Close the upstream manual gas cock (A).

12. Close the test petcock (F), remove the test apparatus,

and replace the leak test tap plug (D).

13. Open the upstream manual gas cock (A) and energize

the safety shutoff valve (C).

14. Test with soap bubbles to assure that there is no leak at

the test tap (D).

15. De-energize the safety shutoff valve (C).

16. Open the downstream manual gas cock (E).

17. Restore the system to normal operation. If two safety

shutoff valves are utilized, each 550V valve is to be checked

for tightness of closure.

Fig. 7—Valve Leak Test.

M9547

GAS

SUPPLY

MANUAL

GAS COCK

MANUAL

GAS COCK

BURNER

D

LEAK

TEST

TAP

ABC E

F

PRV

TEST

PETCOCK

SSOV

1/4 in. FLEXIBLE

TUBING

1/4 in. ALUMINUM

OR COPPER PILOT

TUBING

JAR OR GLASS

WITH WATER

CUT AT

45 DEGREE

ANGLE

MAY ALSO BE A PERMANENT PETCOCK.1

1

1

2

[12.7]

Service Information

SCHEDULED INSPECTION AND MAINTENANCE

Setup and follow a schedule for periodic inspection and

maintenance, including the burner, all other controls, and

the valve(s). It is recommended that the Valve Leak Test in

the Checkout section be included in this schedule. Refer to

the Instructions for the primary safety control for more

information.

VALVE BONNET REPLACEMENT

The entire valve bonnet may be replaced without re-

moving the valve body from the gas line. Do not disas-

semble the valve bonnet assembly; the valve seat is not

replaceable.

CAUTION

1. Before servicing, turn off the gas supply and dis-

connect all electrical power to the valve actuator.

2. Only qualified service technicians should at-

tempt to service or repair flame safeguard con-

trols and burner systems.

3. Do not disassemble the valve bonnet assembly;

the valve seat is not replaceable.

4. Failure to properly position and seat the seals in

the valve body may result in a hazardous gas

leak.

Loading...

Loading...