EN

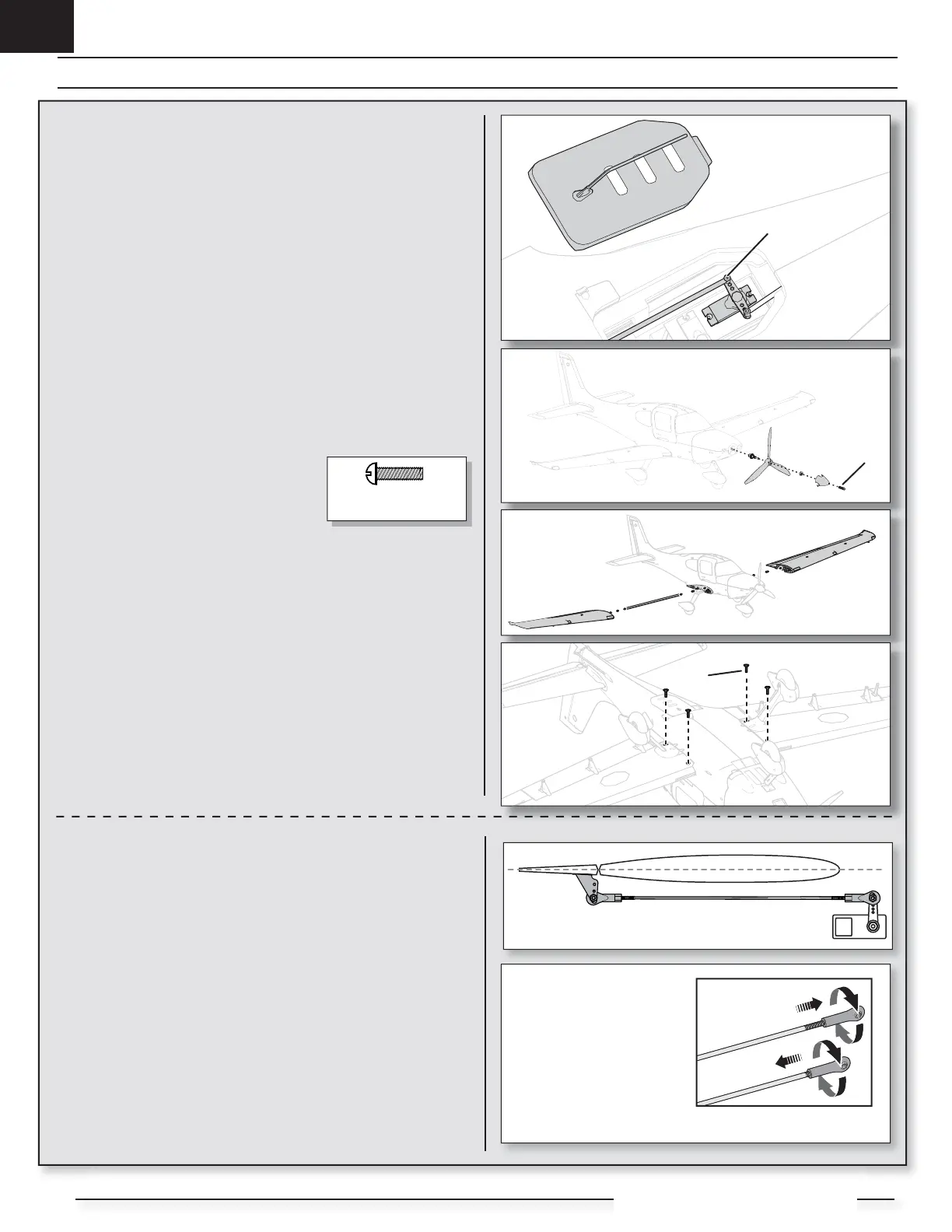

Model Assembly Continued

3 x 8mm

button head machine

B,C

B

A

C

Wing Installation

IMPORTANT: The integrated servo connectors are in the wing and fuselage.

Ensure that they slide together correctly.

1. Secure the wing halves into position using the included 3 x 8mm screws (C).

Disassemble in reverse order.

Propeller Installation

1. Install the Prop adapter, propeller, prop washer and nut.

2. Tighten the nut until the prop adaptor grasps the propeller shaft securely.

3. Secure the spinner with a 3 x 8mmv screw (B).

Disassemble in reverse order.

Nose Gear Centering

Factory settings for the nose gear steering trim should be close; observe the

following steps to fi ne tune the nose gear trim.

1. With the radio control system powered on, the rudder centered, and the rudder

trim centered, check the nose gear trim is centered.

2. To make adjustments, remove the servo hatch on the bottom of the fuselage.

The hatch is held with two magnets in the front and a tab in the rear.

3. Fine-tune the nose gear trim at the rudder servo by loosening the set screw

on the adjustable servo to pushrod linkage (A) and sliding the pushrod to the

desired position.

4. Tighten the screw to lock the pushrod into position.

5. Re-install the servo hatch.

8

Cirrus SR22T

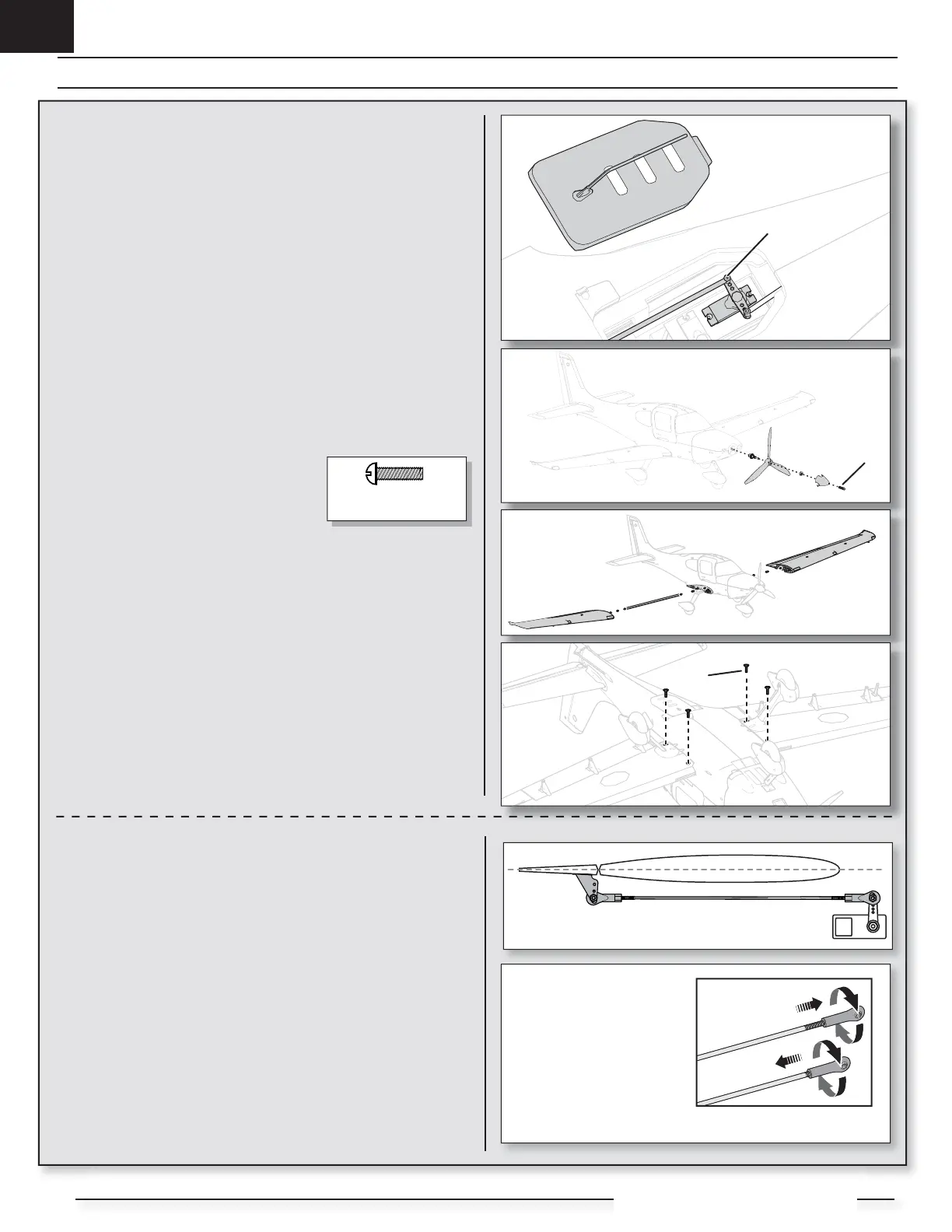

Control Surface Centering

After assembly and transmitter setup, confi rm that the control surfaces are

centered. If the control surfaces are not centered, mechanically center the control

surfaces by adjusting the linkages.

If adjustment is required, turn the ball link on the linkage to change the length of

the linkage between the servo arm and the control horn.

After binding a transmitter to the aircraft receiver, set the trims and sub-trims to

0, then adjust the ball links to center the control surfaces.

• Turn the linkage

clockwise or

counterclockwise until

the control surface is

centered.

• Attach the linkage

to the servo arm or

control horn after

adjustment.

Loading...

Loading...