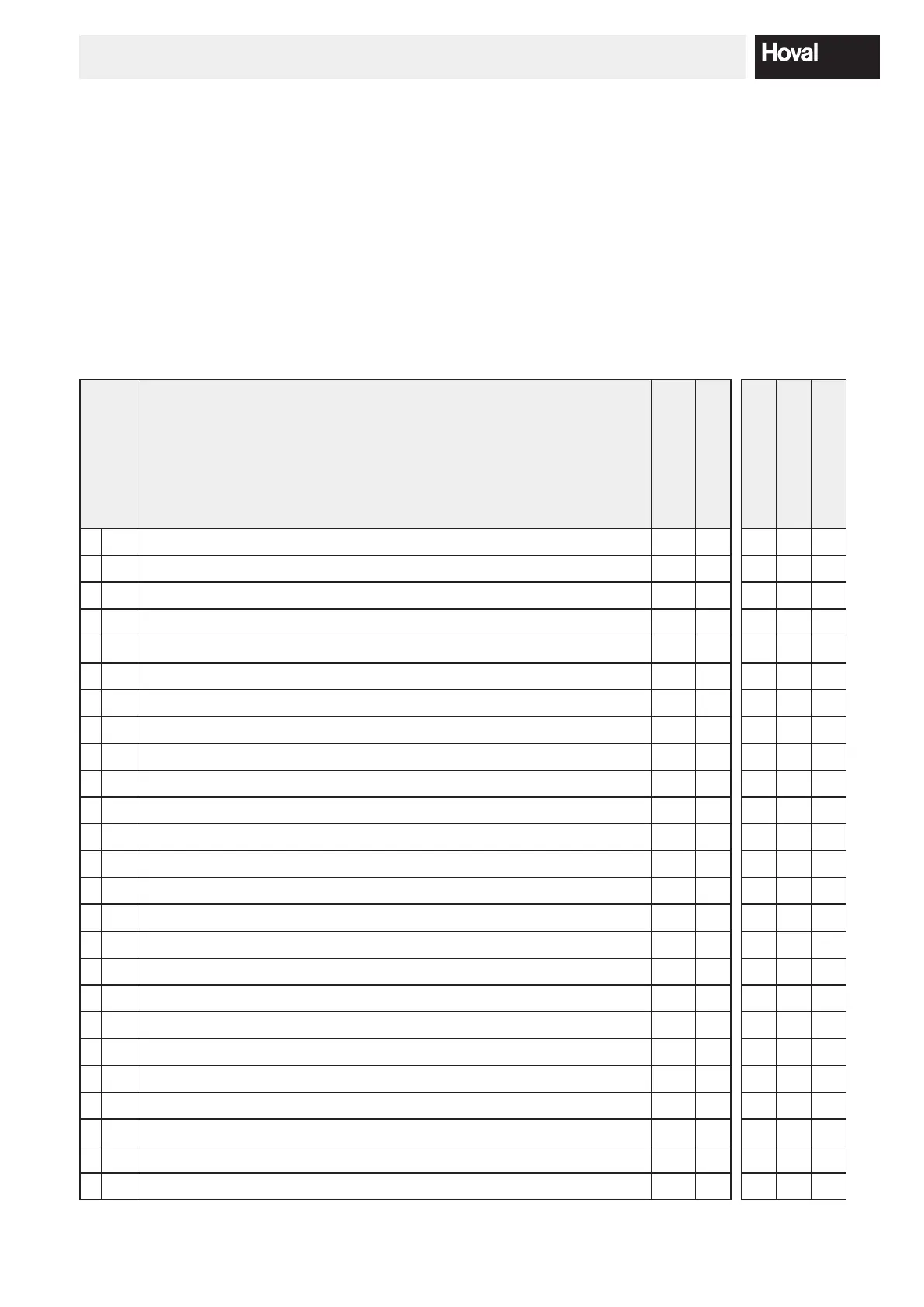

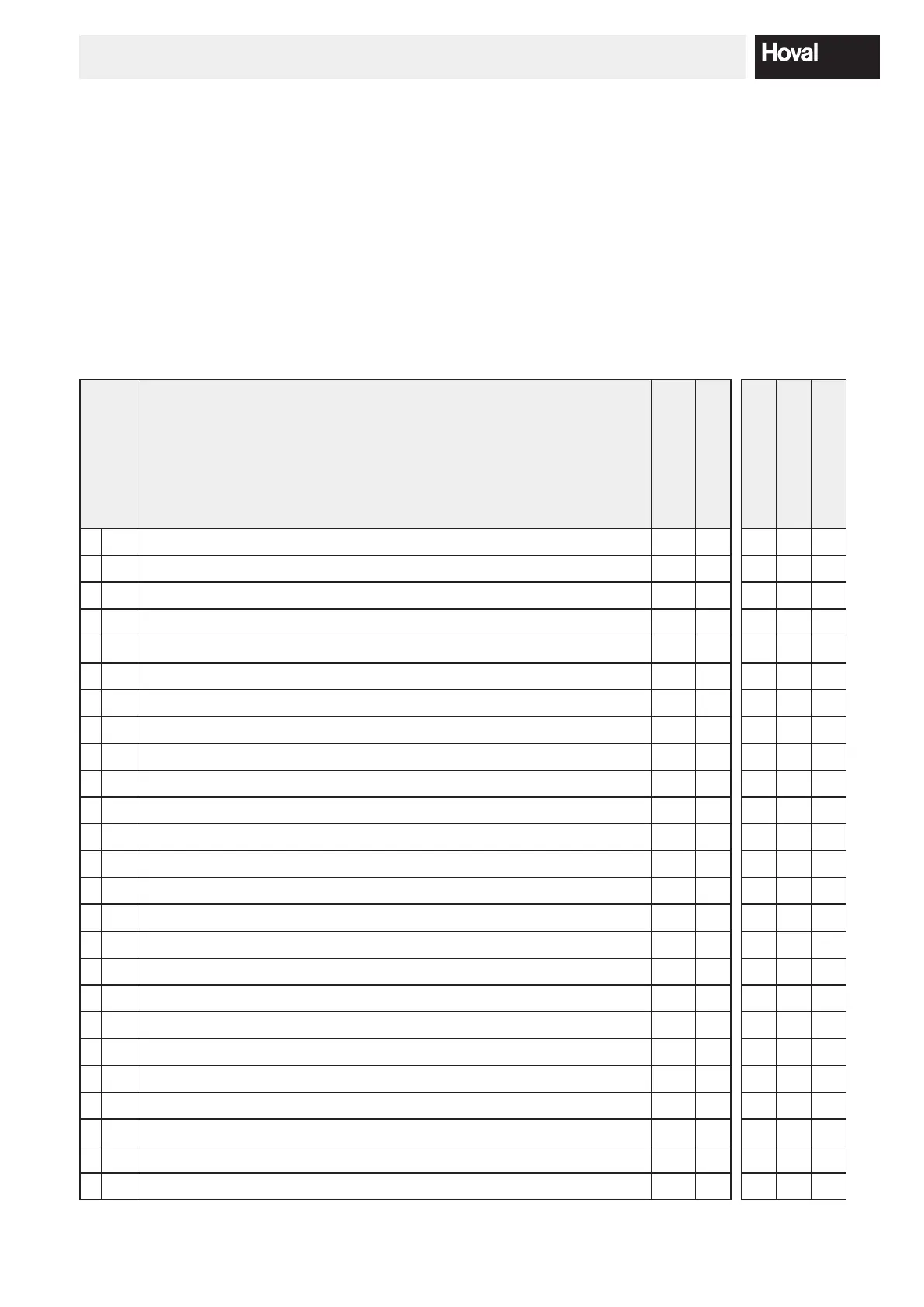

394 205 503 / 14

PARAMETER LISTS

Parameter

Description

Unit

Level

Factory setting

1-CompactGas

®

(240)

1-CompactGas

®

(200)

1-CompactGas

®

(280)

1 2AA Blocking temperature °C OEM 100 100 100

2 2AC Maximum reference value °C BE 85 85 85

3 2AD Switch-off hysteresis above reference value °C OEM 10

4 2AE Switch-on difference relating to tripping point °C HF 10

5 2AF Proportional part °C OEM 20 20 20

6 2AG Integral part sec OEM 100 100 100

7 2AH Differential part sec OEM 0 0 0

8 2AI Reference value when bus interruption °C HF 75

9 2AJ Max. temperature rise at low ow temperature °C/sec OEM 2 2 2

10 2AK Max. temperature rise at high ow temperature °C/sec OEM 1 1 1

11 2AL “Low” ow temperature °C OEM 60

12 2AM “High” ow temperature °C OEM 80

13 2BC Lock-out ue gas temperature °C OEM 110

14 2BD Blocking ue gas temperature °C OEM 100

15 2CA Gas pressure switch attached OEM

ON

16 2DA Water pressure sensor attached OEM

ON

17 2DB Water pressure warning bar OEM 1

18 2DC Water pressure hysteresis bar OEM 0.2

19 2DD Blocking pressure min. bar OEM 0.5

20 2DE Blocking pressure min – hysteresis bar OEM 0.2

21 2DF Blocking pressure max bar OEM 4.8

22 2DG Blocking pressure max – hysteresis bar OEM 0.2

23 2DH Lock-out pressure max bar OEM 5

24 2DI Max. boiler performance at pressure warning % OEM 50

25 2EC Ionisation warning µA OEM 3

13.11 1 - CompactGas

®

(200-280)

Attention:

The automatic gas ring device BIC 960 which must be used for the CompactGas

®

boiler does not correspond with the

BIC 960 used with the UltraGas

®

boiler.

Therefore when exchanging an automatic gas ring device on a CompactGas

®

, an article No. 6017 963 must be

installed in the ordered BIC 960.

Otherwise the locking fault E:02 would be displayed which cannot be acknowledged because no ue gas sensor is

installed in the CompactGas

®

.

Blocking temperature to max. 100°C on request.

Loading...

Loading...