35

Motor

Manual

are equipped as standard with lifetime greased bearings in

frames size up to 225. Motor types MS and Y2E are equipped

as standard with lifetime greased bearings in frame sizes

up to 160. Typical operating hours for lifetime lubricated

bearings are shown in Table 14, Lubricated bearing lifetime.

It is important that the shaft seals are intact.

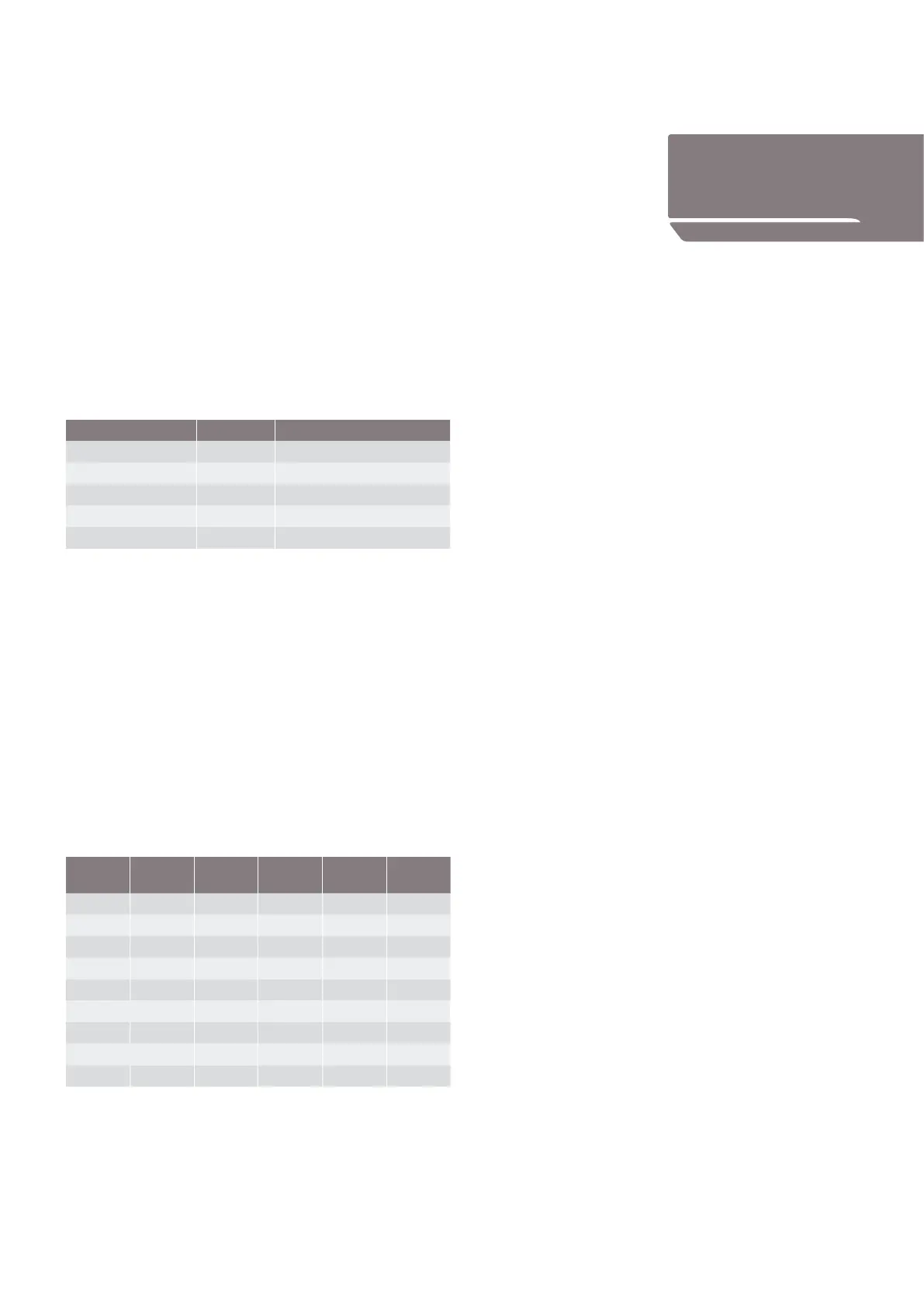

Frame size Poles Typical lifetime

50–160 2–8 40,000 h

180 2 35,000 h

200 2 27,000 h

225 2 23,000 h

180–225 4–8 40,000 h

Table 17 Lubricated bearing lifetime

Motors with re-greaseable bearings are equipped with a

greasing data plate. If the data plate is missing, or the infor-

mation on it unreadable, please use the re-greasing intervals

shown in Table 15, Re-greasing intervals and amounts.

Values on Table 15 are calculated based on worst case sce-

narios so it fits on a wider application range, whereas values

on the nameplates are calculated for the respective motor

specification. As a result, the data on the motor greasing

plate can deviate from the values on Table 15. Different mo-

tor items, with the same bearing size and type may also have

different re-greasing periods for the same reason. For miss-

ing greasing data plate or any doubt please contact Hoyer.

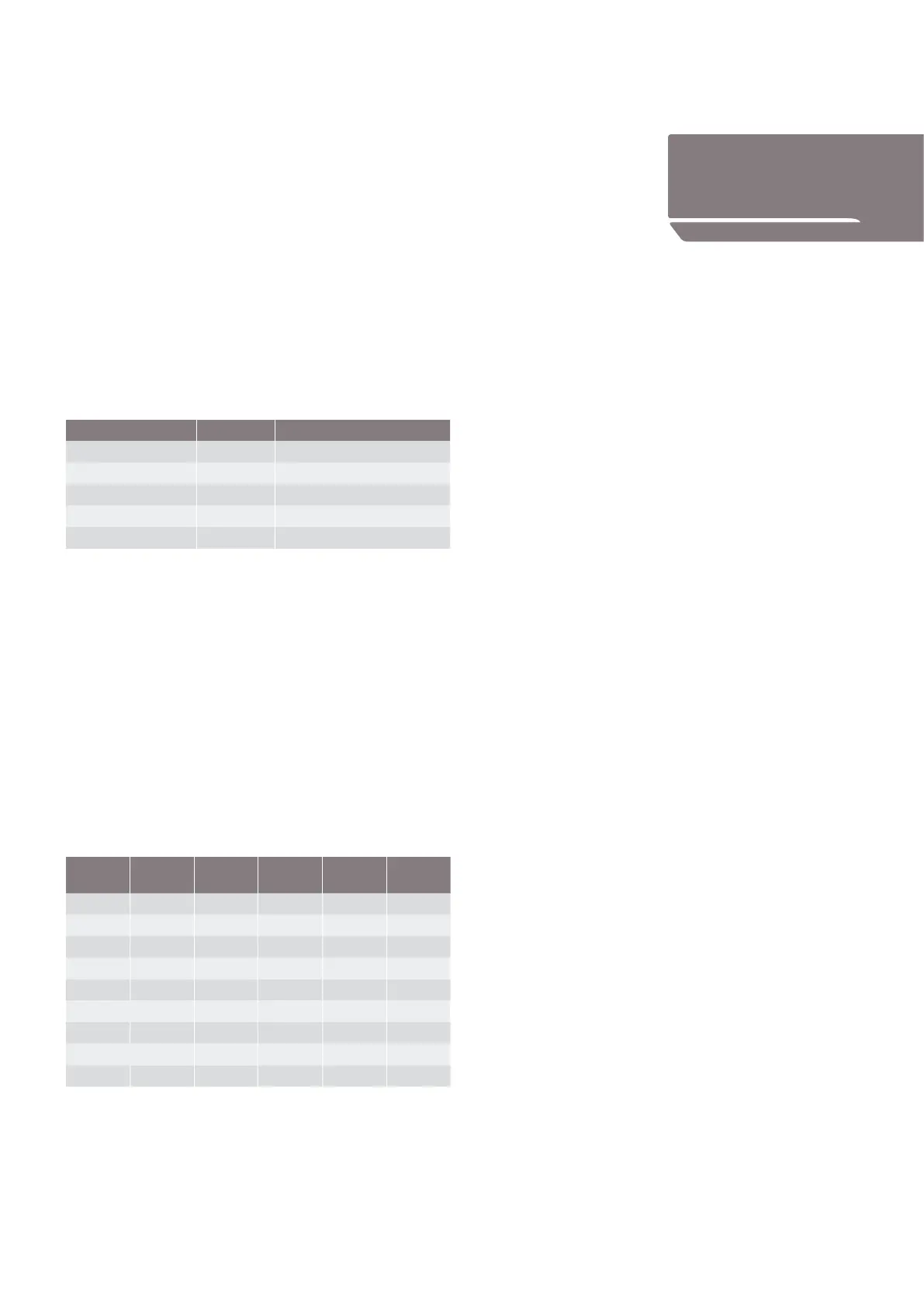

Frame

size

Grease

(g)

2-pole

(h)

4-pole

(h)

6-pole

(h)

8-pole

(h)

160 20 4200 7000 8500 8500

180 20 4200 7000 8500 8500

200 25 3100 6500 8500 8500

225 25 3100 6500 8500 8500

250 35 2000 6000 7000 7000

280 35 2000 6000 7000 7000

315 50 1500 5500 6500 6500

355 60 1000 4000 5000 6000

400 80 800 3000 4000 6000

Table 18 Re-greasing intervals and amounts

A suggestion for re-greasing procedure can be as follows:

1. Remove the fan cover (If grease inlet and outlet is not

accessible through the fan cover in NDE).

2. Open the dust protection cap of the grease nipple inlet

and the grease outlet both for DE and NDE.

3. Check if the grease nipple is clean and free of dirt.

4. Remount the fan cover (If grease inlet and outlet is not

accessible through the fan cover in NDE).

5. Run the motor till it has reached its hot condition nor-

mally 1-2 hours (skip this point for the first startup).

6. Use manual or automatic grease gun and add the speci-

fied grease type and amount while the motor is run-

ning (N.B. the fan cover must always be fixed on the

motor when its running).

7. Take of the grease gun and let the motor run in order to

get the old grease out approx. 1-2 hours.

8. Stop the motor and wait for complete standstill.

9. Dismount the fan cover If grease inlet and outlet is not

accessible through the fan cover in NDE).

10. Close the dust protection cap of the grease nipple inlet

and the grease outlet.

11. Clean up the old grease.

12. Remount the fan cover (If grease inlet and outlet is not

accessible through the fan cover in NDE).

Note: Due to danger it is forbidden to get in contact with

rotating or live parts under the maintanance. At the first

startup for the motor the bearings must be greased before

startup, else the bearings will be damaged.

Loading...

Loading...