5

Motor

Manual

3 Receipt, transport and storage

3.1 Receipt and transport

Upon receipt and for transport:

• Use transport locks for all transport operations.

• Avoid moisture and shocks during transport.

• Check the motor for external damage.

• If damage is found, inform the sales representative of

Hoyer Motors.

• Check all nameplate data and compare it with the re-

quirements for the motor.

• Remove transport locks if present.

• Turn the shaft by hand to check for free rotation.

3.2 Storage

• Ensure the use of correct lifting lugs. Lifting lugs are

dimensioned for the weight of the motor.

• Do not apply extra weight.

• If necessary, use suitable special equipment such as

lifting gear and ropes.

• Store in a dry, dust-free and vibration-free location.

• Carefully consider long-term storage procedures.

Short-term storage (less than 2 months)

The motor should be stored in a place with a controllable

environment. A good warehouse or storage location has:

• Measure the insulation resistance and temperature

of the windings to check whether the motor has been

stored improperly, even for a short time.

• A stable temperature, preferably in the range from 10°C

(50°F) to 50°C (120°F). If the anti-condensation heaters

are energised and the surrounding air is above 50°C

(120°F), ensure that the motor is not overheated.

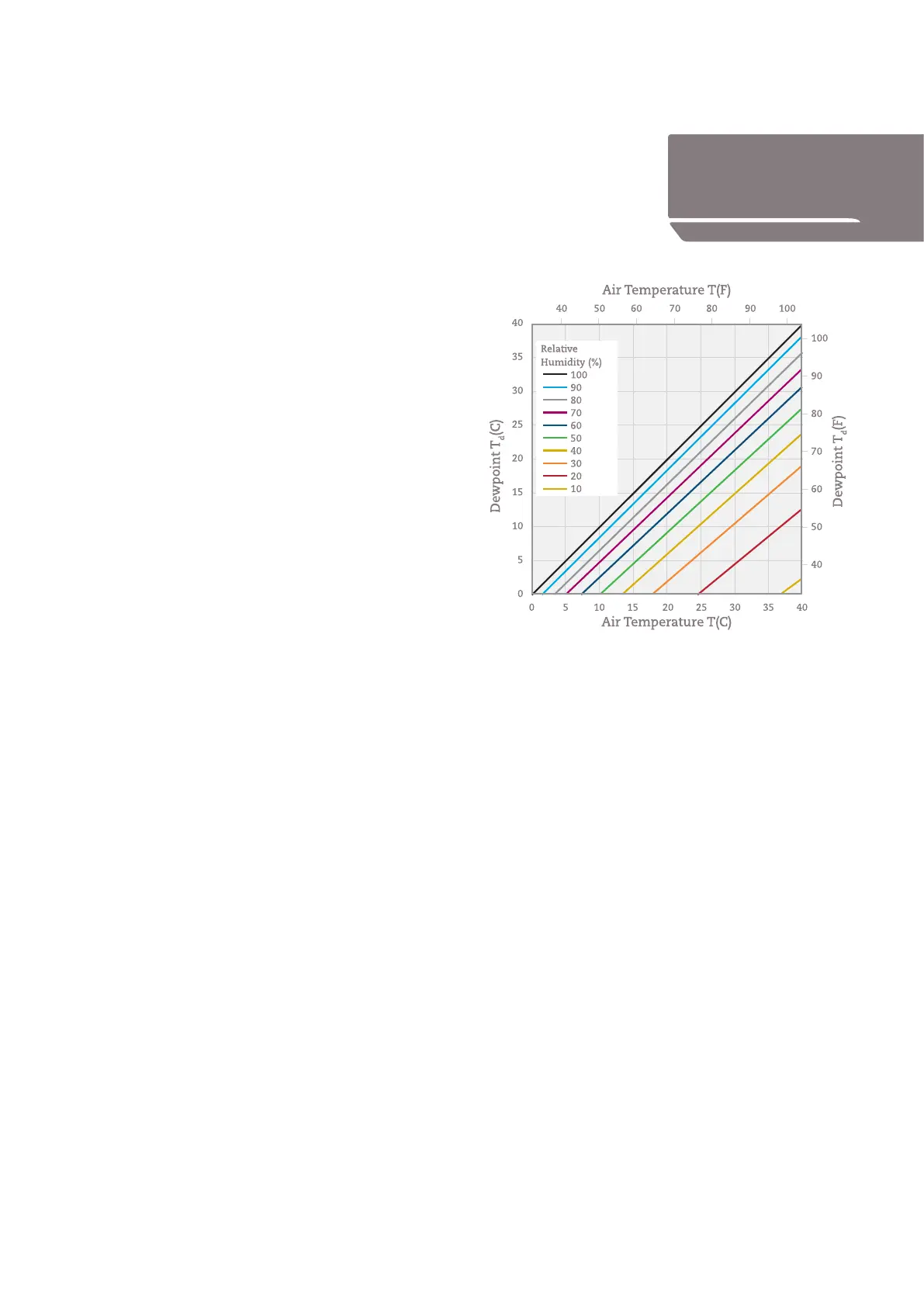

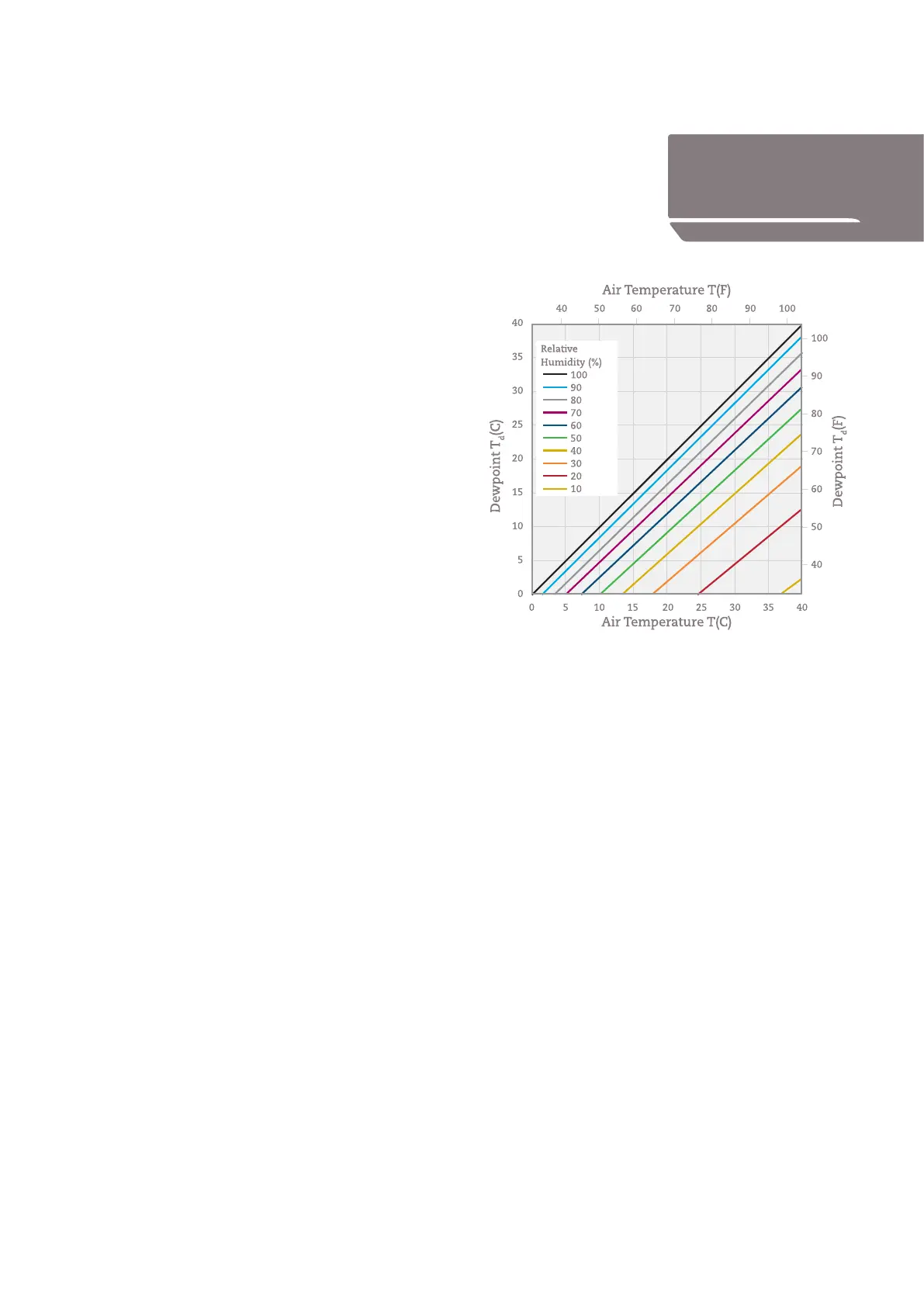

• Low air humidity, preferably below 75%. The motor

temperature must be kept above the dew point shown

in the figure to prevent water vapour from condensing

inside the motor. If the motor is equipped with anti-

condensation heaters, they should be energised. Proper

operation of the anti-condensation heaters must be

checked periodically. If the motor is not equipped with

anti-condensation heaters, other methods of heating

the motor must be used to prevent water vapour from

condensing in the motor.

• A stable support free from excessive vibration and

shocks. If vibration levels are expected to be too large,

the motor should be isolated by placing suitable rubber

blocks under the motor feet.

• Air that is ventilated, clean and free from dust and cor-

rosive gases.

• Protection against harmful insects, vermin and chemi-

cals.

Long-term storage (more than 2 months)

In addition to the measures described for short-term stor-

age, the following actions are necessary:

• Measure the insulation resistance and temperature

of the windings to check whether the motor has been

stored improperly, even for a short time.

• Check the condition of the paintwork every three

months. If corrosion is seen, remove it and apply a new

coat of paint.

• Check the condition of the anti-corrosion coating on

bare metal surfaces every three months. If corrosion is

seen, remove it gently with emery cloth and apply an

anti-corrosion coating.

• Provide small ventilation openings if the motor is

stored in a wooden crate. Prevent water, dust and in-

sects from entering the crate.

Loading...

Loading...