ENWW Image defects 385

Poor fusing

Image distortion

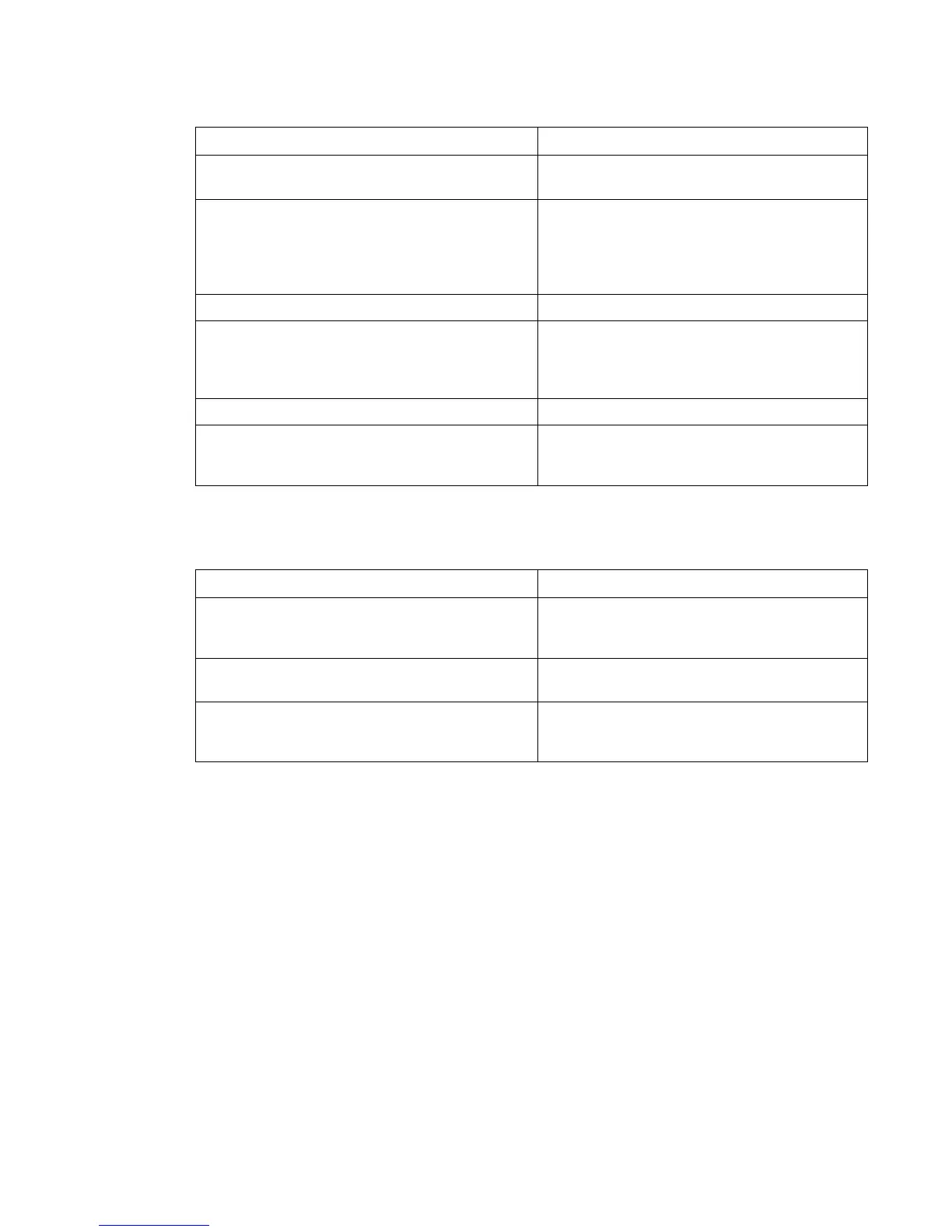

Table 7-32 Causes for poor fusing

Cause Solution

Media is not within specifications. For example, media

that is too thick causes poor fusing.

Use media that meets specifications. See F, in

chapter 1.

Fuser is not within nip width specifications. Refer to the Repetitive defect cause table, later in

this chapter,

to find out if the interval of the

poorly fixed

places agrees with that of a fuser

sleeve. If so, replace the fuser sleeve unit. Replace

the fuser.

Fuser sleeve is scarred or damaged. Replace the fuser.

Pressure roller is scarred or damaged. Refer to the Repetitive defect cause table, later in

this chapter, to find out if the interval of the poorly

fixed places agrees with that of a pressure roller. If

so, replace the fuser.

Thermistor is deteriorated. Replace the fuser.

DC controller PCB is defective. Replace the DC controller PCB. Calibrate the printer

after replacing the DC controller. See Calibrate Now,

later in this chapter.

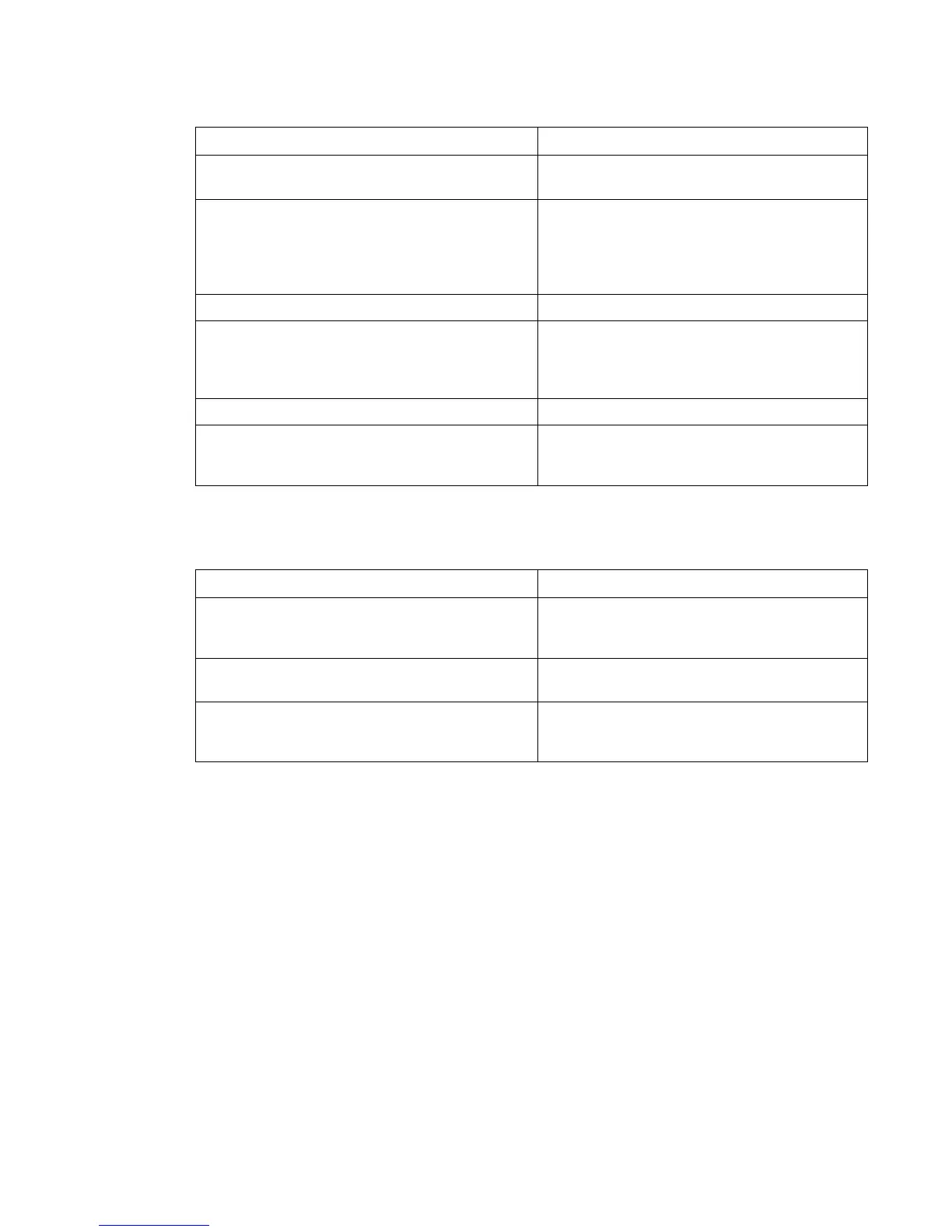

Table 7-33 Causes for distortion or blurring

Cause Solution

Transfer unit is defective. Replace the transfer unit. Calibrate the printer after

replacing the transfer unit. See Calibrate Now, later

in this chapter.

Defective secondary transfer roller If it does not rotate smoothly or it is deformed,

replace the secondary transfer roller.

DC controller PCB is defective. Replace the DC controller PCB. Calibrate the printer

after replacing the DC controller. See Calibrate Now,

later in this chapter.

Loading...

Loading...