386 Troubleshooting ENWW

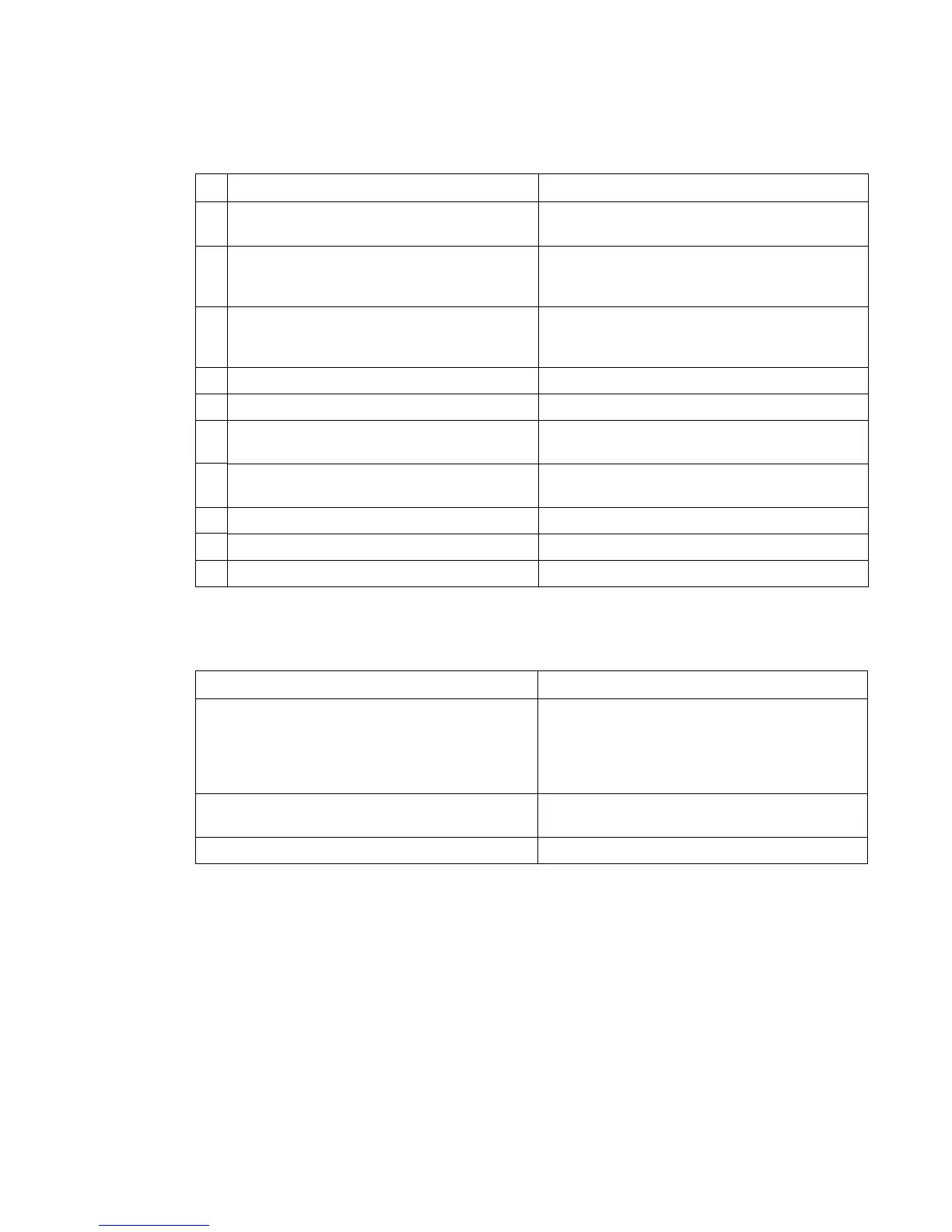

Color misregistration

If the misregistration occurs in a particular color, go to A. If it occurs in all colors, go to step B; otherwise,

perform the steps in order, from the top down.

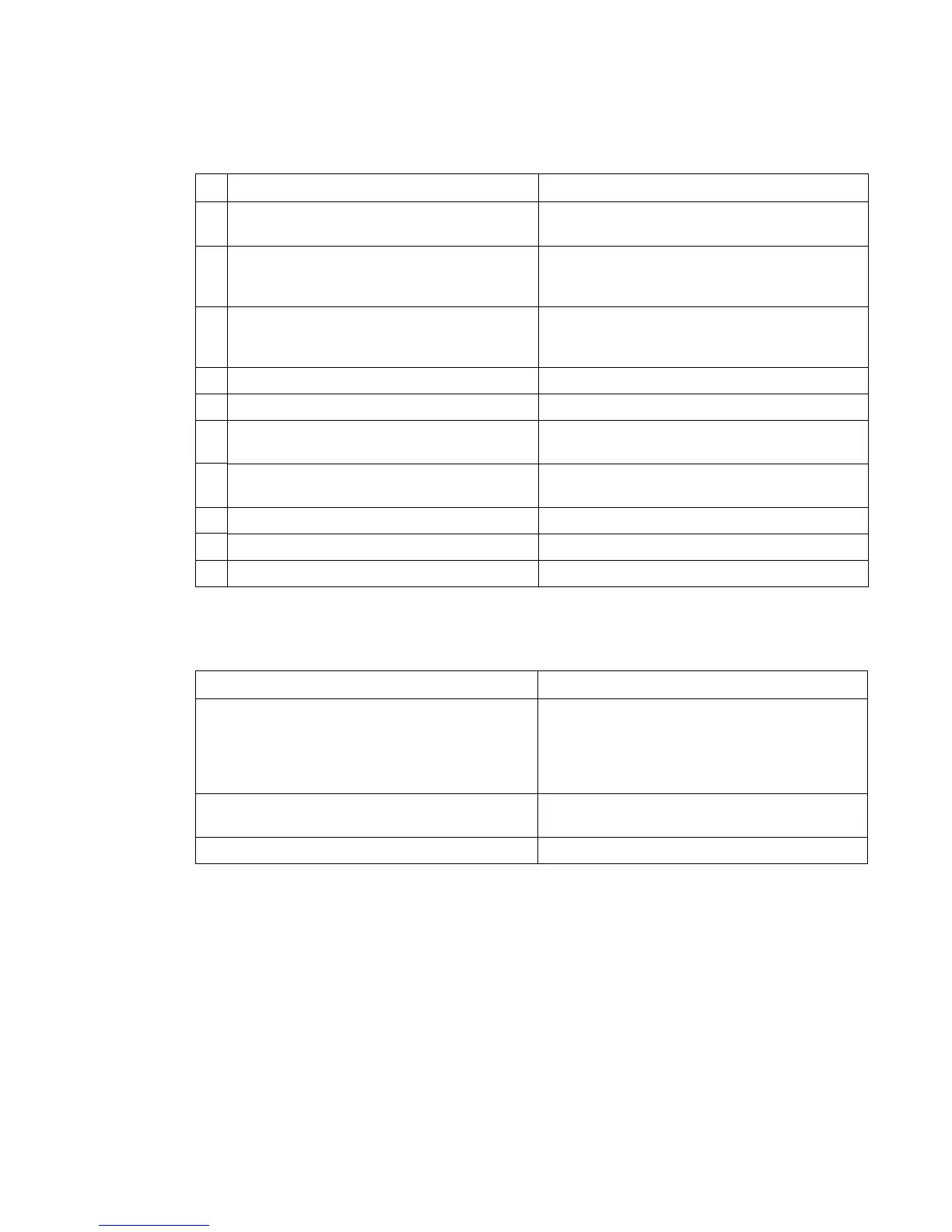

Smearing

Table 7-34 Causes for smearing

Cause Solution

The color misregistration is not properly adjusted. Calibrate the printer. See Calibrate Now, later in this

chapter.

A Defective cartridge. Check if the photosensitive drum in the problem

(misregistered) color’s cartridge rotates smoothly. If

not, replace the cartridge.

Worn/Chipped cartridge drive gears. Check drive gears connected into the problem

(misregistered) color’s cartridge. If worn or chipped,

replace the gear.

B Dirty color misregistration sensor. Clean the lens of the color misregistration sensor.

Defective color misregistration sensor. Replace the color misregistration sensor.

Defective transfer unit. If the transfer unit does not rotate smoothly, replace

the transfer unit.

Worn/Chipped drive gears. Check drive gears between the image drive unit and

the drum motor. If worn or chipped, replace the gear.

Defective image drive unit. Replace the image drive unit.

Defective laser/scanner unit. Replace the laser/scanner unit.

Defective DC controller PCB. Replace the DC controller PCB.

Table 7-35 Causes for smearing

Cause Solution

Poor contacts to each cartridge and printer grounding. Clean the grounding contacts on each cartridge and

the printer. If the problem remains after cleaning,

check contacts for deformation or damage. Replace

parts, if deformed or damaged. Make sure all

contacts are connected correctly.

The movement of the fuser front paper sensor lever is

not smooth.

Reseat the lever to make the movement smooth.

Foreign substances/dirt on the fuser inlet guide. Clean the fuser inlet guide.

Loading...

Loading...