◦

Print A2 sizes in portrait position, using low-width rolls or nesting to minimize waste of paper.

◦

For A3 size, group different jobs in the same plot.

The stacker detects "Stacker is full" permanently

Even when there are no pages in the stacker, it detects that is it full.

●

Run the capacity sensor diagnostic.

●

Run the ramps motor diagnostic.

●

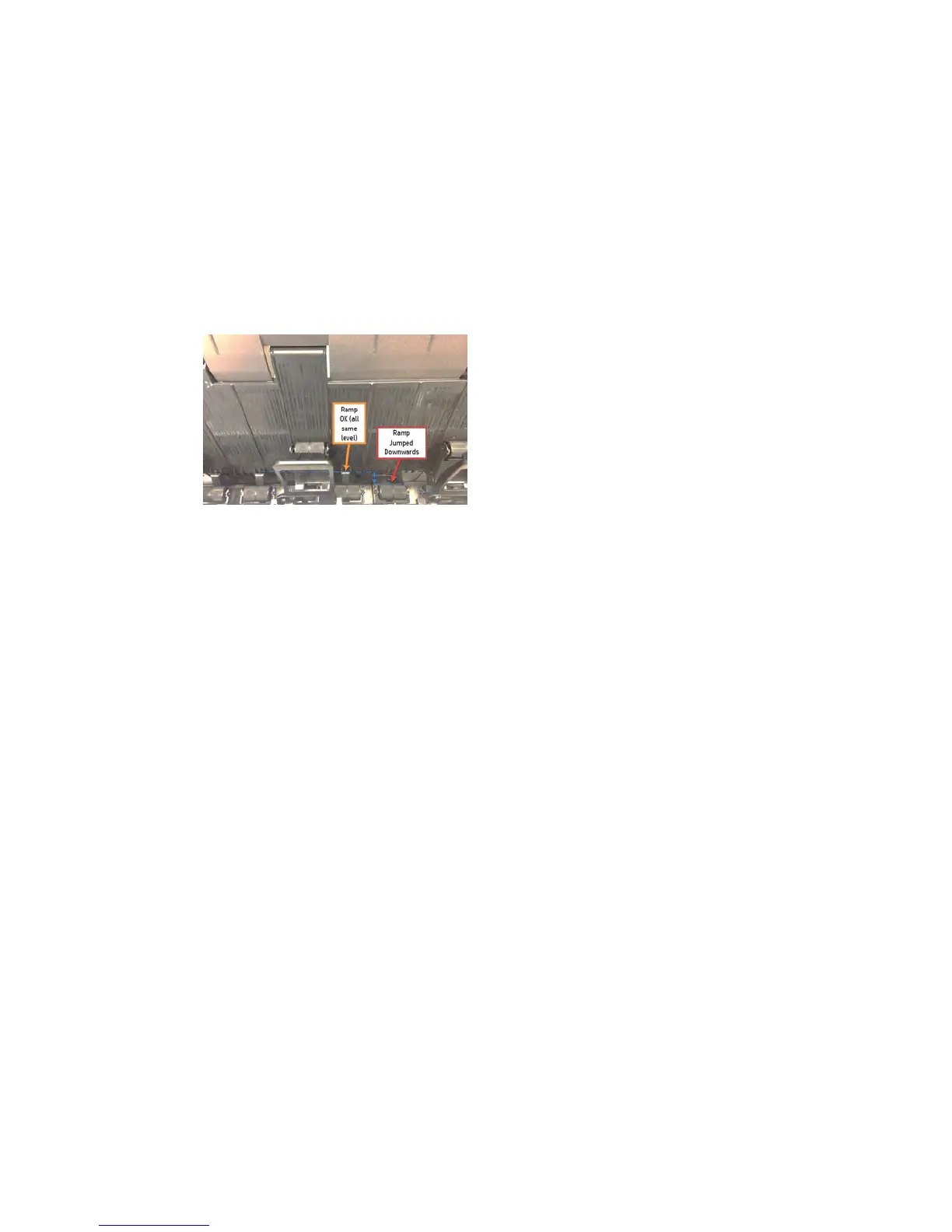

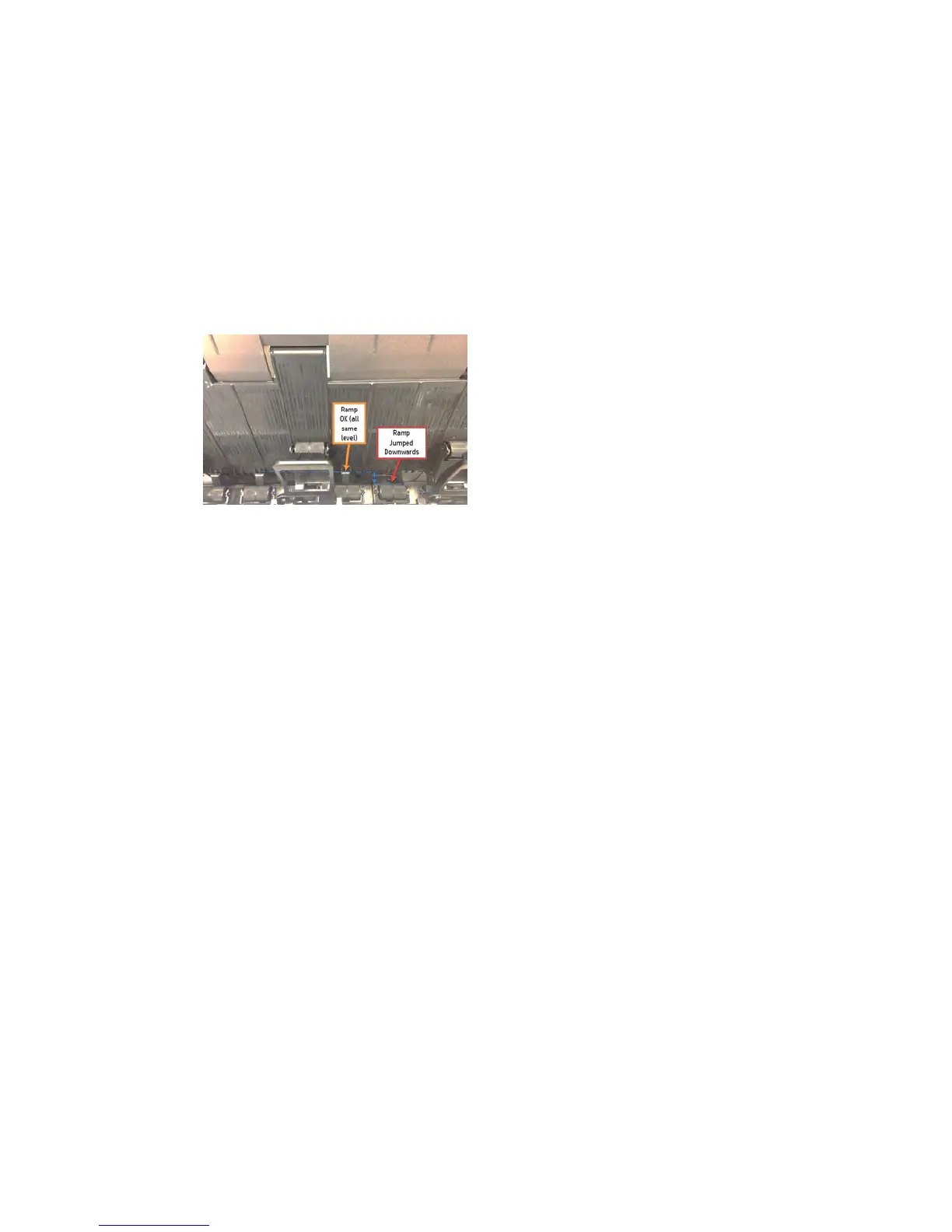

Check that when the ramps are up all are at the same height.

If ramps are not aligned, replace the stacker.

●

Run the capacity sensor diagnostic. If it fails, replace Hand off Assy sensor.

The stacker detects "Stacker jam" permanently

Even when there are no pages in the stacker, it detects a jam.

●

Run the capacity sensor diagnostic. If it fails, replace Hand off Assy sensor.

The printer rejects the paper during paper load

If the roll load process is too long and unsuccessful, check the following items:

●

Roll paper is properly inserted in the spindle and pressed uniformly by the hubs.

●

The core of the roll paper is not misplaced. If this is the case, try to correct its position.

●

Check if the black hub of the spindle is damaged. If any part of the spindle is damaged, it could cause

roll load problems.

If the roll affected is from a polyester or film type, it is possible that the edges of the paper are not properly

detected during the paper load process:

●

Upgrade to the latest FW release to solve the problem, as the paper load algorithm has been improved.

Prints do not fall neatly into the basket

●

Ensure that the network and power cables are not getting in the way.

●

Ensure that the basket is correctly installed.

●

Ensure that the basket is open.

ENWW Paper handling problems 57

Loading...

Loading...