ENWW Chapter 7 Troubleshooting 203

Jam troubleshooting

Jams occur in the printer when print media does not reach or clear a photosensor along the

printer paper path within a specific amount of time. The following table contains general

questions and topics to explore before troubleshooting.

Frequency of jams

Jams in the paper path that occur intermittently are most often related to a deficiency in the

media or environment. See “Media troubleshooting” on page 217 for information about these

defects.

Paper-path jams that occur frequently, and in the same location of the printer, are most likely the

result of a hardware problem.

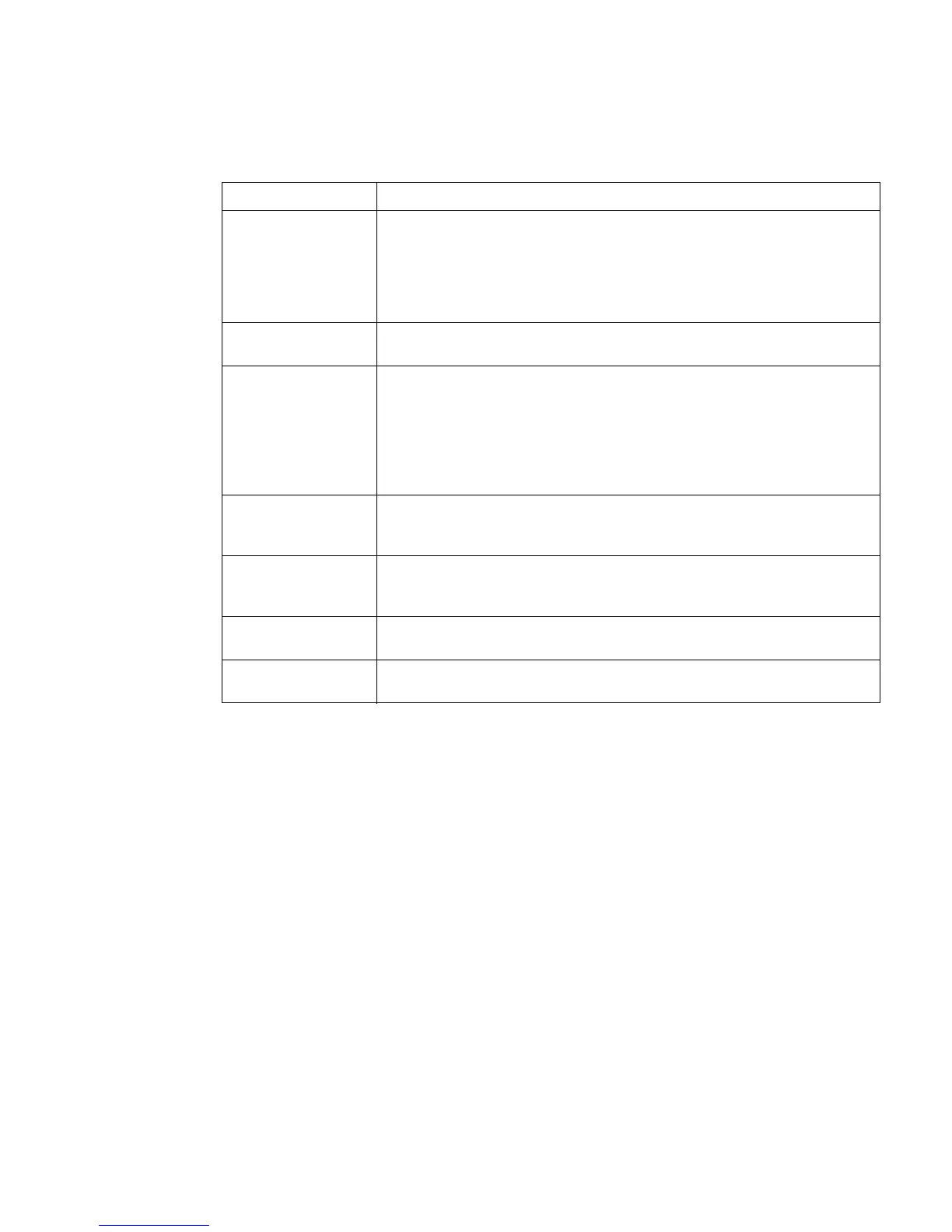

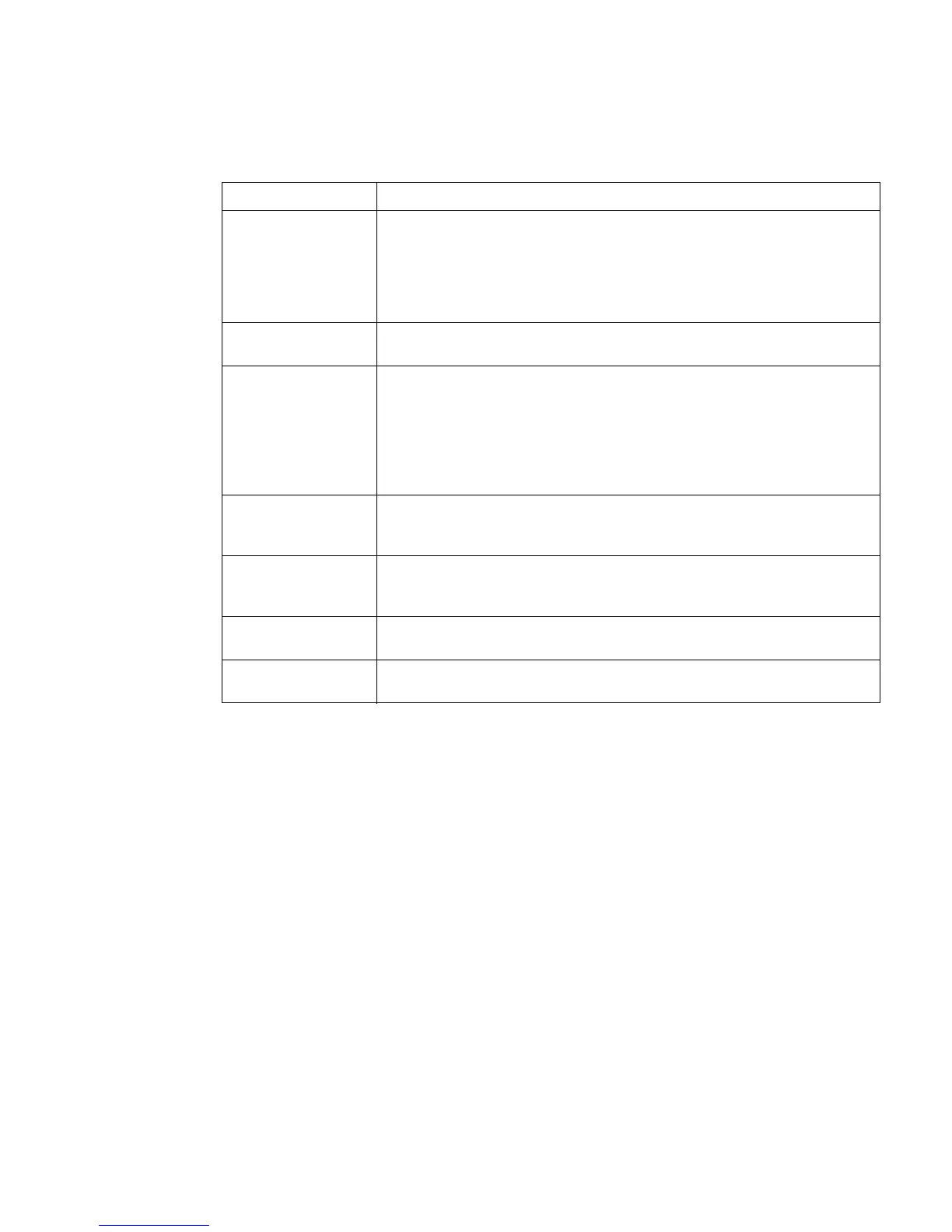

Problem Action

What is the frequency

of the jams (for

example: continuous,

one jam per 100 pages,

one jam per 1000

pages)?

Verify with the customer. See “Troubleshooting with control-panel messages” on

page 184.

Check the event log.

Do jams occur with a

specific type of media?

Try using media that you know is of good quality. See “Media troubleshooting” on

page 217.

Where does the leading

edge of the first sheet

of media in the printer

paper path stop when a

jam occurs? Are any

sheets damaged or

torn?

Attempt to duplicate the problem. Inspect the paper path and all paper path

mechanical assemblies located before the leading edge of the jam.

Is the customer loading

the trays or cassettes

correctly?

Observe the customer loading media. Instruct the customer to break the ream,

and not to fan the media. See “Media troubleshooting” on page 217.

Is the customer

overfilling the trays or

cassettes?

Observe the customer loading media in the trays or cassettes. Make sure that the

media is not over the maximum fill marks in the trays or cassettes.

Are the tray guides set

correctly?

Make sure all front and rear tray 2 and optional 250-sheet or 500-sheet feeder

guides are set correctly.

Does the printer need

cleaning?

Inspect the paper path and paper-path rollers.

Loading...

Loading...