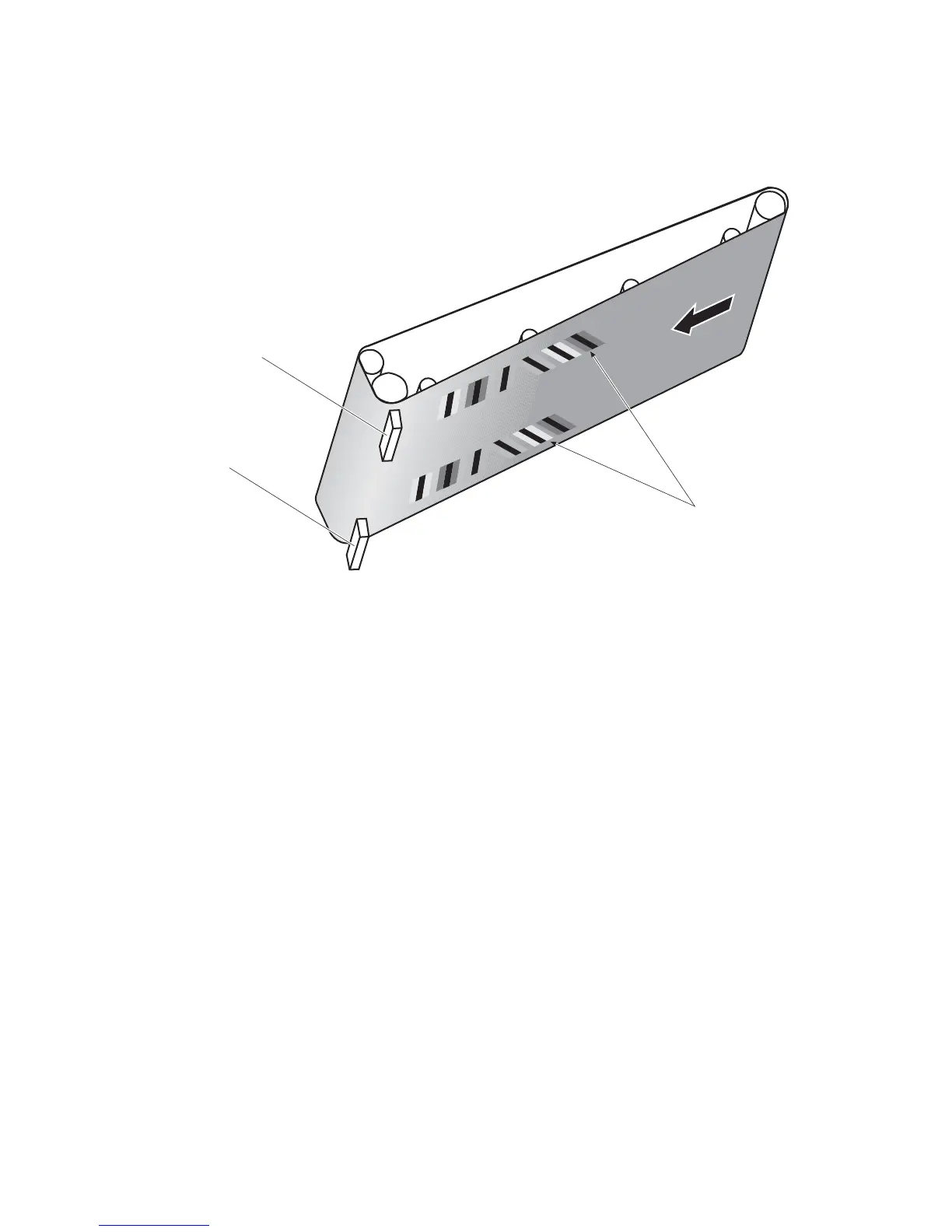

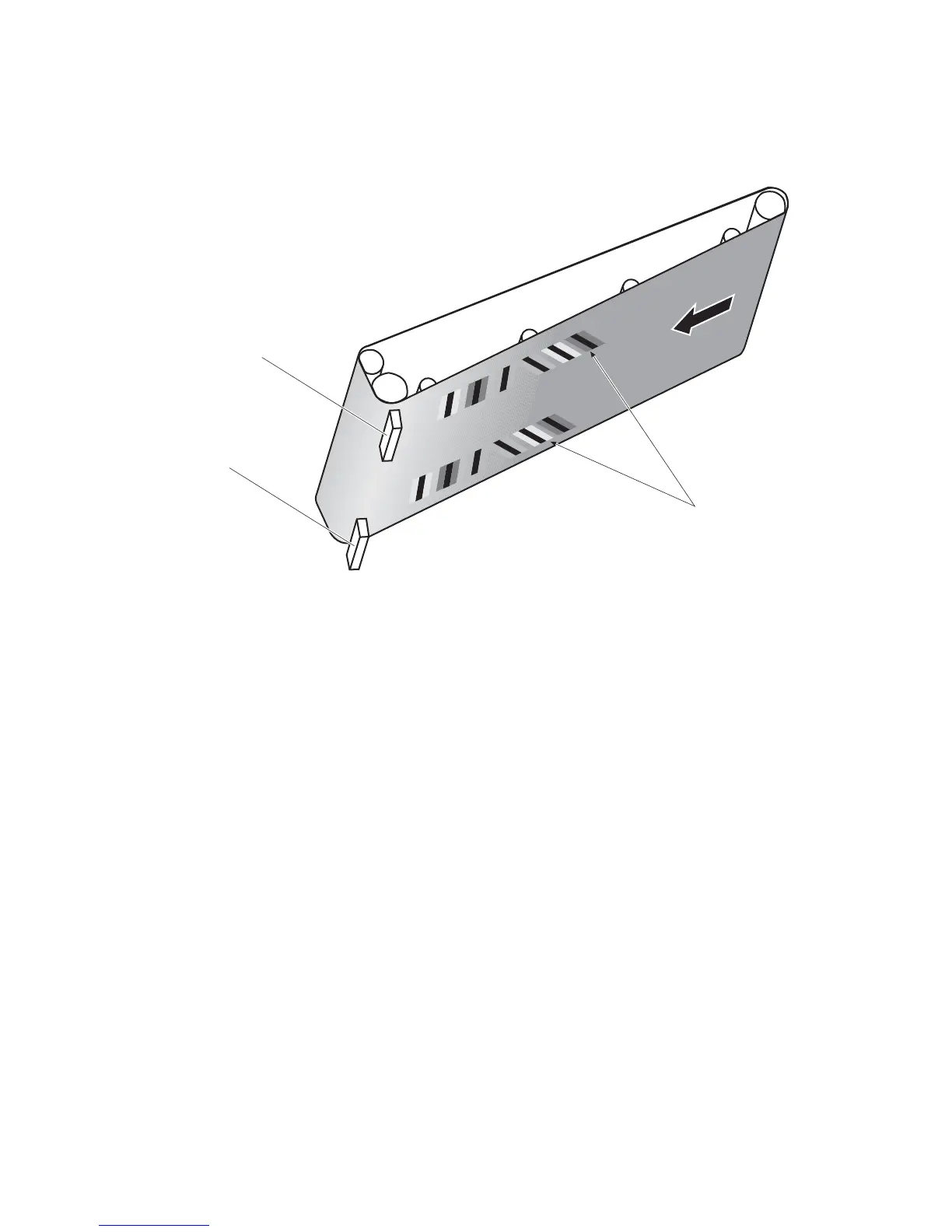

The DC controller forms a pattern of toner on the surface of the ITB, and measures a misaligned length with

the registration density sensor and the registration density belt-perimeter sensor. Accordingly, the formatter

calibrates the color-misregistration.

Figure 1-29 Color-misregistration control

ITB

Pattern of toner

Registration density sensor

Registration density

belt-perimeter sensor

The DC controller commands the formatter to perform the color-misregistration control whenever one of the

following occurs:

●

The product is turned on or the door is closed, after replacing any one of the cartridges

●

The product is turned on or the door is closed, after replacing the ITB unit or the laser scanner unit

●

A specified number of pages have been printed

●

Continuous printing for a specified period of time

●

Cold starting of the fuser when the product is turned on

If data from the registration density or registration density belt-perimeter sensor is out of a specified range

during the cartridge-presence detection or when starting the color-misregistration control, the DC controller

determines an abnormal sensor and notifies the formatter.

Environment change control

The environment change control calibrates each high-voltage bias to obtain an appropriate image according

to the environment changes. The DC controller determines the environment, where the product is installed,

based on the surrounding temperature and humidity data from the environment sensor. It adjusts the high-

voltage biases to accommodate environmental changes.

The DC controller determines an environment sensor abnormality and notifies the formatter when it detects

out of specified range data from the environment sensor.

ENWW Image-formation system 41

Loading...

Loading...