LP-387 Rev. 7.3.15

26

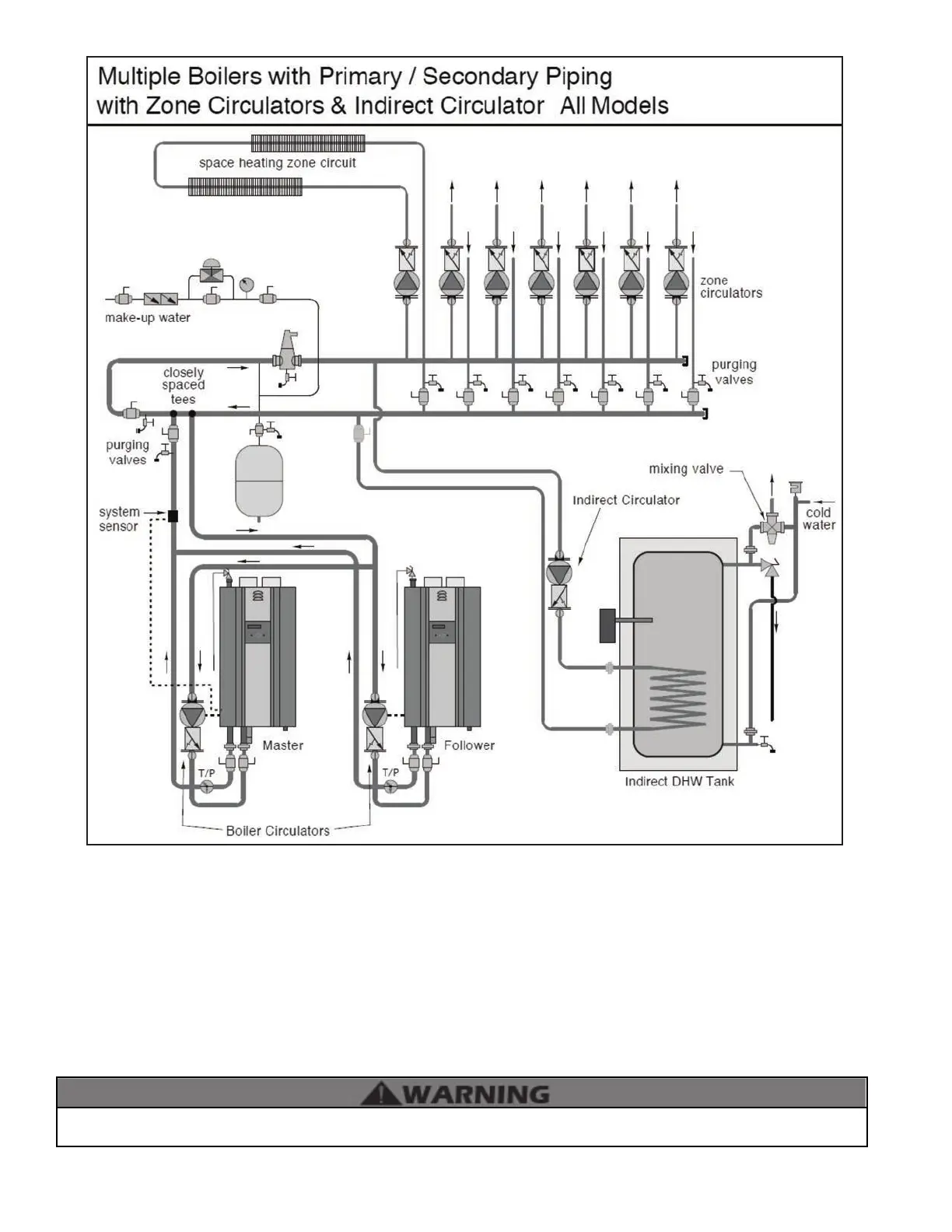

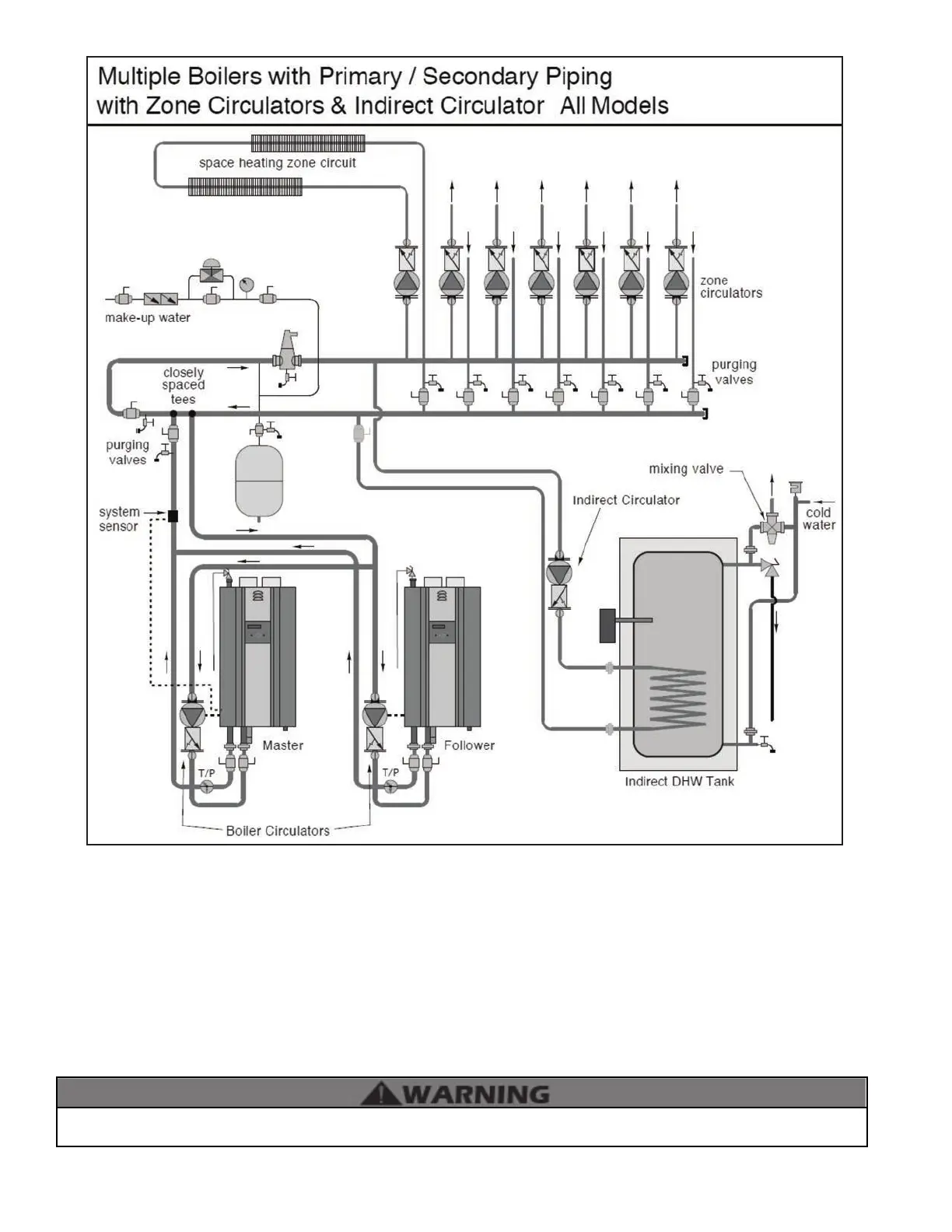

NOTES:

1. This drawing is meant to show system piping concept only. Installer is responsible for all equipment and detailing required by local codes.

2. All closely spaced tees shall be within 4 pipe diameters center to center spacing.

3. A minimum of 6 pipe diameters of straight pipe shall be installed upstream and downstream of all closely spaced tees.

4. The minimum pipe size for connecting an indirect water heater is 1”

5. The minimum pipe size for connecting a 55/80/110 - 1”, 155/199/285 – 1.25”, 399 – 1.5”.

6. Circulators are shown with isolation anges. The alternative is standard anges with full port ball valves. Purge valves can be used with

circulator anges as an alternative.

7. A mixing valve is recommended if the DHW temperature is set above the factory setting of 119

o

F.

8. Piping shown is Primary/Secondary. System ow (secondary loop) must be greater than the boiler’s primary loop ow.

9. Install a minimum of 12 diameters of straight pipe upstream of all circulators.

10. VERY IMPORTANT – Minimum ow rates outlined in this manual must be maintained through the heat exchanger to minimize short cycling.

The piping will not support the weight of the circulators. Refer to the circulator manufacturer’s instructions to properly support

the circulator. Failure to comply with these instructions could result in property damage, severe personal injury, or death.

Figure 14 - Multiple Boilers - Primary / Secondary Piping with Pumps and Indirect Priority

Loading...

Loading...