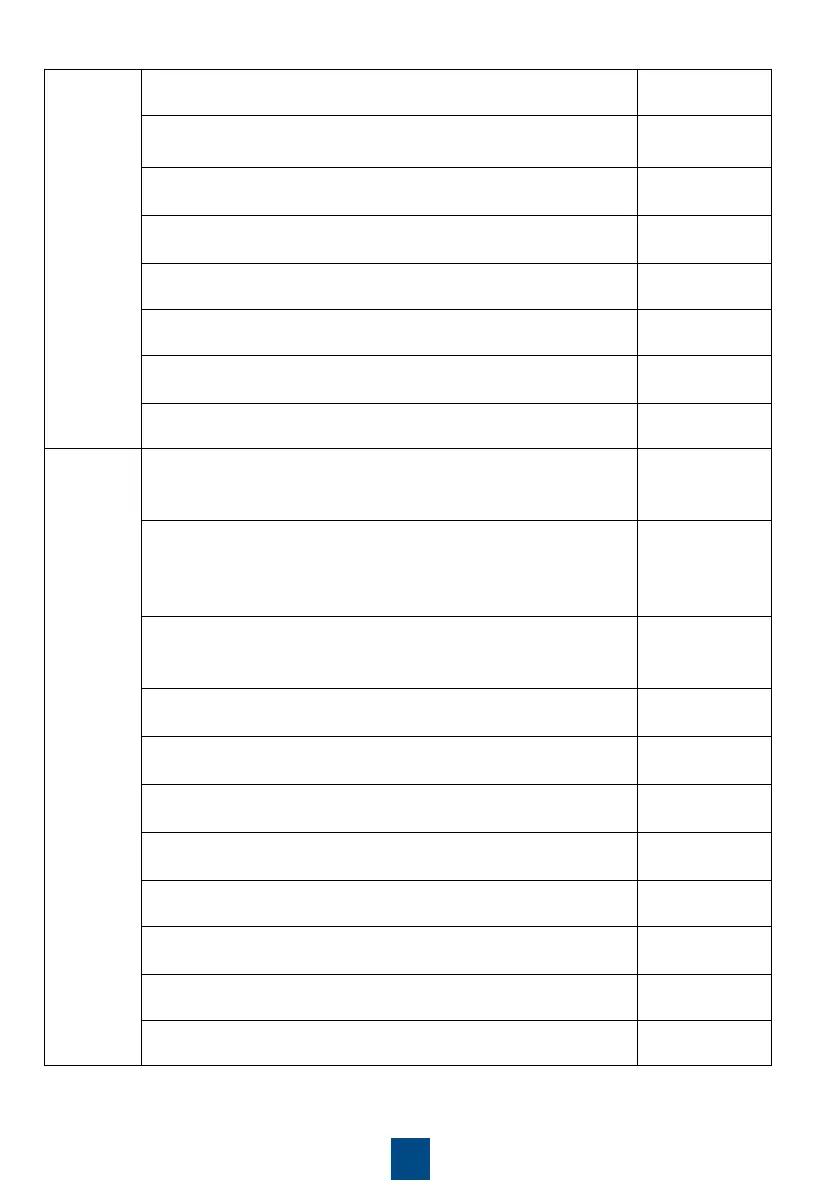

All cable joints are secured properly, especially the cable joints of

network cables.

Failed

Exposed parts of cables and cable lugs near the cable terminals

are wrapped with insulation tape or heat-shrink tubing.

Failed

Flat washers and spring washers of all wiring terminals are

securely installed and in good contact.

Failed

Cables are bound neatly, and cable ties are secured evenly and

properly in the same direction.

Failed

Excess sections of cable ties are neatly cut.

Failed

There is no unnecessary adhesive tape or cable tie on cables.

Failed

Cables are routed in a way convenient for maintenance and

future capacity expansion.

Failed

Labels at the cable ends are clear.

All ground cables are copper cables with diameters meeting the

requirements. No switch or fuse is installed on a ground cable,

and no open circuit occurs.

Failed

All ground cables, AC input cables, and intra-cabinet cables are

connected correctly according to the power system circuit

diagram, and all screws are fastened. The input and output

cables are not short-circuited.

Failed

The smart cooling product input voltage is within the range of

rated voltage

±

10%, and the input frequency is within the

range of rated frequency

±

3 Hz.

Failed

Power cables and ground cables are not coiled and excess parts

are cut off.

Failed

Lugs for power cables and ground cables are welded or crimped

securely.

Failed

Power cables and ground cables are routed and bound

separately from other cables.

Failed

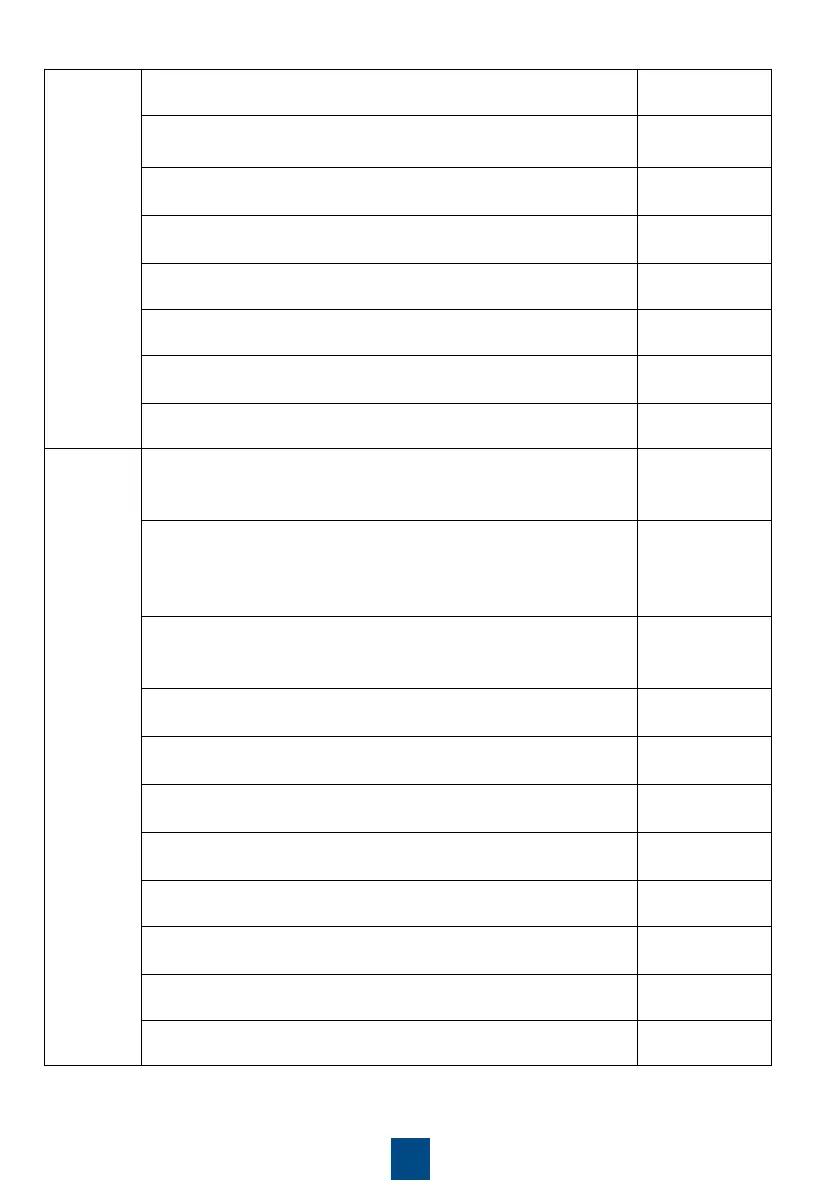

Lithium batteries are intact, free from damage, cracks, and

bulges.

Failed

Lithium batteries are neat and clean, and do not leak electrolyte.

Failed

Lithium battery terminals are upright and free from damage,

break, and acid leakage.

Failed

Lithium battery cables are connected correctly.

Failed

DIP switches on devices are correctly set.

Loading...

Loading...