24

LOW WATER CUT-OUT

1. Due to the low resistivity of DI/RO water, a 316L stainless steel float type low water cut-

out is supplied in lieu of a conductivity type. This device will help protect the elements

from energizing when there is insufficient water in the tank. The float type low water cut-

out will disengage the control circuit during low/no water conditions and will auto-reset

when the water reaches a safe level. The conductivity low water detection system

incorporated in the T1000 digital controller should be disabled for DI/RO water

applications.

DISPLAY BUTTONS

1. If the display randomly changes or does not respond when the buttons are pressed,

loosen the four (4) screws holding the display to the base, reseat the display in the

center of the opening, and re-tighten the screws.

MISCELLANEOUS

1. If the display flashes when the unit is first turned on or turned on after maintenance,

check that the J5 terminal on the controller is engaging all four pins on the board.

2. Note that before replacing the control board, display, or probe, it is recommended that

the power supply to the heater be turned off at the main circuit breaker disconnect to

the heater to reset and clear the electronic controller.

GENERAL TROUBLESHOOTING

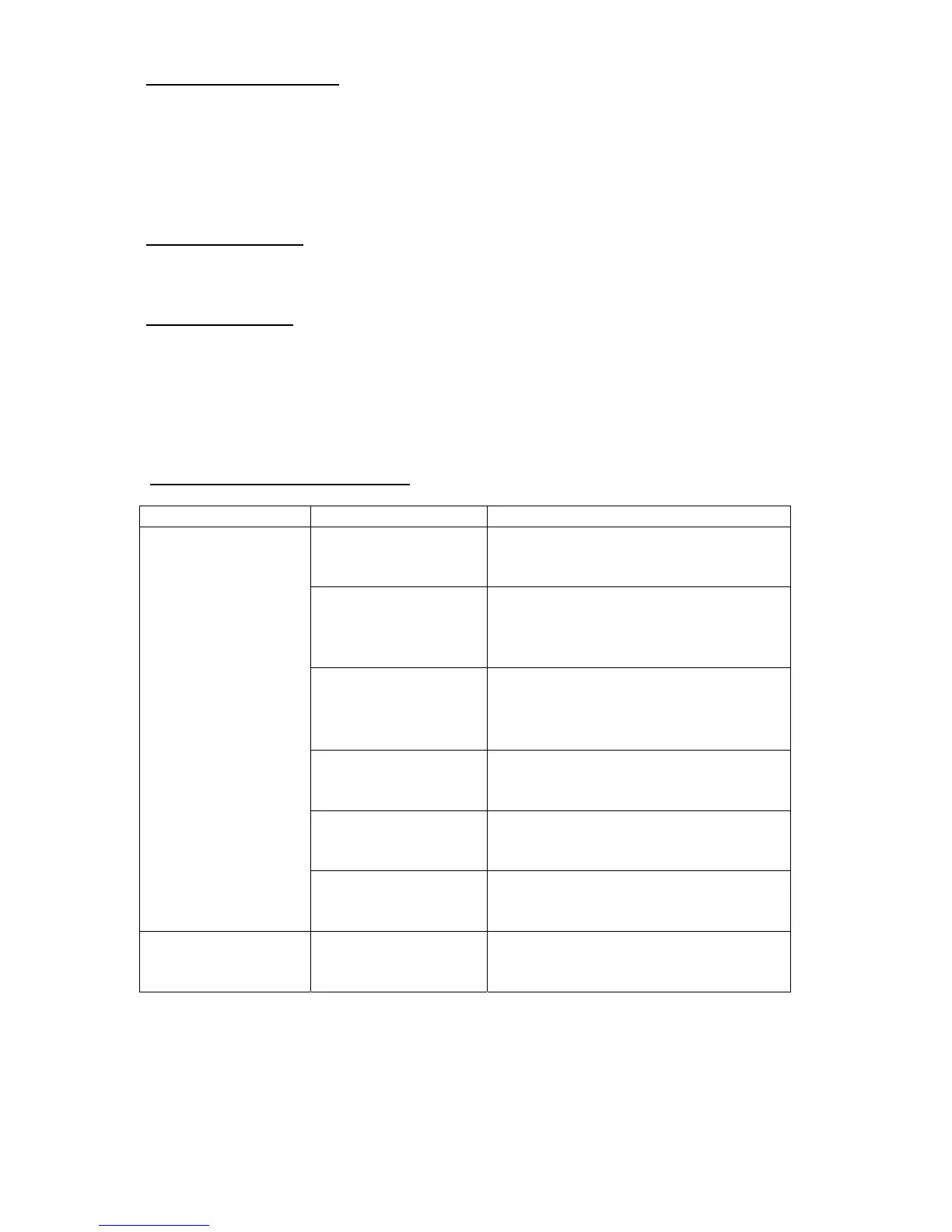

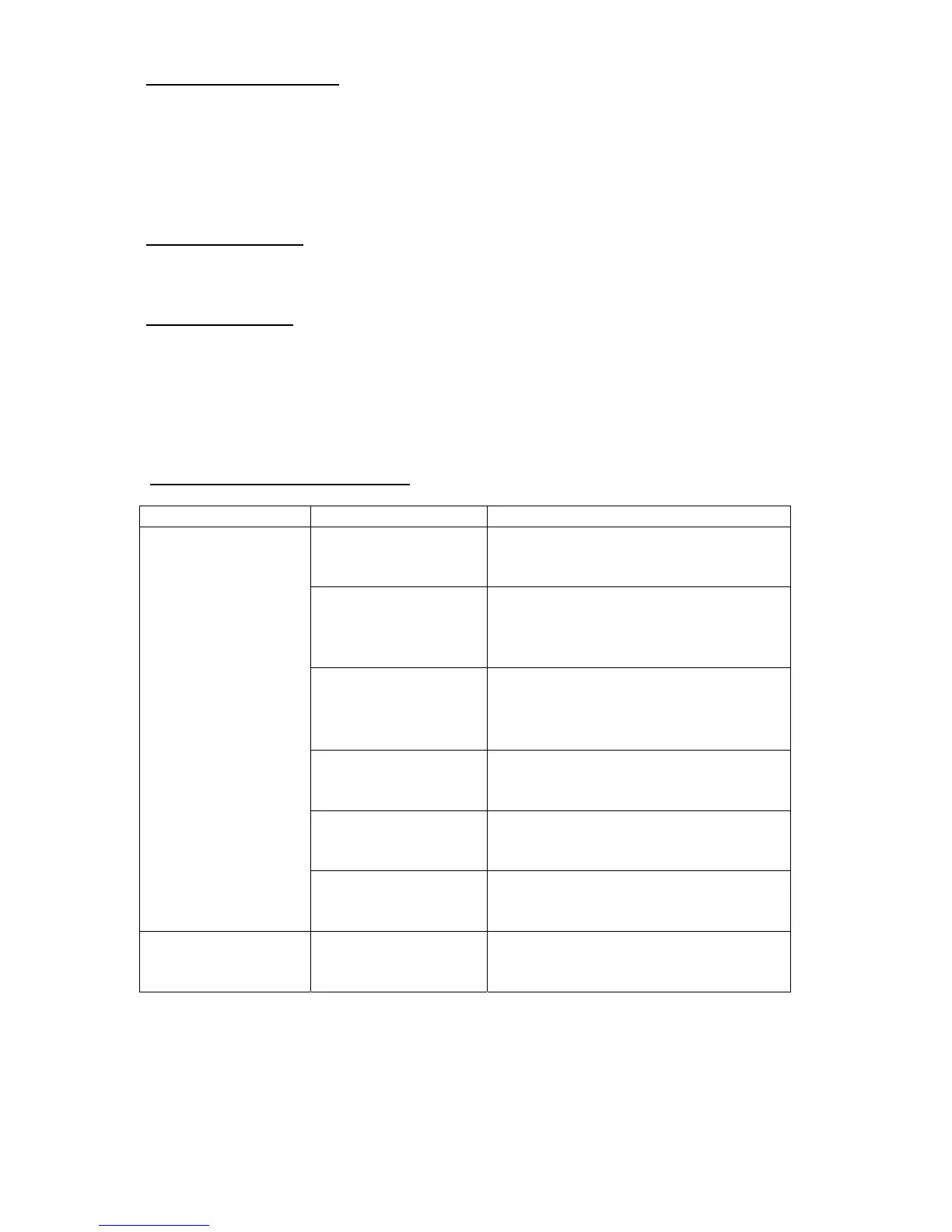

Symptom Probable Cause Corrective Action

Water reaches setpoint

temperature but does

not last through the

entire process cycle.

Low incoming water

temperature.

Incoming water temperature must be

adequate for the heater size. Increase the

incoming water temperature.

Incoming water

temperature is dropping.

Primary water supply is not adequate to

continually provide correct temperature in

sufficient quantities. Increase the supply of

primary cold water.

Heater may be

undersized.

The heater must be properly sized for the

incoming water and rinse requirements of

the process. If required, replace with a

properly sized unit.

Incorrect voltage. Voltage available at the heater must be

correct for unit. Verify voltage on all

phases matches nameplate on the heater.

If two magnetic

contactors are utilized,

one is not energizing.

Verify that both magnetic contactors are

operating. If not, see the ‘Magnetic

Contactor Troubleshooting’ section.

One or more elements

are not energizing.

Verify that each element is drawing the

correct amperage. Replace elements as

required.

Temperature and

pressure relief valve

seeps.

Anti-siphon valve or

check valve installed in

the cold water inlet line.

Remove the anti-siphon valve or the check

valve to allow for the expansion of the

water or install a back pressure relief valve.

Loading...

Loading...