HUNTER

closed usually indicates a leak somewhere

in the lines. Trace the lines to locate the

leak and correct.

STOVE OPERATION

Follow the operating instructions sup-

plied with the unit installed with your

boat.

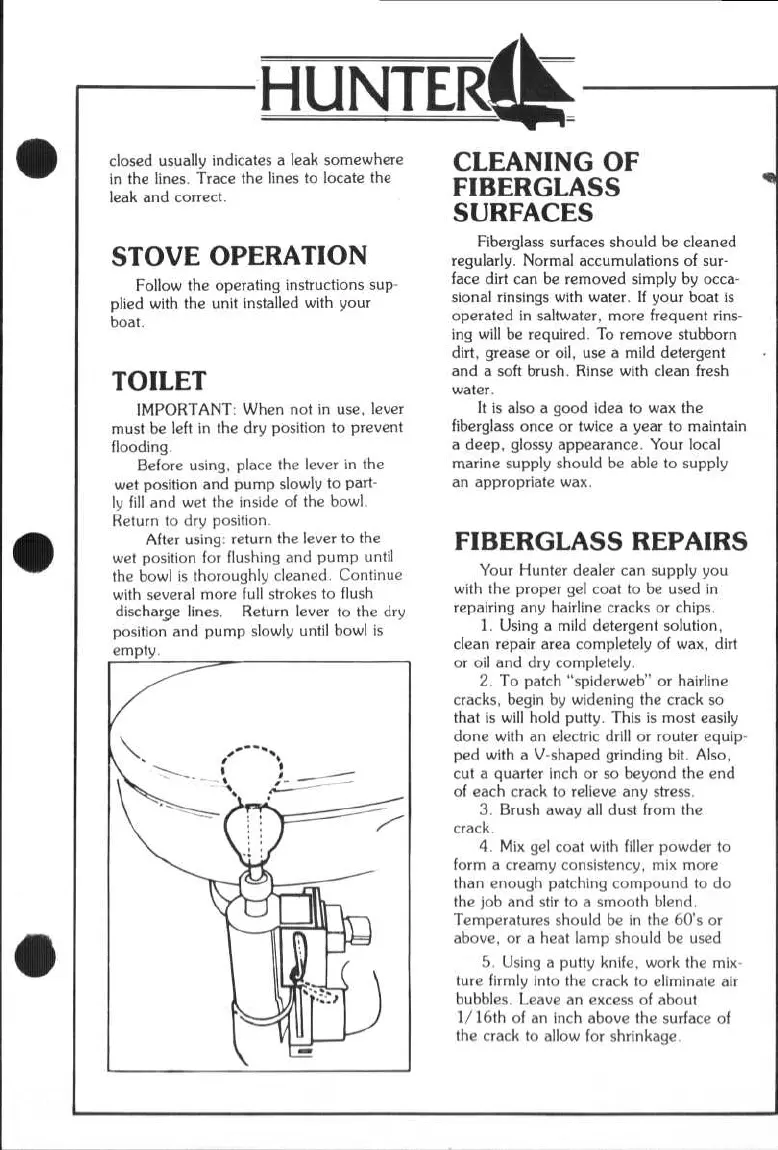

TOILET

IMPORTANT: When not in use, lever

must be left in the dry position to prevent

flooding.

Before using, place the lever in the

wet position and pump slowly to part-

ly fill and wet the inside of the bowl.

Return to dry position.

After using: return the lever to the

wet position for flushing and pump until

the bowl is thoroughly cleaned. Continue

with several more full strokes to flush

discharge lines. Return lever to the dry

position and pump slowly until bowl is

empty.

CLEANING OF

FIBERGLASS

SURFACES

Fiberglass surfaces should be cleaned

regularly. Normal accumulations of sur-

face dirt can be removed simply by occa-

sional rinsings with water. If your boat is

operated in saltwater, more frequent rins-

ing will be required. To remove stubborn

dirt, grease or oil, use a mild detergent

and a soft brush. Rinse with clean fresh

water.

It is also a good idea to wax the

fiberglass once or twice a year to maintain

a deep, glossy appearance. Your local

marine supply should be able to supply

an appropriate wax.

FIBERGLASS REPAIRS

Your Hunter dealer can supply you

with the proper gel coat to be used in

repairing any hairline cracks or chips.

1.

Using a mild detergent solution,

clean repair area completely of wax, dirt

or oil and dry completely.

2.

To patch "spiderweb" or hairline

cracks, begin by widening the crack so

that is will hold putty. This is most easily

done with an electric drill or router equip-

ped with a V-shaped grinding bit. Also,

cut a quarter inch or so beyond the end

of each crack to relieve any stress.

3.

Brush away all dust from the

crack.

4.

Mix gel coat with filler powder to

form a creamy consistency, mix more

than enough patching compound to do

the job and stir to a smooth blend.

Temperatures should be in the 60's or

above, or a heat lamp should be used

5.

Using a putty knife, work the mix-

ture firmly into the crack to eliminate air

bubbles. Leave an

excess

of about

1/16th of an Inch above the surface of

the crack to allow for shrinkage.

Loading...

Loading...