English – 3

EN

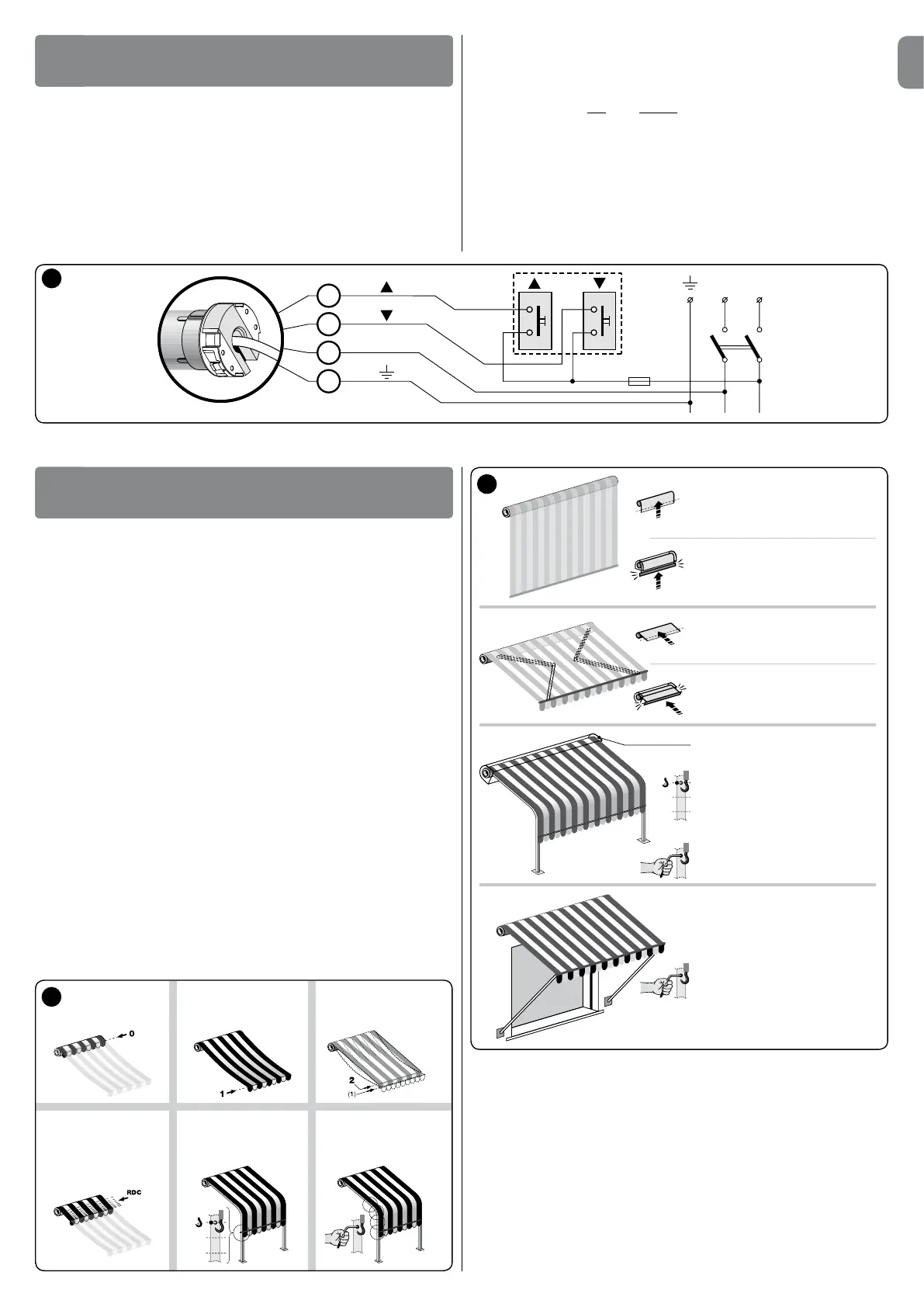

5.1 - Programming warnings

• In general

-Strictlyobservethetimelimitsspeciedintheprocedures.

- Positions 0, 1, 2, and Softheawning,speciedinthetext,correspondtothose

illustrated in g. 5.

• Motor signals

o The motor implements one very short interruption at the start of the ma-

noeuvre and then resumes movement = only 1 limit switch is memorised.

o The motor implements two very short interruptions at the start of the

manoeuvre and then resumes movement = no limit switch is memorised.

o when the control button is pressed (“hold-to-run” mode), movement is

started but is interrupted shortly afterwards, without completing the ma-

noeuvre = proceed with total deletion followed by programming of the limit posi-

tions.

5.2 - Limit switch programming

Limit switches “0” and “1” (g. 5) correspond to the positions of the awning at the

endoftheUpmovements(“0”)andtheendoftheDownmovements(“1”).

To select the procedure most suited to the system features, refer to g. 6.

• Note on “RDC” function

The RDCfunctionpreventsthecanvasfromremainingexcessivelytensionedatthe

end of the closing ma noeuvre. The function automatically reduces the motor traction

torqueduringthenalphaseoftheclosingmanoeuvre(tosettherequiredtorque

value, refer to paragraph 5.5).

This function is set at the factory, however it is not applicable if the limit switches are

programmedusingthemanualmode(paragraph5.3).Itcanbedisabledonlydur-

ing the programming of the limit switches in semi-automatic mode (paragraph 5.4).

6

Manual procedure

paragraph 5.3

Semi-automatic procedure

paragraph 5.4

Manual procedure

paragraph 5.3

Semi-automatic procedure

paragraph 5.4

Semi-automatic procedure

paragraph 5.4

“FTC”

option (paragraph 5.7)

“FTA” option (paragraph 5.8)

Manual procedure

paragraph 5.3

“FTA” option (paragraph 5.8)

5

position “0” position “1”

Force reduction on

closure (function

“RDC”)

position “2”

Fabric tensioning

(function “FRT”)

position “S”

Automatic hook-up

(function “FTC”)

Manual hook-up

(function “FTA”)

Caution!

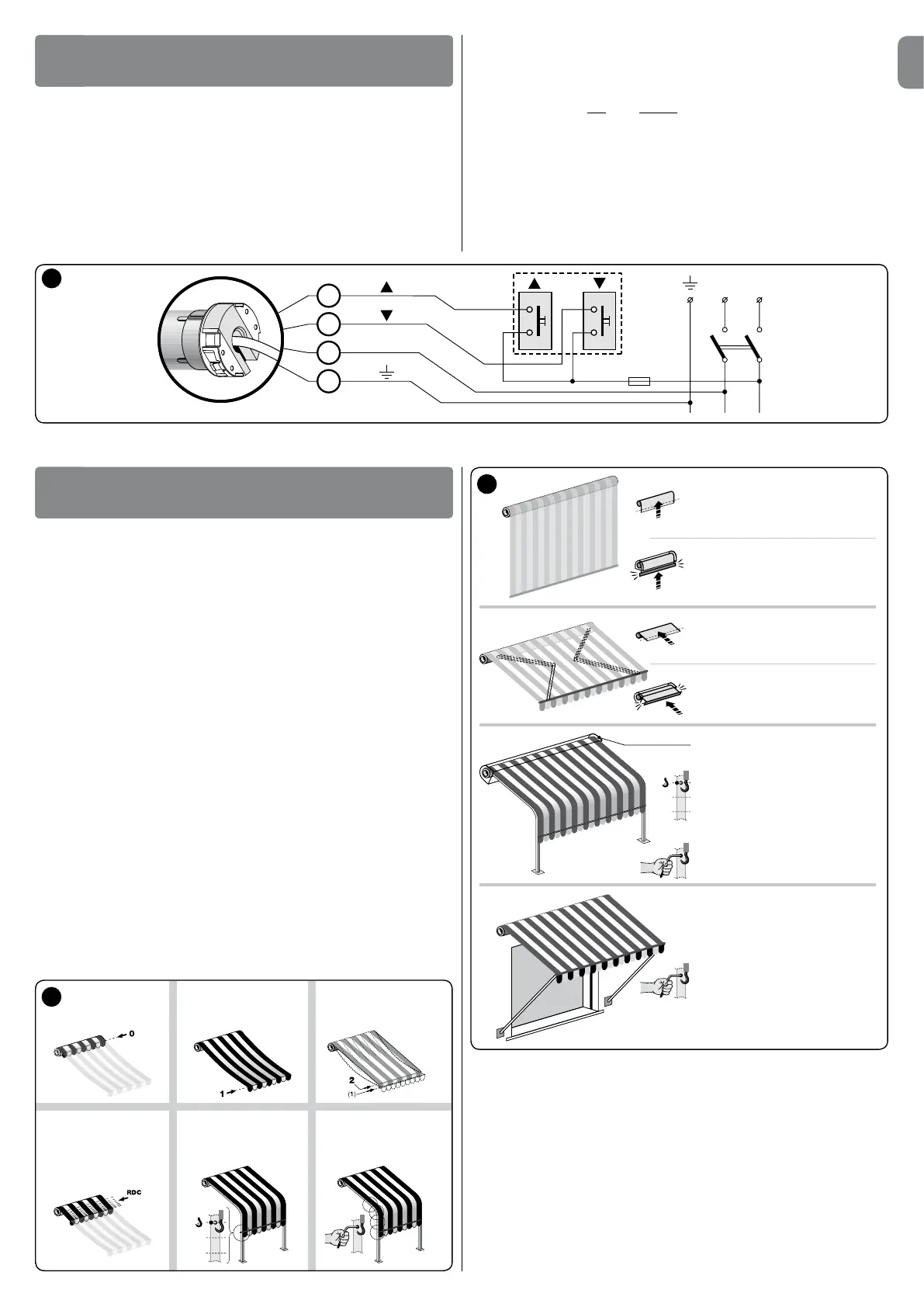

-Incorrectconnectionscancausefaultsorhazardoussituations.

-Strictlyobservetheconnectionsspeciedinthismanual.

- A disconnect device must be installed on the product power supply line, with a gap

betweencontactstoensurecompletedisconnectioninovervoltagecategoryIII,in

compliance with installation regulations (the disconnect device is not supplied with

the product).

For electrical connections, refer to the wiring diagram in g. 4. More than one

motor can be controlled with one single pushbutton control panel by connecting

the motors “in parallel”The cable for electrical connections of the tubular motor has

4 internal wires:

ELECTRICAL CONNECTIONS

4

PROGRAMMING

5

Brown

Black

Blue

Yellow-green

– Brown: = electric ascent/descent phase.

– Black: = electric descent/ascent phase.

– Blue: = Common (usually connected to Neutral).

– Yellow-green: = Earth (equipotential bonding connection).

• Associating the Up and Down movements with the respective

pushbuttons

After making the connections, run a number of manoeuvres (*) to ensure that the

ascent and descent movements are associated correctly with the respective control

buttons.Ifthisisnotso,inverttheconnectionoftheBrown and Black wires.

(*)–Duringexecutionofthemanoeuvre,ensurethattheawningcompletes2short

movements (= operator connected correctly). The direction of motor rotation is not

important.

4

Loading...

Loading...