Do you have a question about the Husqvarna 1010 and is the answer not in the manual?

Specific electrical checks and adjustment procedures for the 6570 model of the sewing machine.

Outlines routine service checks and necessary adjustments for maintaining sewing machine performance.

Details the electrical wiring connections for terminal blocks and foot controls on the sewing machine.

Describes the upper thread tension device, including the tension knob, spring, and discs, and how to adjust it.

Procedures for correctly installing the slide bearing after removal.

Specific instructions for installing the worm wheel, ensuring proper alignment and fit.

Detailed steps for removing the pattern mechanism, including specific components and observations.

Steps for installing the bobbin spindle, ensuring correct alignment and operation.

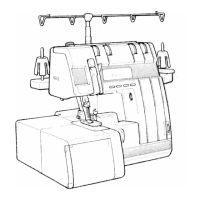

| Brand | Husqvarna |

|---|---|

| Model | 1010 |

| Category | Sewing Machine |

| Language | English |