Do you have a question about the Husqvarna 1020 and is the answer not in the manual?

Specific electrical checks and adjustments required for the 6570 model.

Details on routine service checks and necessary adjustments for optimal performance.

Explains the fundamental process by which stitches are formed on the sewing machine.

Discusses different types of seams created by the machine and their formation.

Details the design and construction of the Viking shuttle system.

Explains the types of bearings used and their precision manufacturing.

Details the adjustment and function of the upper thread tension system.

Explains the role of presser feet in holding fabric during sewing.

Describes the mechanisms for controlling the sewing machine's speed.

Explains the mechanism that controls the length of the stitch.

Details the operation and adjustments for the buttonhole mechanism.

Details the acceptable tolerances for the worm wheel.

Information and checks related to the foot control unit.

Procedure for setting and checking the lowest motor speed.

Procedure for timing the zigzag movement of the needle.

Procedure for centering the maximum zigzag stitch width.

Adjusting the needle's front-to-rear position.

Ensuring the correct left needle position for stitch formation.

Procedure for centering the needle position for optimal stitch formation.

Details on setting the correct height of the needle bar.

Ensuring the needle bar is properly aligned with the stitch plate.

Critical clearance adjustments between the needle and the hook.

Procedure for timing the shuttle hook relative to the needle.

Adjusting the clearance of the shuttle cover for proper operation.

Ensuring the feed teeth are correctly aligned with the stitch plate.

Centering the feed teeth from left to right within the stitch plate.

Aligning the feed teeth in the front-to-rear direction.

Ensuring the stitch plate is level relative to the feed teeth.

Detailed steps for setting the upper thread tension correctly.

Procedure for setting the correct thread tension in the bobbin case.

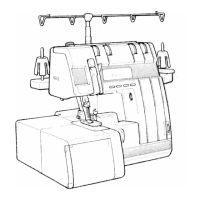

| Brand | Husqvarna |

|---|---|

| Model | 1020 |

| Category | Sewing Machine |

| Language | English |