HUSSMANN CORPORATION • BRIDGETON, MO 63044-2483 U.S.A.

VRL Merchandisers

P/N 3034040_H 15

REPLACING REFRIGERATION SYSTEM

COMPONENTS

STEPS TO RECOVER REFRIGERANT

1. Make sure you are in a well ventilated area be-

fore making any service or repair to the refriger-

ation system.

2. Disconnect all power sources from the system.

Some systems may have more than one plug or

power supply.

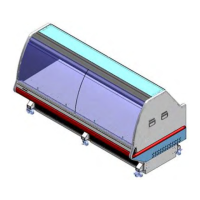

3. Tap system with line tap valves, attaching gauges to

the high and low sides of the system.

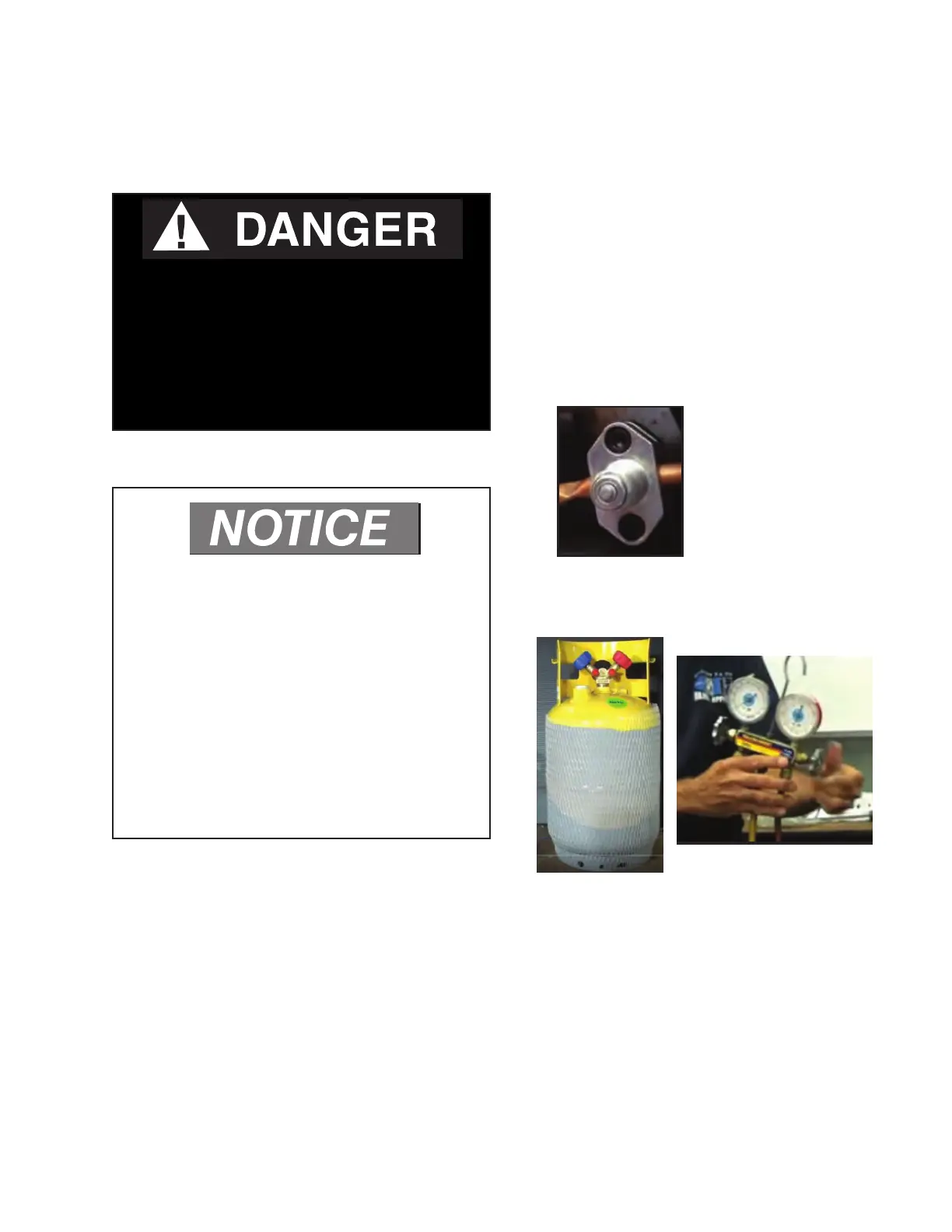

4. Connect hose to an evacuated recovery tank.

Open refrigeration gauges and recovery tank.

5. With the suction valve in vacuum, the refrigerant will

be recovered into the recovery tank.

6. Once recovered, close the tank valve and remove

the guage from the tank and connect nitrogen tank

to the system to purge it with nitrogen.

7. Pull vacuum to a minimum of 200 microns or

lower.

Only Hussmann service technicians or

technicians qualied to handle R-290

(propane) refrigerant should service or

repair this R-290 (propane) equipment

Failure to follow instructions can result

in an explosion, death, injury and

property damage.

refrigeration

line tapping

valve

For VRL merchandisers with a serial

number starting with MY19C or earlier,

there may be a solenoid valve in place on

the liquid line between the condenser coil

and the lter drier. This is a normally closed

solenoid. When the unit is deenergized,

refrigerant can become trapped between

the compressor and this valve. When

removing the refrigerant from the system,

line tap valves must be placed between the

compressor and this solenoid valve as well

as on the low side of the system.

Loading...

Loading...