4-2 109627_0910

particle are abrasive to close-tolerance engine and hydraulic

assemblies.

Daily inspect mower for grass clippings and wire and

string tangles. The underside of the mower deck will collect

a build-up of grass clippings and dirt, especially when grass

is wet or has high moisture content. This build-up will

harden, restricting blade and air movement and will probably

show a poorer quality of cutting. Therefore it should be

removed routinely.

To do this it will be necessary to raise and block the deck,

using jack stands or blocks, in the full up position and scrape

the build-up from underneath. Refer to the deck owner’s

manual for more detailed information.

Some repairs require the assistance of a trained service

mechanic and should not be attempted by unskilled

personnel. Consult your Hustler service center when

assistance is needed.

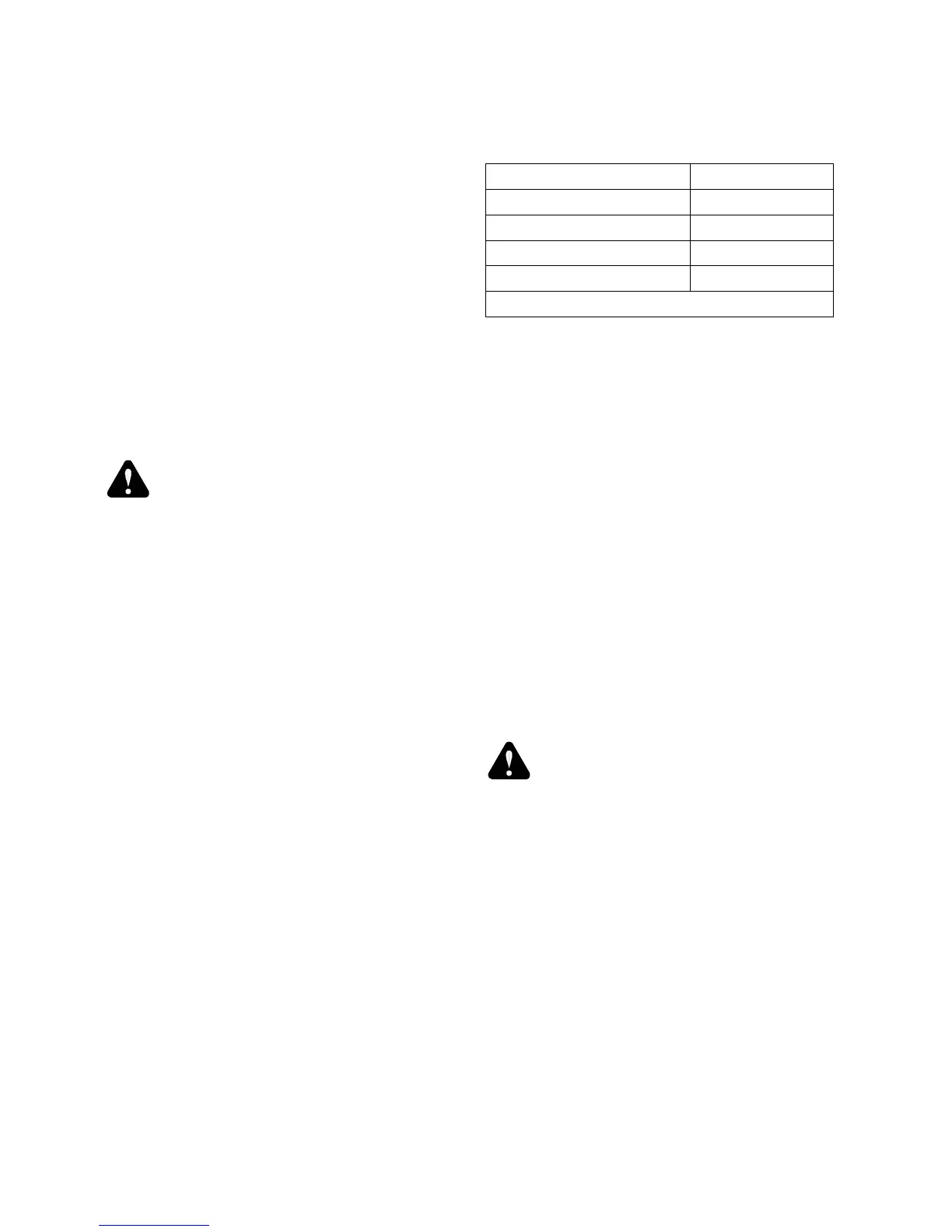

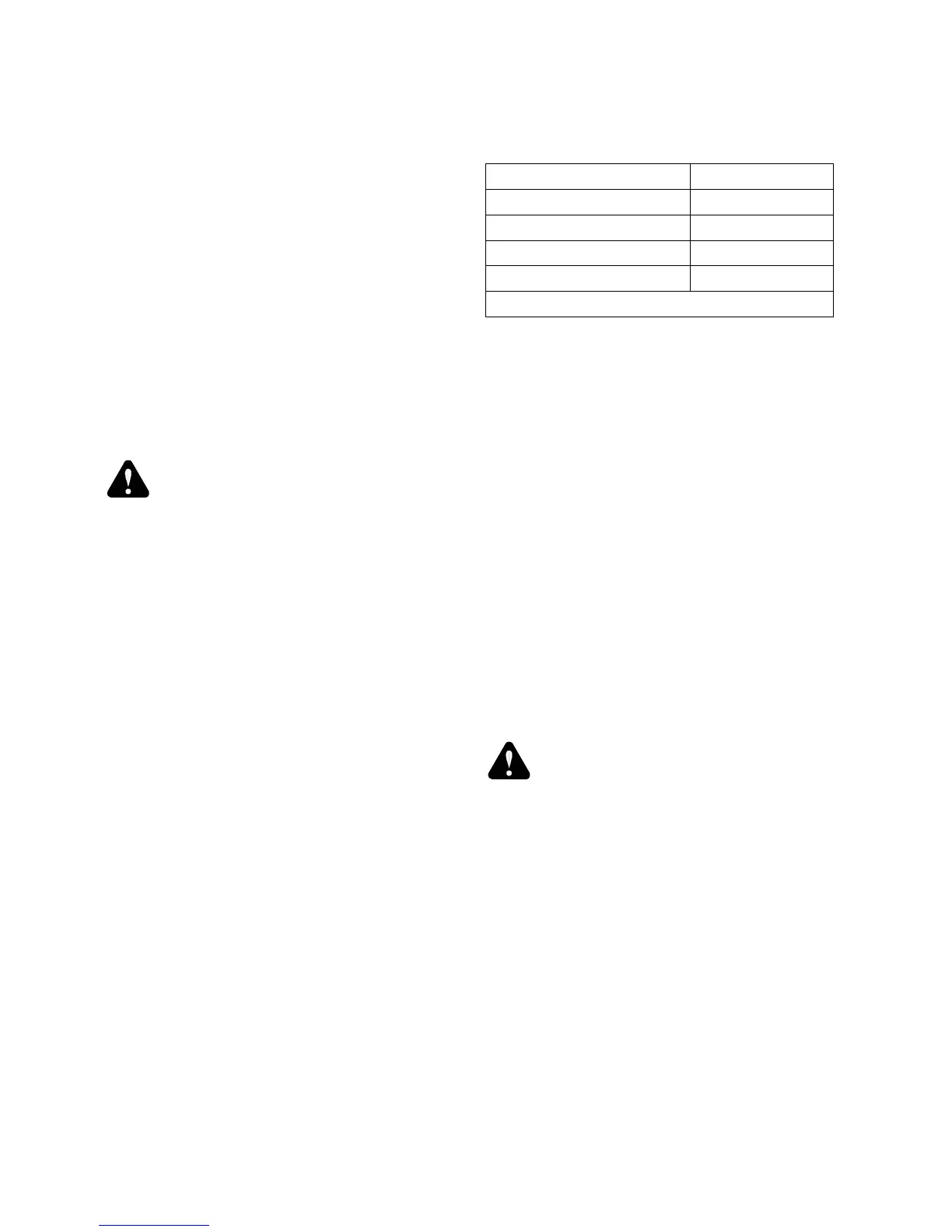

Torque values

IMPORTANT:

WARNING: Particular attention must be given to

tightening the drive wheel lug bolts and blade spin-

dle bolts. Failure to correctly torque these items

may result in the loss of a wheel or blade, which

can cause serious damage or personal injury.

Torque values are given below:

Ft-lbs. Nm

Wheel (lug) bolts - front . . . . 85-95 . . . . . . 115-129

Wheel (lug) bolts - rear . . . . . 65-75 . . . . . . 88.1-101.7

Deck blade (top) bolts . . . . . . 65-75 . . . . . . 88.1-101.7

Deck blade (bottom) bolts . . . 118 . . . . . . . . 160.01

Lug bolts only - It is recommended that these be checked

after the first 2 hours of operation, initially, every 50 hours

and following removal for repair or replacement.

For all other torques refer to the various tractor parts

manuals for standard torque chart. See the Product Literature

section of this manual for ordering information.

For engine torque values, see engine service manual.

Tires

It is important that the tires have an equal amount of air

pressure. The recommended pressure are:

Front wheels. . . . . . . . . . . . 14-18 psi (96-124 KPa)

Rear wheels . . . . . . . . . . . .14-18 psi (96-124 KPa)

Solid fill tires are not recommended for Hustler turf

equipment. On any machine, with solid filled tires, the

warranty claim will be denied.

Lubrication

Engine Oil . . . . . . . . . . . . . . . See Chart below

Transmission Oil . . . . . . . . . . ISO VG 46

Grease . . . . . . . . . . . . . . . . . . SAE multi-purpose grease

Lubrication fittings

NOTE: After every 50 hours of normal operation, apply a

good quality grease to the lubrication points listed below

(refer to the Recommended Lubricants chart). When operat-

ing under extremely dirty conditions, lubricate more fre-

quently than every 50 hours.

• Lift cylinder

• Front Lift arm

• Power Steering Cylinder

• Brake pedal shaft

• Differential Lock pedal shaft

To lubricate these points:

1. Wipe away all old grease and dirt from the lubrication

fittings to prevent dirt or foreign material from

entering as new grease is applied.

2. Use a high pressure grease gun to force in the new

grease. Apply pressure until clean grease oozes from

each lubrication point.

3. Wipe away any excess grease.

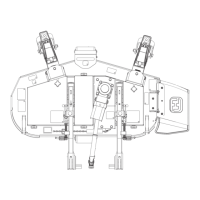

Service access

Opening the hood

WARNING: To avoid personal injury from contact

with moving parts:

Never open the hood and seat while the engine is

running.

Do not touch the muffler or exhaust pipe while they

are hot; severe burns could result.

Unlock the hood latch. Raise the hood using the hood

handle. Figure 4-1

Close the hood and clamp the hood latch.

Opening the seat platform

Pull out on the seat release knob and pivot the seat platform

forward. Figure 4-2

Electrical system

The electrical system is a 12-volt DC system with negative

ground.

The recommended battery size is a BCI group 35, 12-volt

battery with a minimum cold cranking ability of 490 amps at

-18°C (0°F). A maintenance-free battery is recommended.

Otherwise, follow battery manufacturer’s maintenance,

safety, storing and charging specifications. Refer to

Maintenance Locator Chart found elsewhere in this manual.

Recommended oils

Ambient Temperature Recommended oil

+ 40° — 120°F (+4.4° — 48.9°C) SAE 30W

+ 10° — 120°F (+12.2° — 48.9°C) SAE 15W-40

– 10° — 120°F (-23.3° — 48.9°C) SAE 10W-30

– 20° — 60°F (-28.9° — -15.6°C) SAE 5W-30

NOTE: Engine originally shipped with 10W-30 oil.

Loading...

Loading...