REV A 3-10 606653

Seat Belt Maintenance

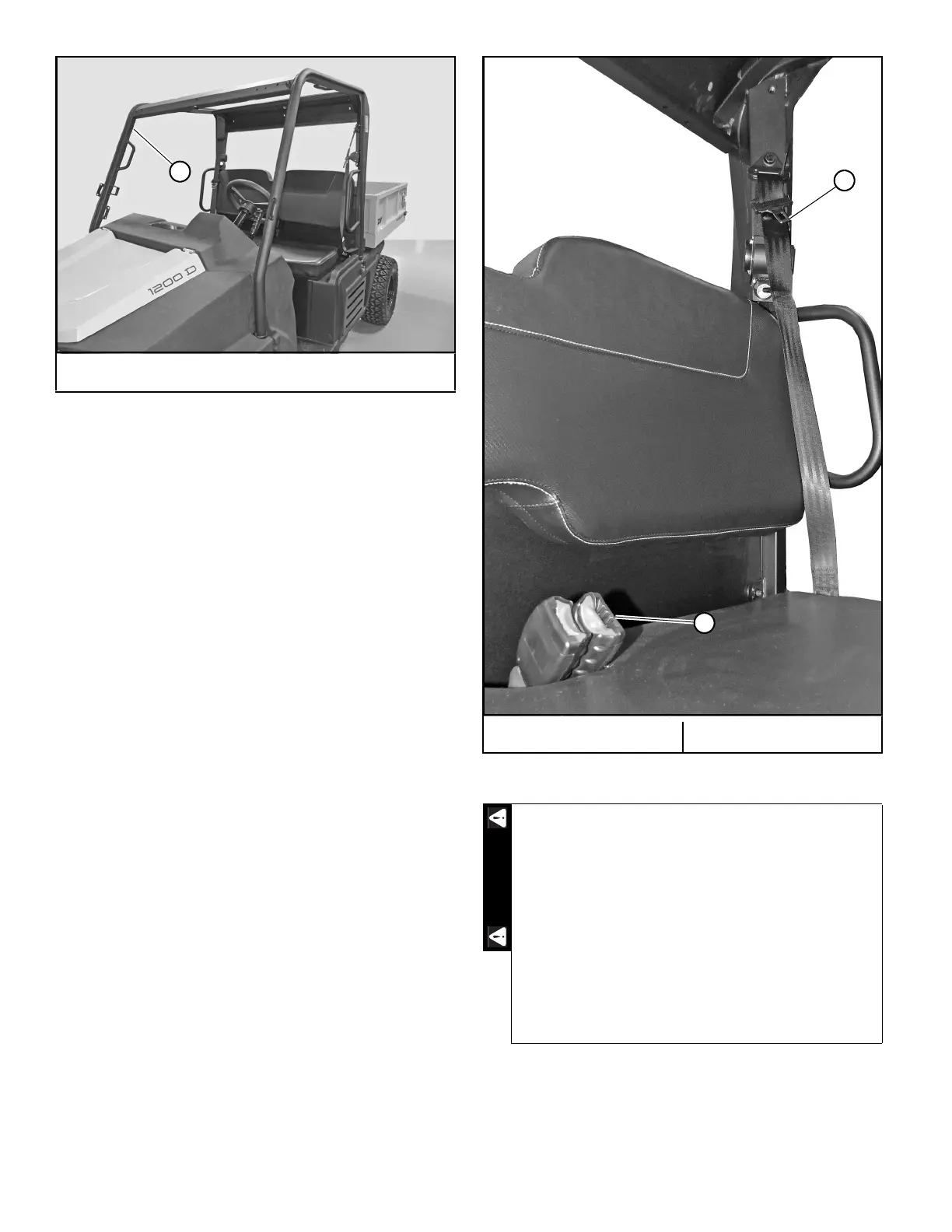

The seat belts used on the Hustler

®

MDV™ are a three point

emergency locking retractable type. Figure 3-18

Inspect the seat belt system (all seat, seat belt parts, and

seat platform) daily prior to operation for signs of any dam-

age. Replace any parts with signs of:

• cuts,

• fraying,

• extreme or unusual wear,

• significant discoloration due to UV exposure,

• dirt or stiffness,

• abrasion to the seat belt webbing,

• damage to the buckle, latch plate or hardware,

• any other problem.

Use soap and water to clean the seat belt. Do not use car-

bon tetrachloride, naphtha, or other chemical cleaning

agents, as these will weaken the webbing. For the same rea-

son, do not bleach or dye the webbing. Replace the seat belt

if worn or damaged.

Possible Damage to Occupant Protective Structure

If the unit has rolled over or the occupant protective struc-

ture has been in some other type of accident (such as hitting

an overhead object during transport), replace the occupant

protective structure to retain the best protection.

Following an accident, check the occupant protective

structure, the operator’s seat, the seat belt, seat belt mount-

ings and seat platform for possible damage. Before operat-

ing the vehicle, replace all damaged parts.

IMPORTANT: Do not attempt to weld or straighten the

OPS.

OPS Inspection

Inspect the OPS after the first 20 hours of operation. Fol-

lowing the initial inspection, check the OPS after every 500

hours of operation or every six months, whichever comes

first.

A. Occupant Protective Structure

Figure 3-17

A. Seat belt B. Seat belt latch

Figure 3-18

The occupant protective structure’s protective

capability may be impaired by structural damage,

overturn or alteration. Do not remove or alter any

of the occupant protective structure parts. Do not

attempt to weld, drill, grind, cut or straighten the

occupant protective structure. Failure to adhere to

these instructions could result in severe injury or

death.

If the occupant protective structure is replaced,

make sure to use the new hardware supplied with

the replacement OPS and apply the recommended

torque values to the attaching bolts.

Loading...

Loading...