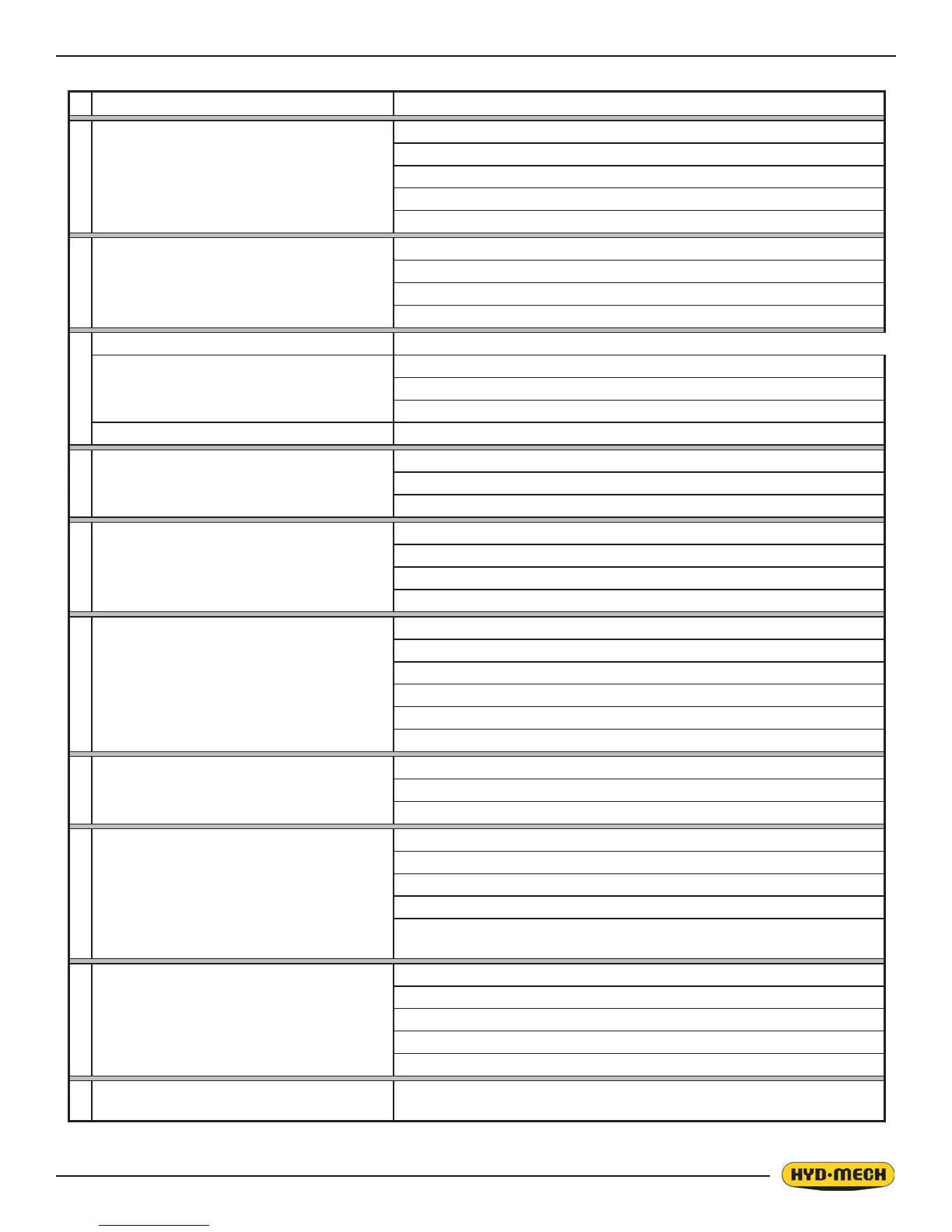

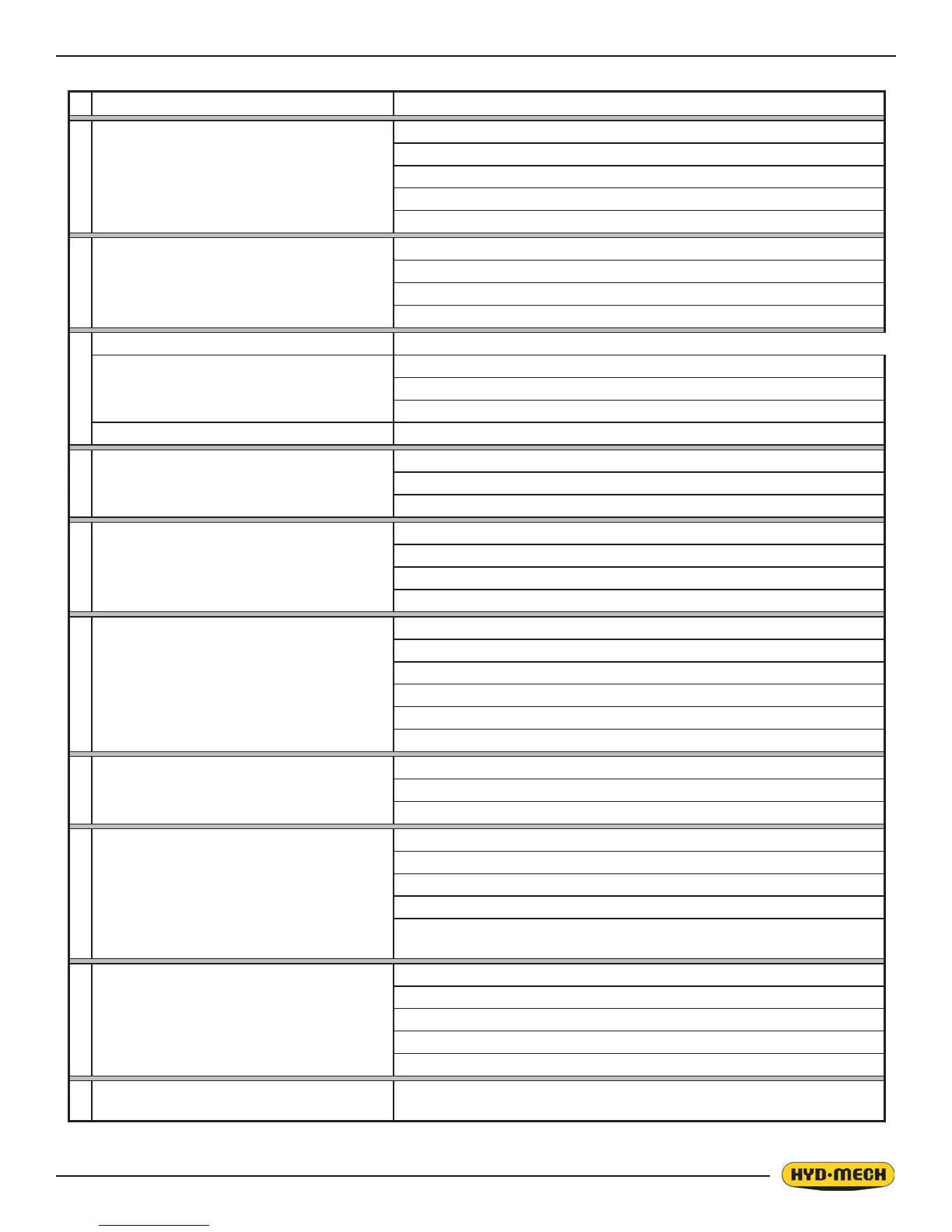

3.7

#PROBLEM PROBLEM CAUSE

1 Cutting out of square vertically.

Carbide guide adjustment incorrect (adjust).

Feed rate excessive (reduce).

Blade worn (replace).

Guide arms too far apart.

Blade pitch incorrect .

2 Cutting out of square horizontally.

Angle not set correctly (adjust).

Stock not square in vise. (reset material)

Angle pointer out of adjustment.

Stock is not secure in the vise. (reset vise)

3

Head cylinder creeps:

In Hold

Cylinder cup seal defective (replace).

3 position valve defective (replace).

Hydraulic hose leaking.

In Feed Position Loosen jam nut and readjust pointer with feed rate at zero.

4Blade tracking incorrect.

Improper tension (adjust).

Tracking needs adjustment.

Wheel is worn or in poor condition.

5Blade stalls in cut.

More tension needed.

Excessive feed rate (reduce).

Blade pitch incorrect.

Carbide guides overtightened.

6Blade vibrating excessively.

Blade speed too fast.

More Blade tension needed.

Guide arms too far apart.

Feed rate too slow (increase).

Carbide guides worn or loose (adjust or replace).

127(1HZEODGHVWHQGWRYLEUDWHXQWLOWKH\DUH³EURNHQLQ´

7 Excessive blade breakage

Excessive blade tension (reduce).

Excessive feed rate (reduce).

Top guide(s) damaged (replace).

8 1RFRRODQWÀRZ

No coolant (add).

Check coolant ports for blockage.

Line blockage (blow out lines with compressed air).

Coolant pump inoperable (replace).

Coolant pump has lost its prime, Loosen screws, sink pump in coolant.

:KHQFRRODQWVWDUWVÀRZLQJWLJKWHQVFUHZV

9Blade will not start.

Lift head off limit switch.

Control fuse blown.

Push reset button.

If present, Check safety door interlock switches.

9)'HUURU¿QGFDXVHUHVROYHDQGWKHQUHVHW237,21

10

Machine stops before cut is completed or

runs on after cut is completed.

Adjust head down limit switch bolt.

TROUBLE SHOOTING

Loading...

Loading...