地址:深圳市南山区中山园路

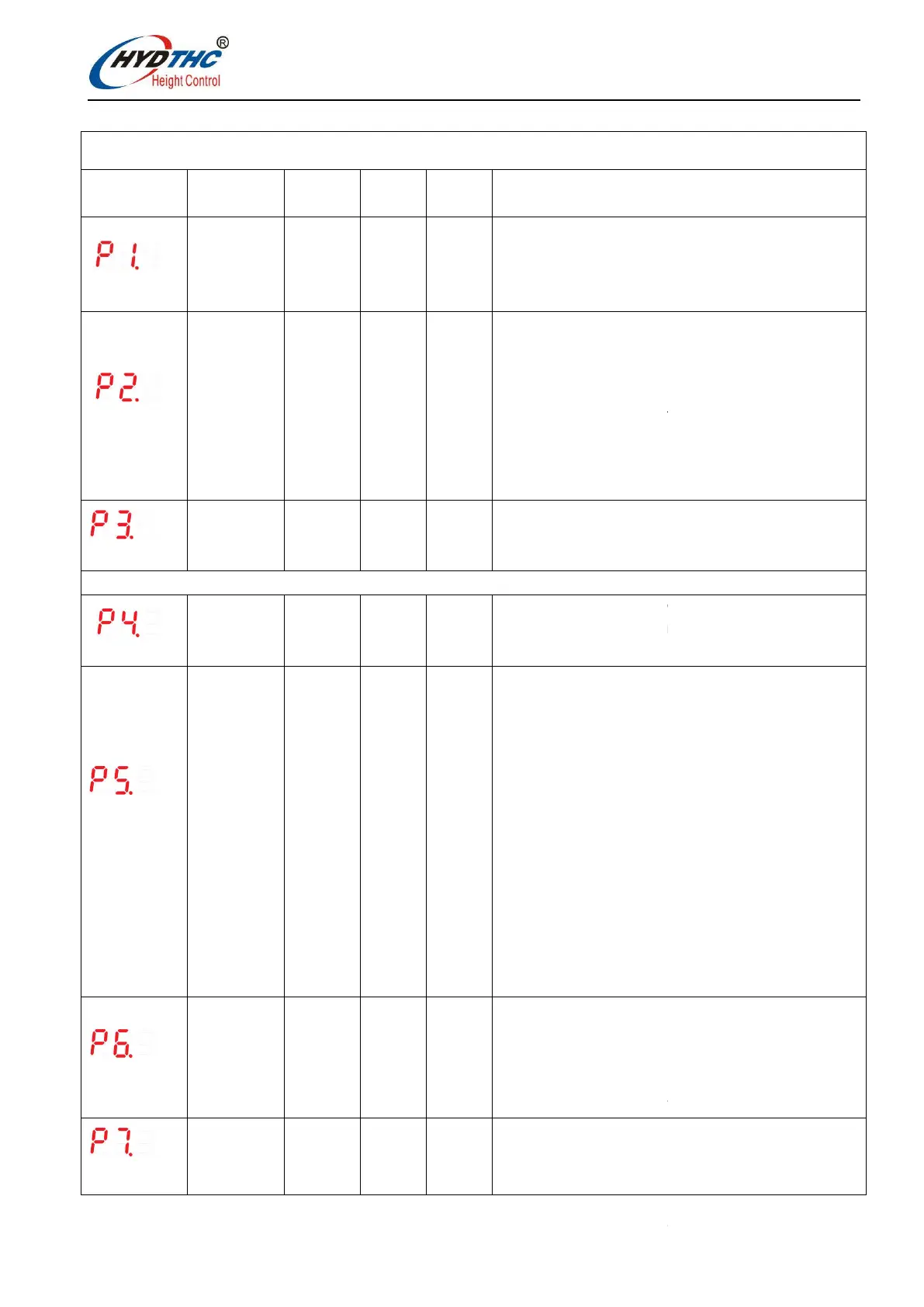

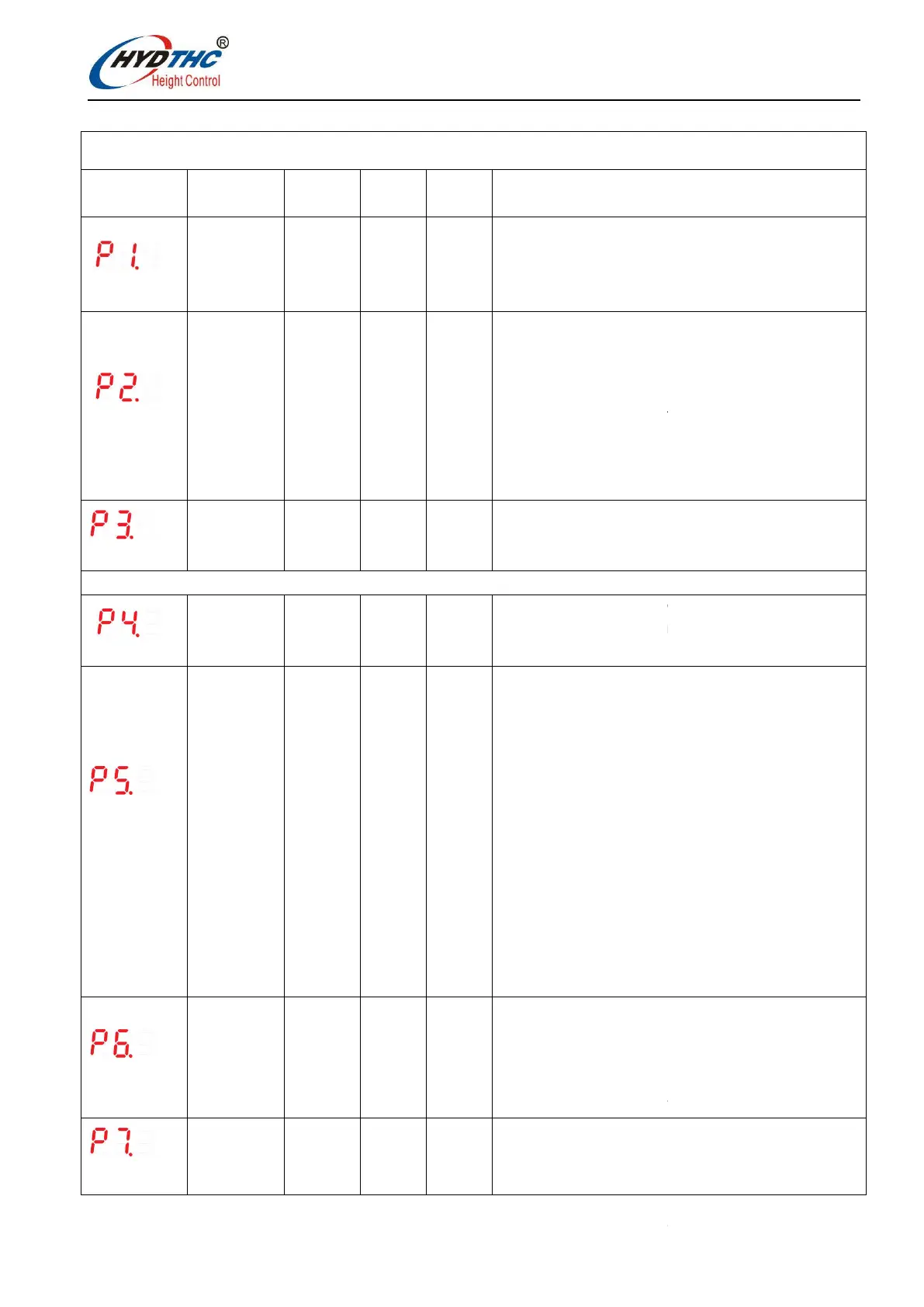

2.4.1、 Parameters details

Parameter

No

Parameter

Name

value

ARC

setting

130

Piercing

time

1

IHS height

0.4

dynamic

pierce

height

0

ARC

sampling

logic

0

Limit logic 0

Corner

signal logic

0

号 E4-6C(TCL 国际 E 城) TEL:755-

-14-

Unit Range

V 50~25

0

Setting a

rc voltage mode effective. Set

arc voltage before cutting, it can be adjusted by

“UP” or “DOWN”to change the setting arc voltage

during cutting.

10mS

00~60

When THC sends the

arc

then will delay the lead in arc voltage to THC,

thus it will

THC.

This parameter is also for dynastic pierce setting.

It’s set via the time of

the

as if it needs 3s for the Arc start process, then it

should be set to 30.

10mS

05~99

This IHS height can be g

the operation panel. It r

torch lifter.

10mS

00~99

This height

is for the plasma arc piercing

to protect the torch consumables.

0,1

1、 When set “0”,

the setting arc voltage by “P1”

set as

for the cutting height during auto work.

2、 when set “1”,

via the CNC’s corner signal,

when the THC is opened the AUTO function,

and take the actual arc voltage as the cutting

arc voltage during auto work. In this mode, it’s

required the CNC with high speed up to the

setting speed to open the auto mode, this is

the at the IHS height during cutting, it can be

used for bevel cutting.

During the cutting, it could be adjust the “UP”

and “DOWN” to change the arc voltage

sample, the cutting height won’t be changed

during the whole cutting work until loose Arc.

0,1 0:

closed.

When the connection is not match to the “P6”

parameter’s setting, then the UP_limit and

Down_limit LED light will be turned on.

0,1 0:corner logic

open auto

Note:This

:755-26729960

rc voltage mode effective. Set

the setting

arc voltage before cutting, it can be adjusted by

“UP” or “DOWN”to change the setting arc voltage

start signal to plasma,

then will delay the lead in arc voltage to THC,

has the anti

-interference function to

This parameter is also for dynastic pierce setting.

the

Arc start to Arc ok. Such

as if it needs 3s for the Arc start process, then it

ot from the IHS test on

the operation panel. It r

elates to the speed of the

is for the plasma arc piercing

height,

to protect the torch consumables.

the setting arc voltage by “P1”

for the cutting height during auto work.

via the CNC’s corner signal,

when the THC is opened the AUTO function,

and take the actual arc voltage as the cutting

arc voltage during auto work. In this mode, it’s

required the CNC with high speed up to the

setting speed to open the auto mode, this is

the at the IHS height during cutting, it can be

used for bevel cutting.

During the cutting, it could be adjust the “UP”

and “DOWN” to change the arc voltage

sample, the cutting height won’t be changed

during the whole cutting work until loose Arc.

;1: limit Normally

When the connection is not match to the “P6”

parameter’s setting, then the UP_limit and

Down_limit LED light will be turned on.

; 1: corner logic

be matched with CNC

Loading...

Loading...