12 Field Service Bulletin

HyPro2000 — HT2000 TORCH UPGRADE

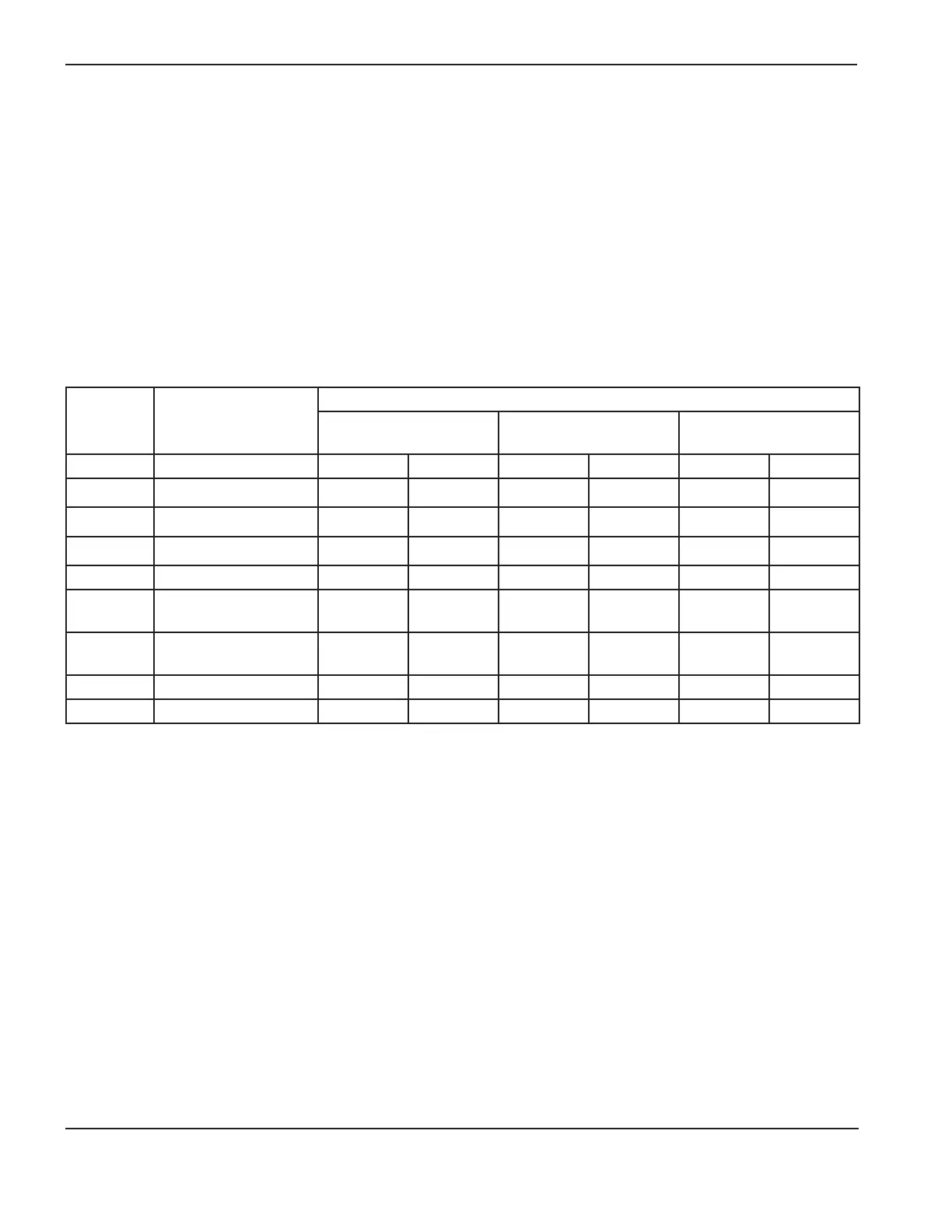

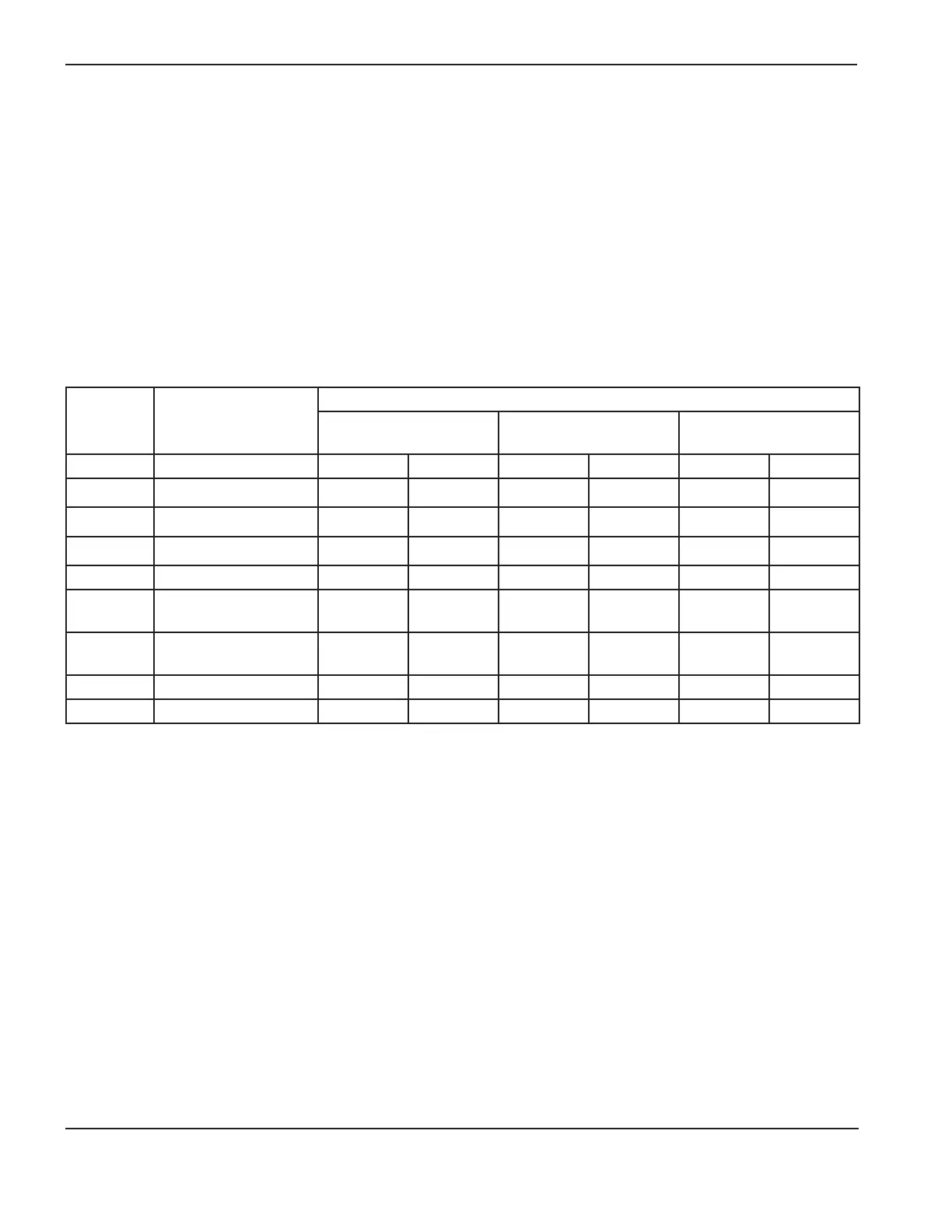

14. Verify gas pressures.

a. Turn on the power to the system and turn on the gas supplies.

b. Adjust the gas console settings for the chosen process using the cut charts in this document.

c. Verify the gas pressure reading on the gauge between the plasma gas line and the off-valve assembly with

the table below.

Note: Recommended incoming gas (supply gas) pressures are 120 psi for oxygen and nitrogen and 90 psi for air.

If the incoming gas pressure are not set correctly the back pressure reading will also

be incorrect.

15. Verify that there are no leaks at any of the connections.

16. Remove the pressure gauge that was installed in step 12 and the installation is complete.

Current Process

Test pressures

Preflow pressure

(at the off-valve)

Cutflow pressure

(at the off-valve)

Pressure while cutting

(at the off-valve)

Amps Gases psi bar psi bar psi bar

50

Air/Air

49.2 3.4 31.3 2.2 63.2 4.4

50

O

2

/Air

54.2 4.4 24.3 1.7 71 4.9

130

O

2

/Air

37.5 2.6 18.4 1.3 62.8 4.3

130 Air/Air 27 1.8 50 3.4 62.5 4.3

200

O

2

/Air

(copper electrode)

27 1.8 49 3.4 69 4.8

200

O

2

/Air

(SilverPlus electrode)

32 2.2 54 3.7 75 5.1

200 Air/Air 26 1.8 36 2.5 52 3.6

200 N

2

/Air 38.3 2.6 48.6 3.4 63.4 4.4

Loading...

Loading...