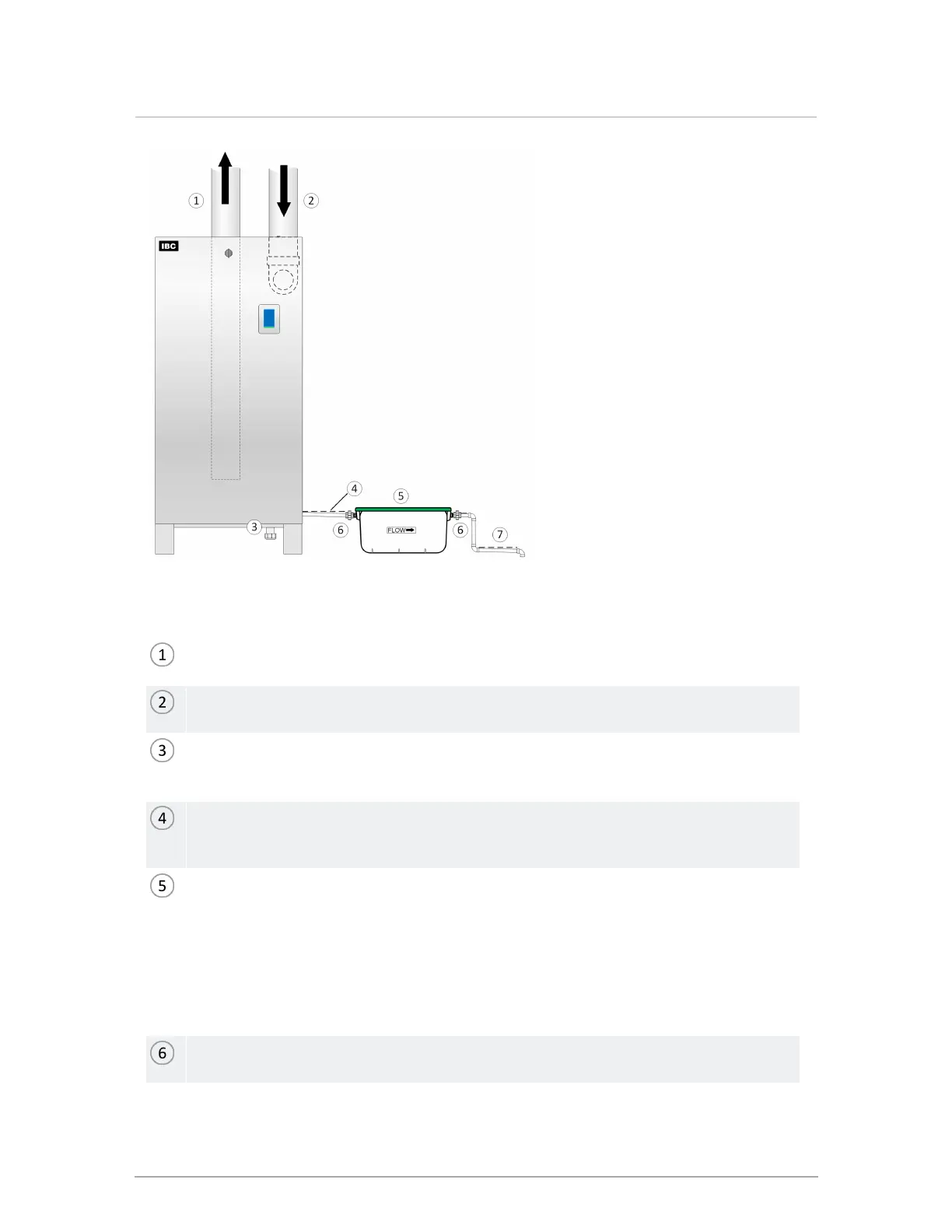

Flue gas exhaust (connection at rear of boiler): condensate, and potentially rain water, flow

back from the venting system.

Air intake piping: Warning - Risk of damage to appliance. Ensure rain water is prevented

from entering.

Free flow of condensate from venting systems and the pressure vessel must be maintained

at all times. Trap and condensate drain piping must be accessible to allow regular

inspection and cleaning.

Condensate water line: Warning - Risk of damage to appliance. All condensate discharge

lines, including neutralization tank inlet, must be at a lower elevation than the condensate

water line of the appliance.

Condensate neutralizer: Drain materials subject to corrosion must be protected by acid

neutralization. Warning - Risk of injury. Tank fluid can be highly acidic. Do not use hands

to stir material. Refer to the neutralization instructions of the manufacturer. Access to the

discharge, before the drain, is necessary for proper maintenance in order to check the

effectiveness of the neutralizing agent. A simple pH test should be performed annually to

ensure neutralizing agent is still effective. If the pH falls below 6.5 the neutralizing material

should be replaced. The agent (limestone chips with a minimum calcium carbonate content

of 85%) can be purchased from a local supplier.

1" FPT inlet and outlet. Unions for ease of maintenance (ships with shown model NT-25,

IBC part 180-048).

Loading...

Loading...