4-3

MAINTENANCE

SFT 199 TANKLESS WATER HEATER

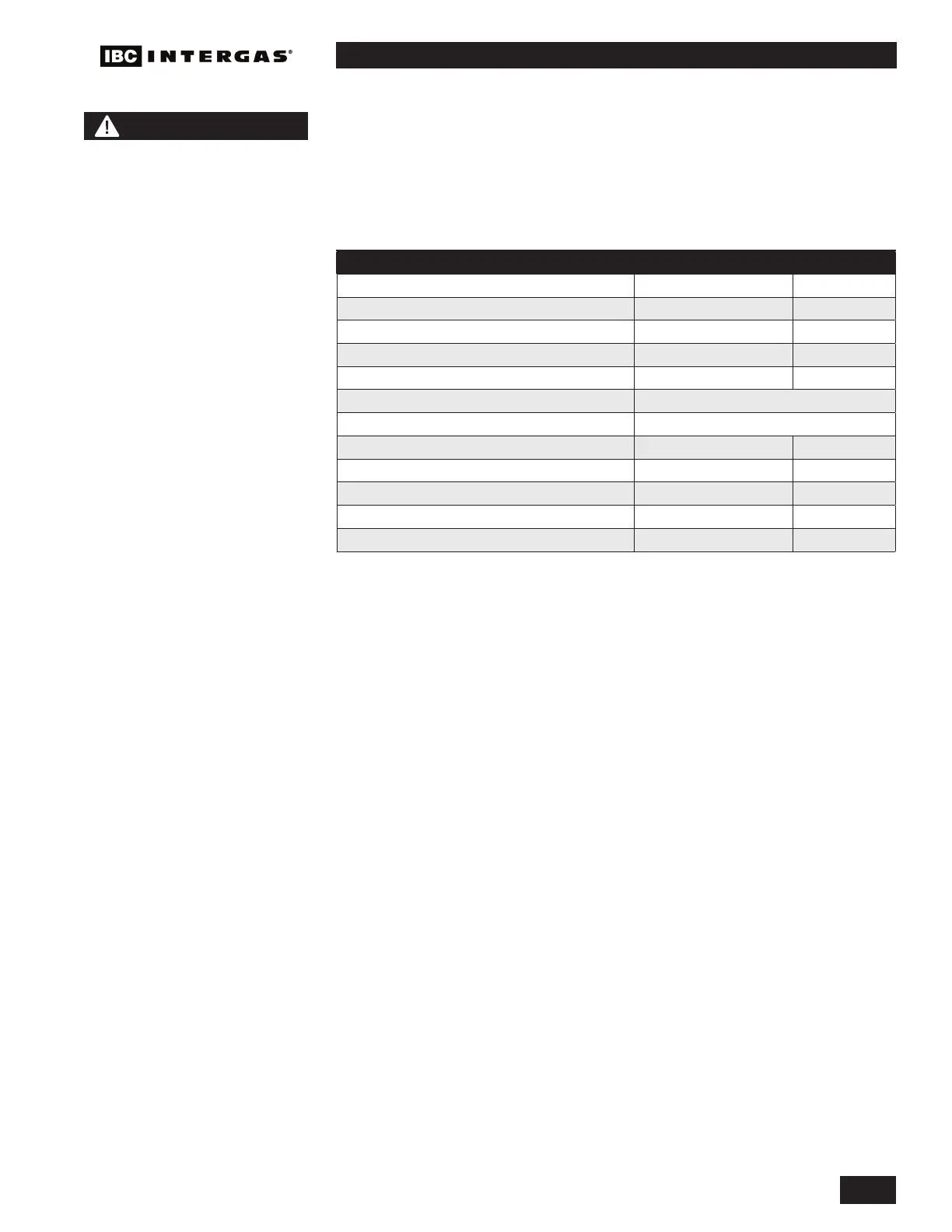

4.1.11 Domestic Hot Water System

Quality of the domestic cold water is very important to the longevity of the unit.

The recommended pH of the domestic water is between 6.5 and 8.5. The internal

domestic water heat exchanger tubing and the ow sensor is subject to fouling if

exposed to hard water (over 1.68 grains of hardness) or has a TDS of 500mg/L or

higher. See Table 13.

DESCRIPTION MAX MIN

Water Pressure 150 psi 40 psi

Programmable water temperature 149°F (65°C) 104°F (40°C)

Minimum Flow Rate to Activate DHW Sensor N/A 0.5 GPM

Acceptable pH range 8.5 pH 6.5 pH

Total Dissolved Solids 500 mg/L

Total Hardness 200 mg/L 11.68 gr/gal

Aluminum 0.05 to 0.2 mg/L

Chlorides 250 mg/L

Copper 1.0 mg/L

Iron 0.3 mg/L

Manganese 0.05 mg/L

Zinc 5 mg/L

Table 13: Domestic Water Quality Guidelines

4.1.12 Fan and gas valve removal instructions

1. Turn off the power and the gas supply to the unit.

2. Remove the front cover, and allow the unit to cool down.

3. Disconnect the electrical plug attached to the fan.

4. Loosen the union nut at the top of the gas valve. Carefully remove the ori ce

and O-ring, and keep in a safe place for re-installation later. Ensure you protect

the gas valve outlet from dust and debris.

5.

Remove the 2 hex nuts connecting the fan to the burner housing, and carefully

remove the fan. You will nd a gasket attached to the fan outlet as well as an

internal check valve. Keep these items in a safe place for re-installation.

6. If the removed fan is to be re-installed, ensure the fan and venturi are clean

and dust free.

4.1.13 Fan and gas valve re-assembly instructions

1. Place the fan gasket on the outlet of the fan housing. The gasket has 2 locator

pins to ensure the gasket does not move during installation.

2. Place the check valve on the fan gasket, and attach the fan to the burner

housing and install the 2 hex nuts. Tighten the 2 hex nuts with a wrench.

3. Insert the ori ce and O-ring between the gas valve outlet and the gas line to

the fan. Tighten the gas valve union nut with a wrench. Ensure that the gas

valve inlet (lower) nut is tight.

CAUTION

Before testing the relief valve,

make certain the discharge

pipe is properly connected to

the valve outlet, and arranged

to contain and safely dispose

of equipment discharge.

Loading...

Loading...