3-3

STARTUP AND COMMISSIONING

VFC 15-150 - VFC 45-225 MODULATING GAS BOILERS

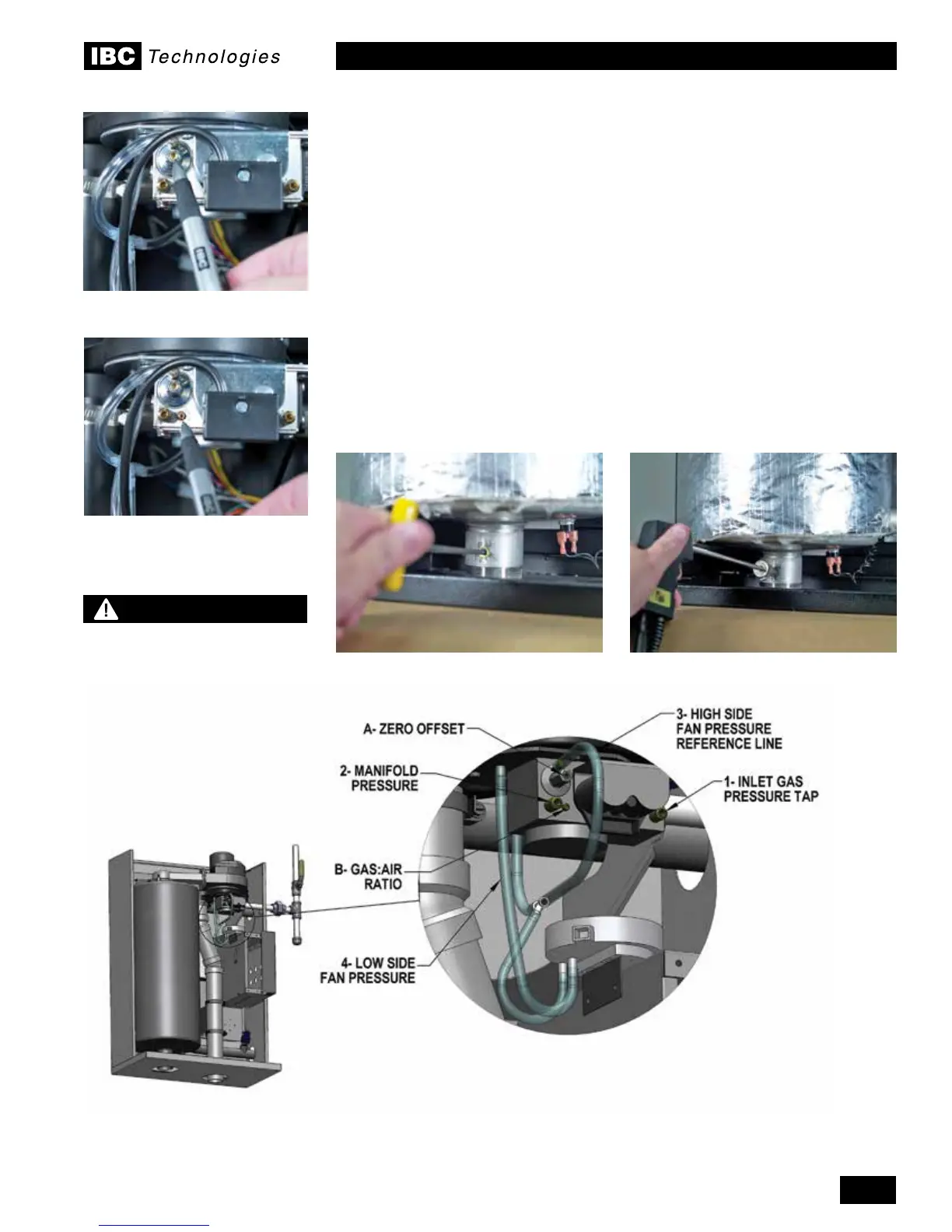

4. Withacombustionanalyzerprobeintheuegastestport,turntheGas:Air

Ratio Adjustment screw (see Figure 31, “B”) to achieve 28% excess air

(corresponding CO2 values are 9.2% for natural gas and 10.4% for propane).

Thisscrewoffersveryneadjustment,andmayrequireseveralturns.

NOTE:Thisscrewhassignicantbacklash.Whenchangingdirectionofturn,

it may take up to a full turn before any change is indicated on the analyzer

reading.Clockthegasmetertoconrmfullmaximumratingplateinput.

5. Toconrmoradjusttheminimumrelevelsettings,Re-denetheloadas

“ManualControl”.UseHeatOutputin“CongureLoadx”tocontroltheoutput

as needed.

6. Attheminimumringrate,adjustthezero-offsetscrew(see Figure 31, “A”)

to obtain 28% excess air. It may be necessary to reduce the output in stages

if this adjustment has been tampered with.

7. Turnboileroffbyremovingthecallforheat(usetheHeatLoadConguration

screen to turn load to off if no other ready means available), then remove the

manometer connections, and turn the centre-screw in the manifold pressure

test port 1 full turn clockwise. Ensure fully closed, but not over-tightened.

Figure 31: Gas Valve and Pressure Reference System

Zero-offset adjustment screw

Gas:Air ratio adjustment screw

Insertion of ue gas analyzer probeRemoval of ue gas test port plug

NOTE

Upon installation of this

boiler, you must use an

indelible marker on the rating

plate to mark an X in the box

associated with the fuel used.

Loading...

Loading...