Loading the

Tape

Punch

Place the roll of unpunch d tape on the turntable and

thread

as

shown in

Figure

3.

The

tape retainer (F )

must

be

rotated to the left

by

pushing back on

it

s

extended left edge. This moves the tape lever ( D )

forward to facilitate threading.

An

unwound sec

ti

on of

tape

is

then

thr

ad d

as

follows :

1.

Through tape guide (A).

2.

In

side tape guid (B

).

3.

In front of tape t nsion gUide (C

).

4.

In back of tape lever (D ).

5.

Betw en the punching mechanism and the

pun

ch

guide block (E ), which can b s en in front of

the tap

e.

6.

Between the guid

es

on the tape retainer (F ). \ \ i

th

the nd of the tap h ld

to

the I ft, the tapc

retainer (F ) is returned

to

normal position, which

causes

th

e pins on th feed roll

to

pi

erce through

th

e blank tape.

Th

e tape lever simultan ollsly r

e-

turns

to

normal position with

th

top guide above

the tap

e.

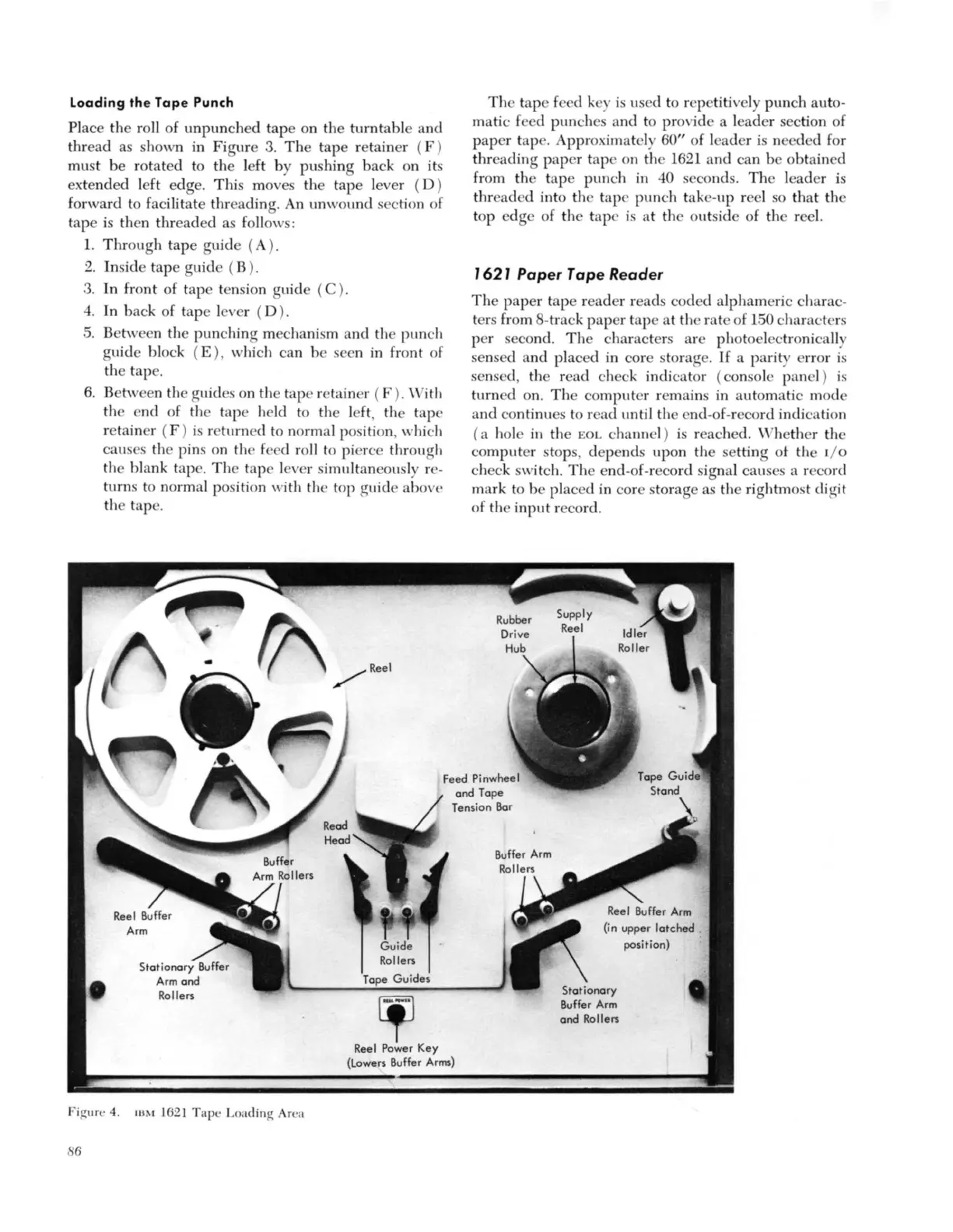

FigtITc

4.

IIJ~I

1621 T

ape

Loading Arca

86

The ta

pe

feed k

is

us

ed to rep titively punch auto-

matic fe d punches and

to

prOVid

e a lea

der

section of

paper

t

ap.

pproximately 60" of I

ader

is

n eded for

thr

eading paper tap on the 1621

and

can be obtain d

from the tap punch

in

40 seconds. The leader is

thr

eaded into the

tap

c punch take-up reel so

th

at the

top

edge

of the

tap

c

is

at the outside of the reel.

1621

Paper

Tape

Reader

The

paper

tape reader reads coded alphameric charac-

ters from 8-b'ack

pap

er tape

at

the rate of 150 characters

per second.

Th

characters ar photo lectronically

sensed and placed

in

core stora

a

.

If

a parity error is

sensed, the read check indicator (console pan I)

is

turn d on.

Th

e computer remains in automatic mode

and

continue

to

read until the nd-of-record indication

(a

hoI

in

the

EOL

channel)

is

reached. Whether the

comput

I'

stops, d pends upon the setting

ot

the I / O

check switch.

Th

end

-o

f-record signal causes a record

mark to be placed in cor storage

as

the rightmost digit

of th input record.

Loading...

Loading...