Loading the

Pap

er T

ap

e

Reader

Paper

t

ape

can

be

handled

in

two forms.

Th

e proc

e-

dures for loading each fonn vary slightl

y.

The

nam

es

of machine components us d in

th

following de 'crip-

tions of loading proce

dur

es

are

given in

Figur

4.

CENTER

ROLL

FEE

D

The

cent

1'1'0

11

feed Hminat

es

the nec s

it

y for

I'

wind-

ing

pap

er

tape

rolls which would

ex

pose the starting

end

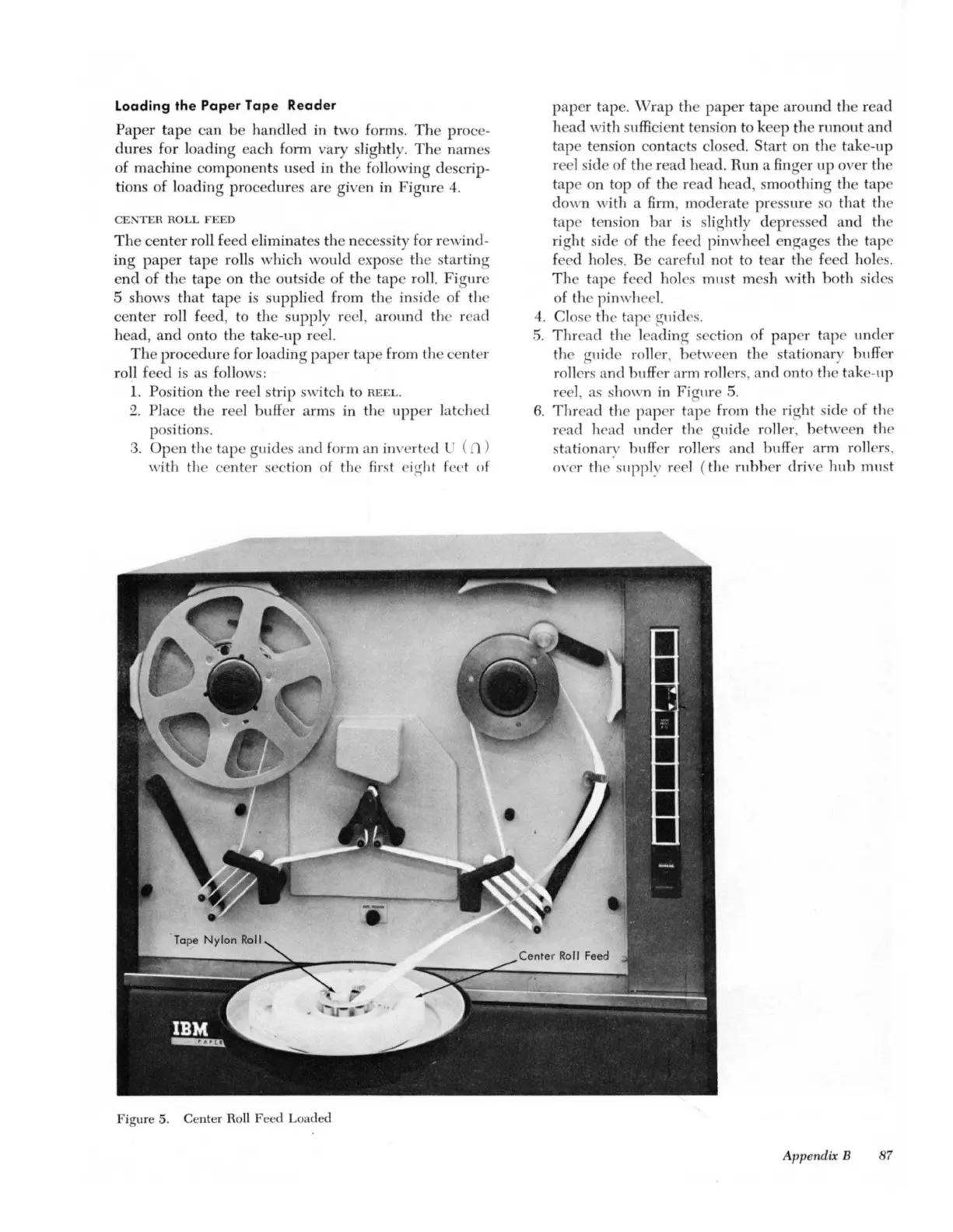

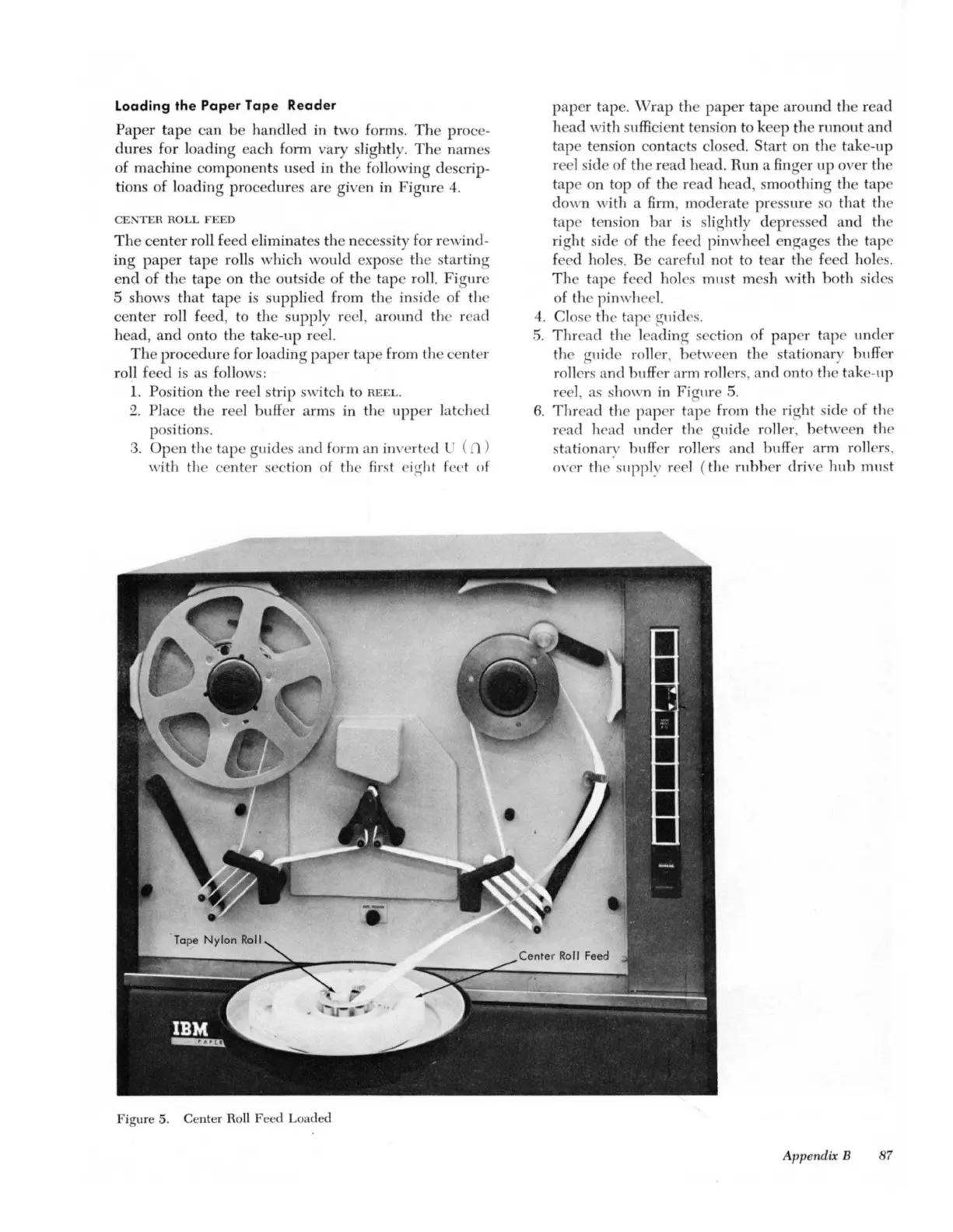

of the tape on the outsid of th tap roll. Figure

5 shows

that

tap

e is suppli d from the inside of the

center roll fe d, to the supply reel arou

nd

th

I'

- ad

he

ad

,

and

onto the take-up

I'

e

l.

Th

proc

dur

e for loading

pap

I'

tape from th center

roll fe d is as follows:

1.

Position the reel strip switch to R

EE

L.

2.

Pl

ace the reel buffer arms in th

upp

I'

latched

po ition

s.

3.

Op

n thc tape guid s and form an inve

rt

ed

with th c

nt

er ec

ti

on of th

fir

st eight F

e'

t of

Figure 5. Center Ro

ll

Feed Loaded

pap

er tap .

Wr

ap

the

paper

tap

e arou

nd

th read

head wi th suffici

nt

tension to keep the

runout

a

nd

tap

e tension co

nt

acts closed. Sta

rt

on the tak -up

r I sid of the r

ead

h ad.

Run

a

fin

ger

up

over the

tape on top of the

read

head, moothing the tape

down with a firm, mod

rat

e

pr

e sure so th

at

the

tap

e tension b

ar

is s

li

ghtly de

pr

sed

and

th

ri

g

ht

si

d of the feed pinwheel engages the t

ap

f d hoI

s.

Be careful not to tear the feed hoi

s.

Th

e tap feed hal s must mesh with

both

sid s

of the pinwl e

l.

4. Clos the tape guides.

5.

Thr

ead

th l ading s ction of

pap

er tape under

the guid roll r, between the stationary bu

ff

r

ro

ll

ers a

nd

buffer arm roll r

s,

and o

nt

o th tak

e-

up

reel, as shown

in

Figure 5.

6.

Thr

ead th

pap

er

tap

fr

om th

ri

g

ht

id

e of the

r ad h ad under the guide roller, b tw

ee

n th

stationarv buff r rollers and buffer arm rollers,

o r th . supply r el ( the

rubb

er drive

hub

must

App

endix B

87

Loading...

Loading...