be installed ), around the tape guide stan

d,

and

around the tape reel nylon roll.

7. Lower th idl r roller onto the supply r

I.

8. Lower the buffer arm gentl

y.

9.

Pr

ess

the reel power key. The buffer a

Tm

s should

swing down

to

a neutral po ition, apply

in

g tension

to the

pap

er tape.

NOT

E :

Th

e roll of

pap

er tape must be po itioned cen-

trall

y,

or evenl

y,

around the ce

nt

er rollers to

pr

event

ex

c

ess

ive vibration during readin

g.

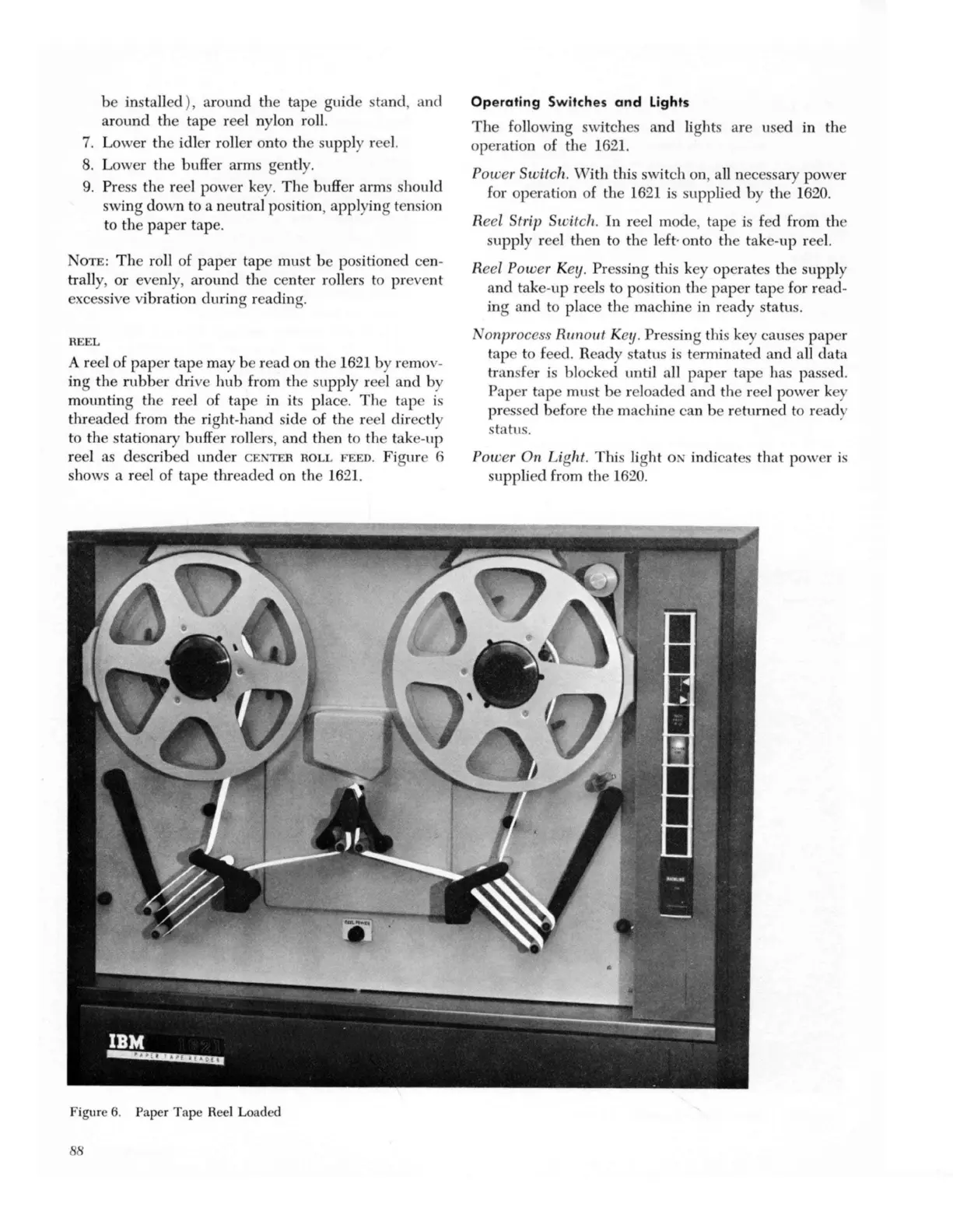

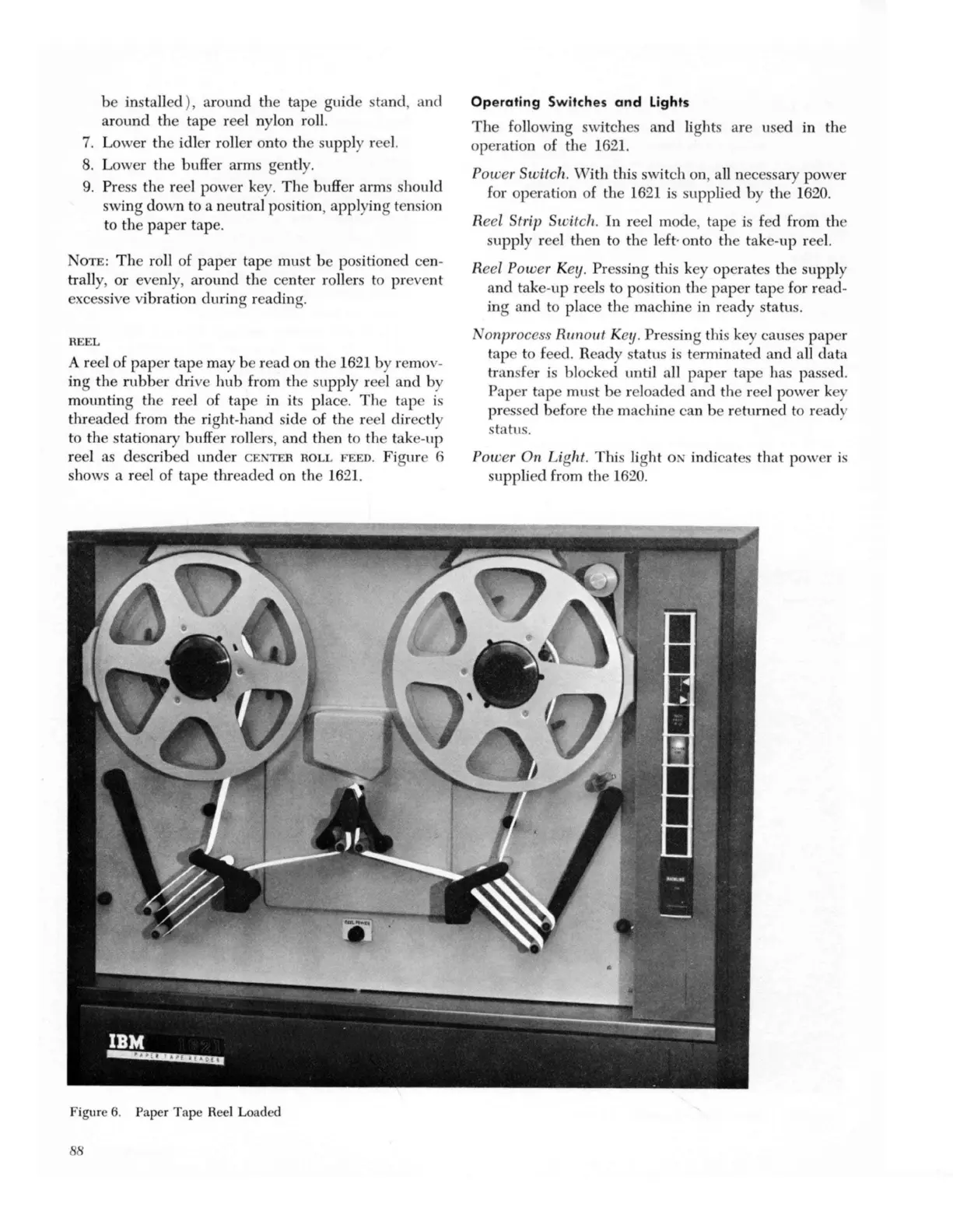

R

EE

L

A reel of

pap

er tape may be r ad on the

16

21 b remov-

ing the

rubb

er drive

hub

from the upply reel and by

mounting the re I of tap in

it

s place.

Th

e tap IS

threaded from the

ri

g

ht

-hand s

id

e of

th

e reel direc

tl

y

to

the stationary buffer roller

s,

and then to the tak

e-

up

reel as d

es

cribed under

CE

'

TE

R

ROLL

FEE

D. Figure 6

shows a reel of tape thread d on th

16

2

1.

Figure 6. Paper Tape Reel Loaded

88

Operat

ing Switches

and

Lights

Th

e

fo

llo

wi

ng switche a

nd

li

g

ht

s are used in the

operation of the

16

2

1.

P

owe.,.

Sw

it

ch. With this switch on a

ll

nec

ess

ary power

fo

r opera

ti

on of the

16

21 i ' upplied by the

16

20.

Reel Strip Sw i

tc

h.

In

reel mod

e,

tape is fed from the

supply reel then

to

the left· onto the tak -up ree

l.

Reel P

owe

r Key. Pr

ess

ing this key operate the supply

a

nd

take-up reels to p

os

ition the

pa

per tap for read-

in

g a

nd

to place the machine in ready statu .

on

rJ

rocess Runout Key. Pr

ess

ing this key causes

pap

er

tape to fe d. Ready status i terminated and a

ll

dat

a

tran

fe

r is block d until all paper tape h

as

pa se

d.

Paper tape must be reloaded and the reel power key

pr

essed before the machine can be r turned to read

status.

Po

we

r On L

ig

h

t.

This

li

g

ht

0 r indicat

es

that power i '

supplied from the

16

20.

Loading...

Loading...