Lowering the pump in the borehole with a protective strip may

damage the cable insulation. This may damage the pump or cause

electric shock to the operator.

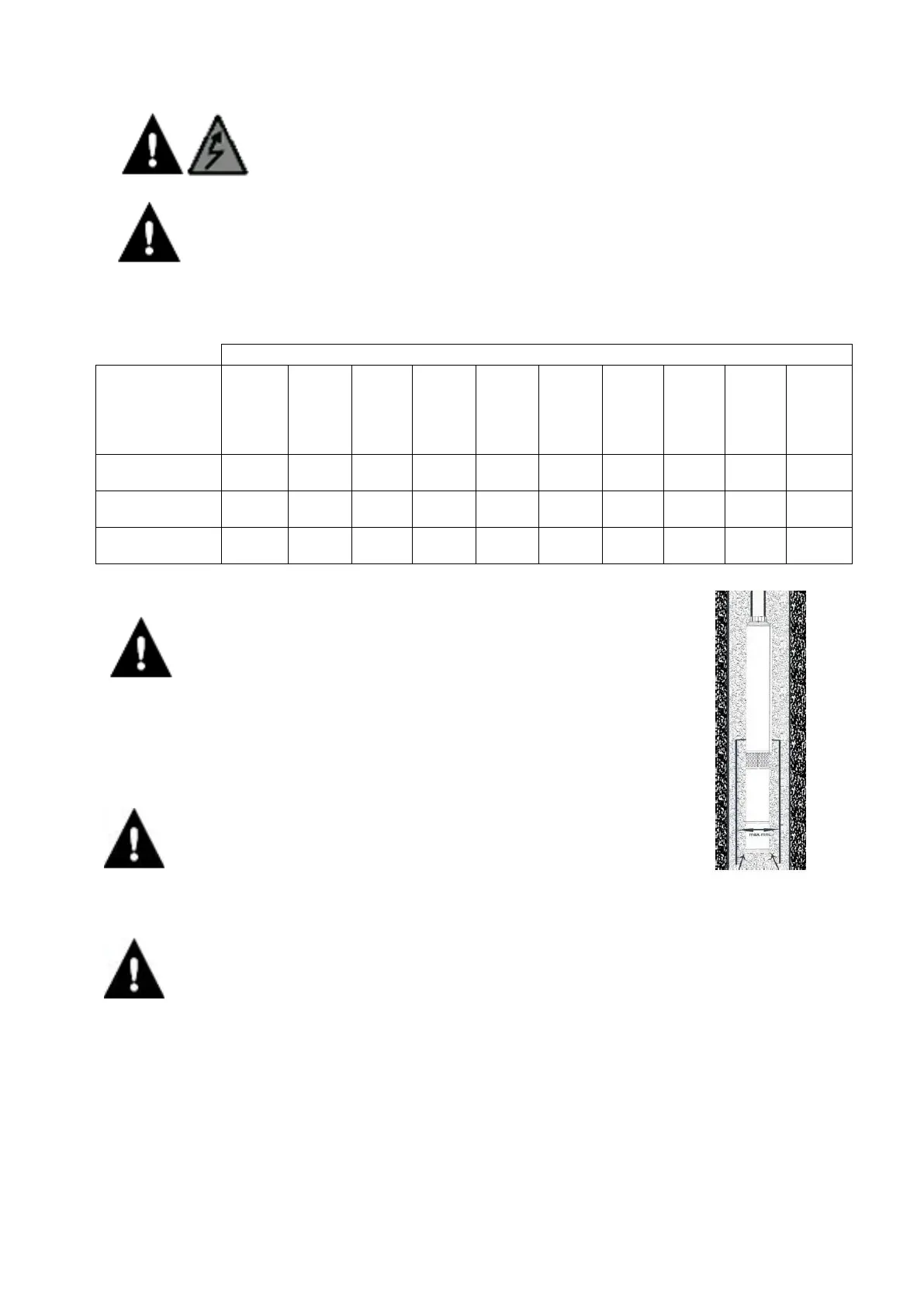

Since the motor needs cooling during operation, the diameter of the

borehole where the pump is working may not be greater than the value

given below in the table of diameters. The values are given in mm. These diameters

depend on the working

capacity of a given pump and dimension of pump.

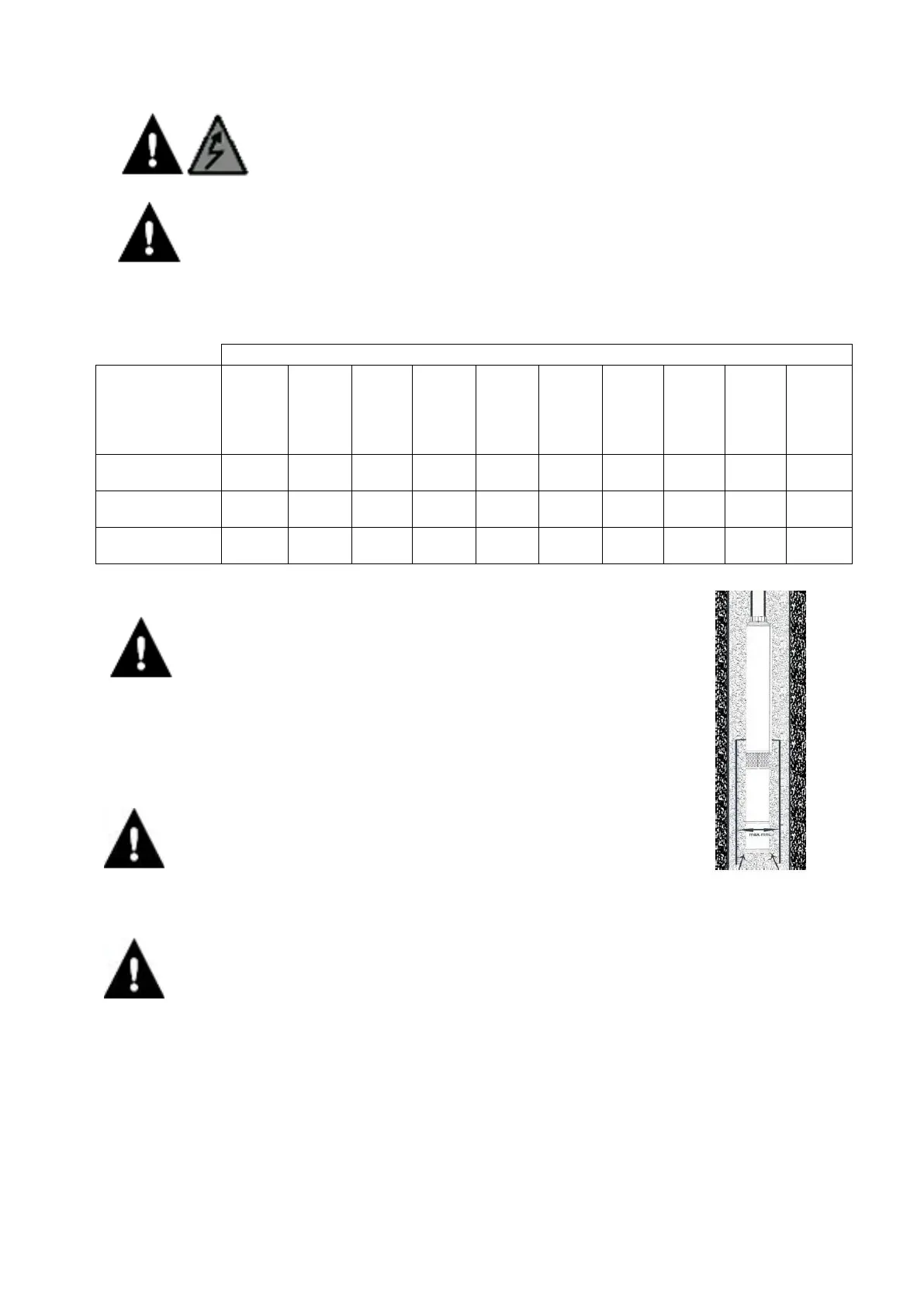

Using the pump in a well of a diameter greater than the

one given in the table might overheat and damage the

motor. If the diameter of the well where the pump is to be working is

greater than the diameter given in the table, the pump must be

installed in a special coat which enforces proper cooling. The

concept of the coat has been shown in the figure.

The pump must be installed above the filter of the well.

The minimal

distance between the upper edge of the last part of the filter

and the lower

edge of the motor may not be less than 30 cm.

The pump may not dry run, without water. Dry run damages the

equipment. In this case the repair may be performed only against payment.

To prevent potential dry run the pump must be installed at such depth so that the

lowest dynamic level of the water (water level established during continuous pumping

at free outflow) is at least 2 m above the liquid feed port of the pump.

If the efficiency of the well prevents such assembly (the well is not as efficient as the

pump) then choose an option from the following:

- install smaller pump

- install a valve for constant reduction of the flow on the delivery pipeline,

- install a safety device against dry run to control the level of water table and in

case of dry run to cut off the power supply to the unit.

Loading...

Loading...