English

14

71503816/0 - REV.04 01/2013

6. SERVICE INFORMATION

LL= flashing slowly

LV= flashing quickly

LA= alternate flashing

ON = steady light

1. Verify that the water supply valve is open, then plug in the

machine and switch on the main switch; the appliance starts-

up in automatic mode (fig.

g

) after having pressed the

ON/OFF start button (fig.

2@

).

2. Verify that the water reaches the tray, the float stops the

water before the overflow and that there are no leaks in the

system and in the water channels. The normal level of water

inside the tray is about 5/10 mm from the upper edge (fig.

k

).

The level of water can be adjusted by rotating the microfloat

or the water sensor on the slot on the relative support after

having loosened fastening screw 1 (fig.

k

). This adjustment

must be implemented after having disconnected the power

supply.

3. Verify that there is no abnormal vibration due to loose screws.

4.

Always stop the appliance before implementing any operations

to resolve water leaks, tighten screws, etc.

5. Verify an ice production cycle ensuring that the cubes are

conveyed into the container.

6. Verify that the container sensor functions properly: place an

ice cube on the bulb inside the container; the appliance

should stop within 1 minute and restart automatically shortly

after removing it.

7. Replace the cover previously removed.

THE FOLLOWING OPERATIONS MUST BE

IMPLEMENTED SOLELY BY OUR

QUALIFIED PERSONNEL

4. SIGNALS

5.

OPERATING PROBLEMS

• If the condenser overheats

The machine stops and only the air/water condensation remains in operation. The machine automatically restarts when the tem-

perature returns to below the limits set. Only after three consecutive alarms within a period of 5 hours, the machine turns off and

stays off.

• Freezing cycle too long

In the case of three consecutive alarms within 5 hours, the machine stops.

Calculation of the maximum time of the freezing cycle:

1

st

cycle = 50'

2

nd

cycle = duration of 1 cycle x 1.5.

If the 1st cycle lasted less than 7' the maximum time of the next cycle will be 50'.

• Defrosting too long

If the defrosting time is greater than 2 minutes and there are 2 consecutive failures within 5 hours, the machine stops.

• Freezing cycle less than 7 minutes

The electronics calculate the cycle time as too long at 50 minutes.

• Water loading too long

If the load time for the water is greater than 5' the machine stops in alarm. After a break of 120' the machine restarts automatically.

If water shortage is ongoing, the machine will attempt to restart every 120'.

Function Status

Led 1

Green

Led 2

Red

Notes

Machine ON ON OFF

Applicable to all

conditions that are

not in alarm/error

B

in temperature

sensor error

OFF LL

Temperature sensor

out of range.

Machine OFF

Condenser

temperature

sensor error

OFF LL

Temperature sensor

out of range.

The machine

continuous to run

Error cold cycle too

long or defrosting

too long

ON ON Machine OFF

Condenser

overheating error

OFF ON Machine OFF

No water error LL ON

The signal is triggered

after attempting to restart

Maintenance

warning

LA LA

The pre-set number of

operating

hours has been

reached. The machines

continous to run

Wash / clean LV LV

Signalled during the wash

routine

Start stand-by LV OFF

Waits to start after

switch-o

English

15

71503816/0 - REV.0401/2013

7. CLEANING AND MAINTENANCE

• Use a cloth dampened with a specific chlorine-free product

for stainless steel to clean the structure.

Note: Disconnect the electrical power supply from the appliance

to perform maintenance and cleaning operations.

6.1 CLEANING THE AIR CONDENSER

• To make the most of your appliance in terms of efficiency

and durability, the air filter at the front of the machine must

be cleaned every week (fig.

2#

).

• The filter is removed by simply extracting it. Simply wash the

filter with a water jet of warm water and dry it before setting

it back in place.

Do not use brushes or blunt objects to clean the filter.

It is absolutely forbidden to operate the producer without

the air filter to prevent malfunctioning.

6.2 CLEANING THE WATER INLET FILTER

• Close the water shut-off valve of the appliance, disconnect

the water inlet pipe and remove the filter screen that is on

the water inlet electrovalve with a pair of pliers.

• Clean the screen with a water jet and reassemble it into its

place.

6.3 CLEANING THE CONTAINER

• Remove the ice from the container. Clean inside the con-

tainer with a sponge dampened with warm water and a lit-

tle sodium bicarbonate;

• rinse with clean water and dry carefully.

6.4 THE WASH AND SANITATION CYCLE

• The machine has been equipped with a “Self Cleaning” func-

tion in order to remedy the problems deriving from the hard-

ness of the supply water and therefore, the formation of

impurities on the components and parts that are in contact

with the water.

Thanks to the cleaning action of a specific product, which

comes in the form of powder in a sachet and a dosing bot-

tle, this function keeps the machine clean and sanitised from

limescale and deposits.

• To guarantee proper cleaning of the ice maker one recom-

mends carrying out the wash cycle at least 3-4 times a year,

according to the hardness of the water supply.

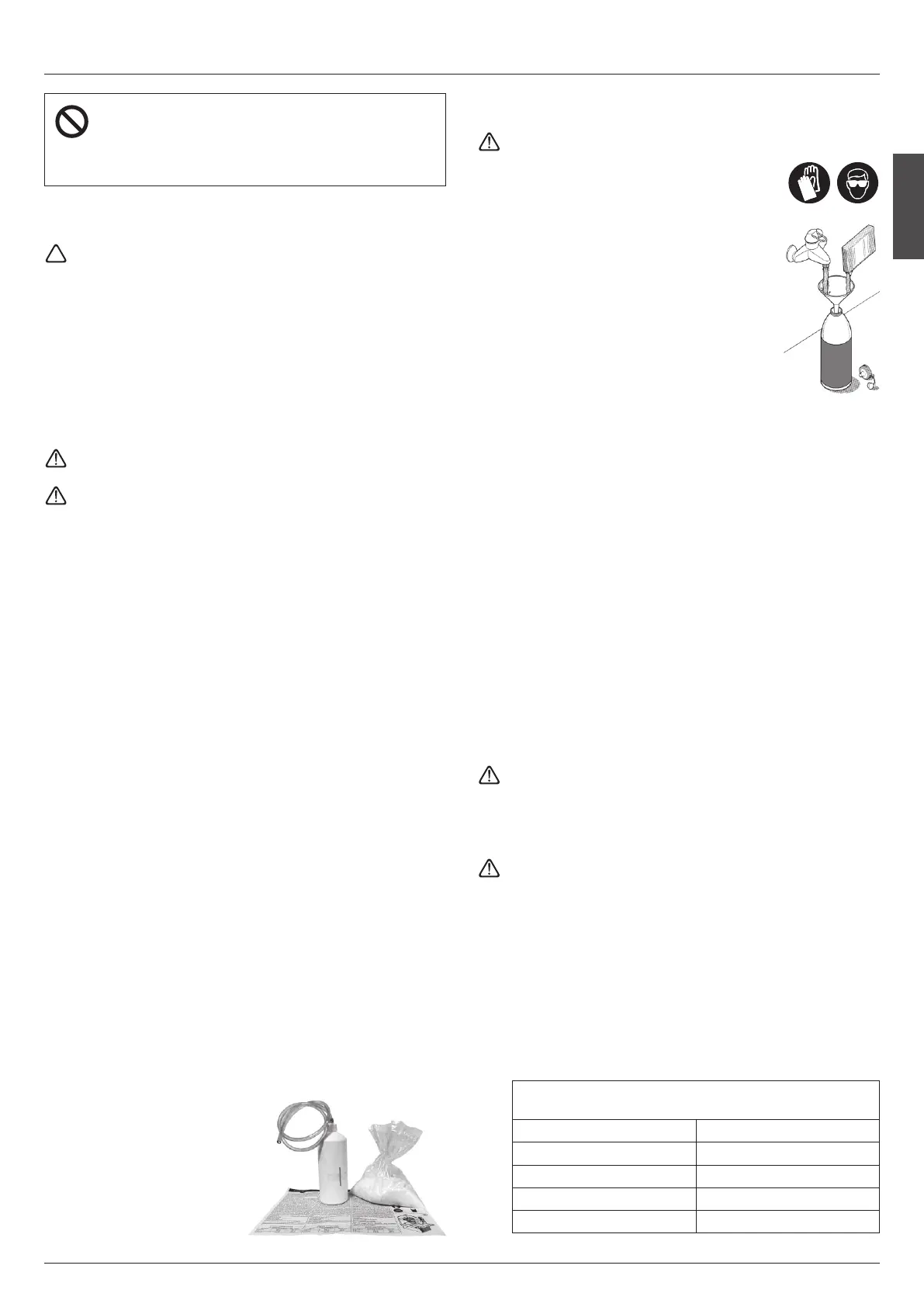

Cleaning kit (optional)

The kit is composed of a plas

tic bottle with rubber pipe,

one confection of acid citric 1

kg., and instructions for the

cleaning proc

edure.

6.5 IMPLEMENTING THE WASH AND SANITATION CYCLE

Adopt proper precautions when handling citric acid whilst

preparing the solution (water+ citric acid,

see the table). Wear protective gloves and

goggles.

• Turn the machine off.

• Remove all ice from the container.

• Using the specific product and the plastic

bottle, prepare the solution by dissolving

the powder in warm water (max. 40°C), ac-

cording to th

e quantities shown on the at-

tached table. Mix well whilst ensuring that

no lumps are formed.

• Switch the machine on by pressing the

ON/OFF button whilst keeping the RESET button pressed

(fig.

2@

). Press the RESET button using a pin of suitable di-

ameter to enter the appropriate hole.

• Both LEDs will flash quickly. Open the deposit hatch, wait for

the tray to go back into closing position. Insert the cannula

into the bottle throughout its length in the appropriate hole

(fig.

2$

) and drain all the previously prepared descaling mix-

ture, applying pressure with your hands on the bottle. Close

the hatch and repress the RESET button to start the WASH-

ING cycle.

• Once the wash cycle is started, LED flashing will slow down.

During the wash function, rinse the container thoroughly.

• The duration of the washing cycle is of approximately 3

hours.

• Once the descaling function has started it is not possible to

interrupt the washing cycle. In case of a power-cut, the ma-

chine resumes from where it had stopped.

• At the end of the washing and rinsing cycle the machine

restarts in the cold cycle.

For all extraordinary maintenance and/or repairs (me-

chanical, cooling and electrical parts) that require adjust-

ments and/or components to be replaced, always refer to

an authorised service centre.

If the appliance should not be used for long periods of

time:

- disable the machine

- remove all the ice from the container

- drain all the water

- thoroughly clean the machine

- leave the door of the container ajar

• After a long period of inactivity one recommends to perform

a cleaning/descaling cycle before commencing ice produc-

tion.

i

THE FOLLOWING OPERATIONS MUST BE

IMPLEMENTED SOLELY BY OUR

QUALIFIED PERSONNEL

Quantities of citric acid to be mixed with water

in the bottle to obtain the mixture

MODEL CITRIC ACID Q.TY

E21 - E25 200 gr.

E35 - E35L 250 gr.

E45 - E50 500 gr.

E60 - E75 - E90 500 gr.

Loading...

Loading...