English

16

71503816/0 - REV.04 01/2013

8. TECHNICAL SERVICE DATA

8.1 ELECTRONIC BOARD FUNCTIONS

• Ice level check with probe

• Condensing temperature check with probe (machine stop

with temperature > 70°C water version; > of 80°C air).

• Maintenance check. The maintenance alert can be pro-

grammed after a certain number of hours of functioning.

• Wash/cleaning cycle check to be carried out periodically with

manual control.

8.2 ELECTRONIC BOARD INPUTS AND OUTPUTS

• Condenser probe: with condenser temperature < 24°C, the

board makes the fan turn guaranteeing optimal condition of

condensation and machine yield.

• Resistance values of the temperature probes (deposit probe

and condenser probe) with reference to the room tempera-

ture:

• PCB MICROPROCESSOR RESET

Pressing the ON/OFF button.

8.3 OPERATION CHARACTERISTICS

• On the starting the machine goes into defrosting and dis-

charge the water pan.

• The production cycle start with two minutes of delay that

allow a correct balancing of the refrigeration system and

therefore a good output and a best production.

• During the machine operation, at the end of every defrost-

ing, the water load happens with 80 seconds of delay, this to

allow the evaporator subcooling.

• When the bin is fu

ll of ice, the probe comes in contact with

the ice and the electronic card stop the machine only on the

end of defrosting time. This to always have the cubes com-

pletely formed and at the same dimensions.

• Signalling of alarms for the models air and water version:

- condenser overheating : the machine goes to alarm and it

restart again automatically once that the cause has been re-

moved and / or the temperature has re-entered in the range

of established operation;

- error of not water feeding: in case of lack of water the ma-

chine automatically start again after 60 minutes from the

alarm reset.

8.4 WASHING CYCLE

Note:

• Time of complete washing cycle: 3 hours

• The washing / cleaning cycle is formed of: 90 minutes of

washing plus 5 rinsing of 15 minutes each.

• At the end of the washing cycle the machine automatically

start again in cold cycle.

• The water level sensor inside the basin works with waters

with conductivity between 20 and 1000 micro-siemens per

centimetre.

• The water level sensor can be replaced by a microoat. Con-

nection is the same for both.

• If the machine is supplied with softened water (deminer-

alised), oat kit installation is recommended (g.

k

)

In case of incorrect startup cycle (by the user) to exit the

cycle you must press the reset button for more than 10 se-

conds during the wash. (Not active during rinse cycle).

THE FOLLOWING OPERATIONS MUST BE

IMPLEMENTED SOLELY BY OUR

QUALIFIED PERSONNEL

Temperature °C Sensor resistance Ohm

20 2762,034556

25 2200,000000

30 1765,531939

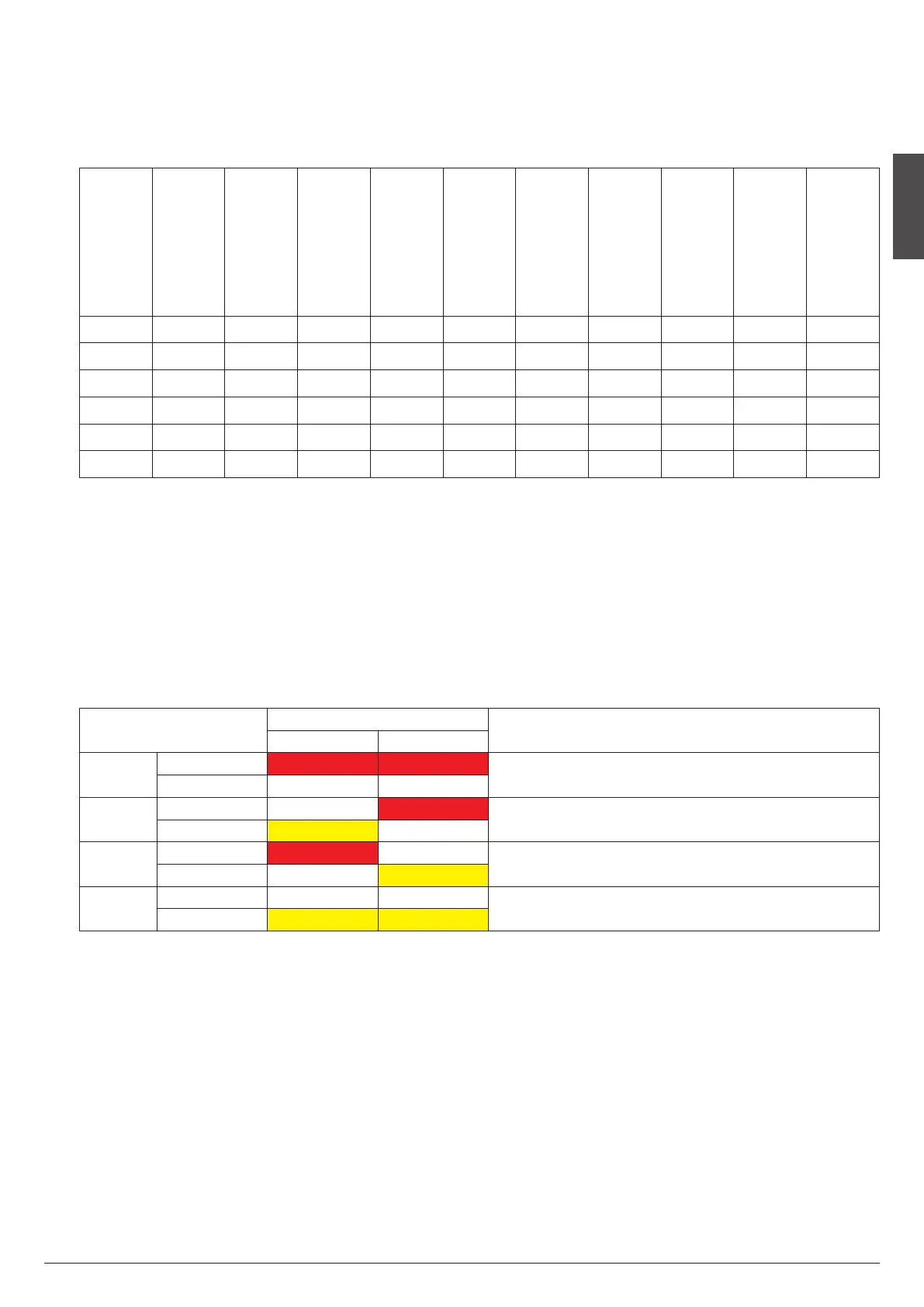

Low voltage

inputs

Condenser probe

Container Probe

Water level sensor

Defrosting start micro

Defrosting end micro

High voltage

inputs 230V/50HZ

Compressor

Tilting Motor

Hot gas electrovalve

Water electrovalve

Blades gear motor

Electric fan

Electronic board

English

17

71503816/0 - REV.0401/2013

8.5 FEATURES OF THE GAS REFRIGERATOR PLANT

FREON R134a

• Medium and maximum series “E” blade machines absorption

at room temperature of 32°C.

• Condensing pressure and evaporator temperature cycle start

and end at room temperature of 32°C.

* Expressed in water litres per hour at water temperature of

15°C and room temperature of 21°C

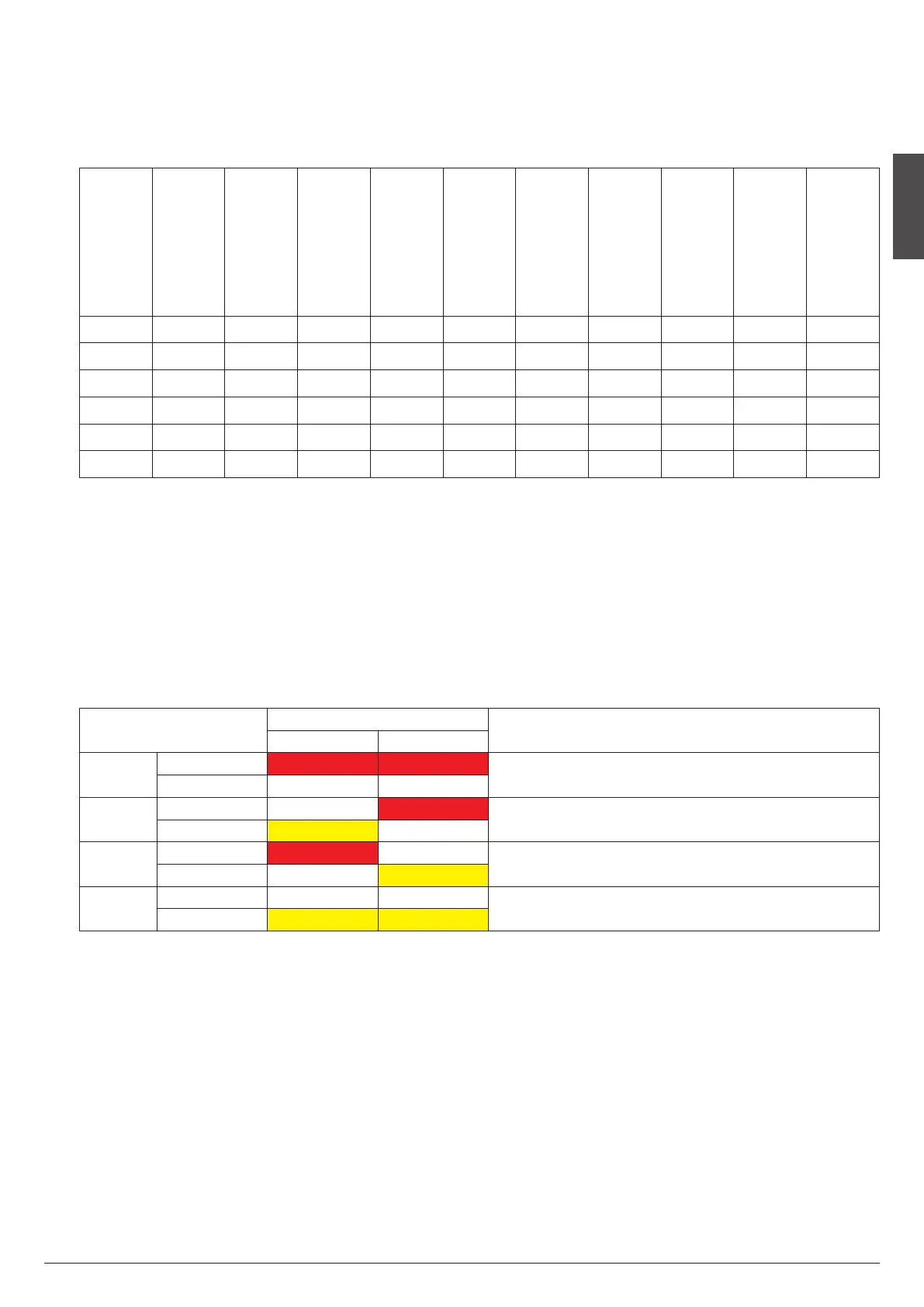

8.6 PROGRAMMED MAINTENANCE WARNING

• The programme

d maintenance time is set at 0 hour by the

manufacturer.

• In order to modify this time and/or reset the maintenance

recall function; proceed with dipswitch setup, as shown in

the attached table.

* In case of programmed maintenance, to reset and to restore

the programming to the initial value it's necessary to press

the RESET button for at least 5 seconds.

DIP

NOTE

1 2

1

OFF

Interval of maintenance to 0 hour

ON

2

OFF

Interval of maintenance to 2000 hours

ON

3

OFF

Interval of maintenance to 6000 hours

ON

4

OFF

Interval of maintenance to 3500 hours

ON

Machine

Gas

Max. ampere

Medium ampere

Condensing

pressure strarting

cycle (bar)

Evaporation

temperature

starting cycle (°c)

Condensing

pressure end cycle

(bar)

Evaporation

temperature end

cycle (bar)

Electrical

consumption

on 24 hrs/kw

Cubes for cycles and

weight singel cube

in gr

Water consumption

l/h*

E21 134 A 2 A 1,8 A 11,5 -3,3 9 -17 7,5 15/17 GR 6

E25 134 A 1,6 A 1,4 A 11 -2 9 -13 5,8 15/17 GR 2,8

E35 134 A 2,7 A 2,1 A 14 -2 10 -15 8,6 20/17 GR 4,7

E60 R134a 4,2 A 3,4 A 14,7 -2 11,3 -15 12,7 35/17 GR 7,5

E75 R134a 4,6 A 3,8 A 14,6 -2 11,4 -13 13,3 60/17 GR 9,4

E90 R134a 4,7 A 4,2 A 14,9 -2 10,8 -15 14,4 60/17 GR 12,5

Loading...

Loading...