English

14

SERVICE MODULARI06/2014

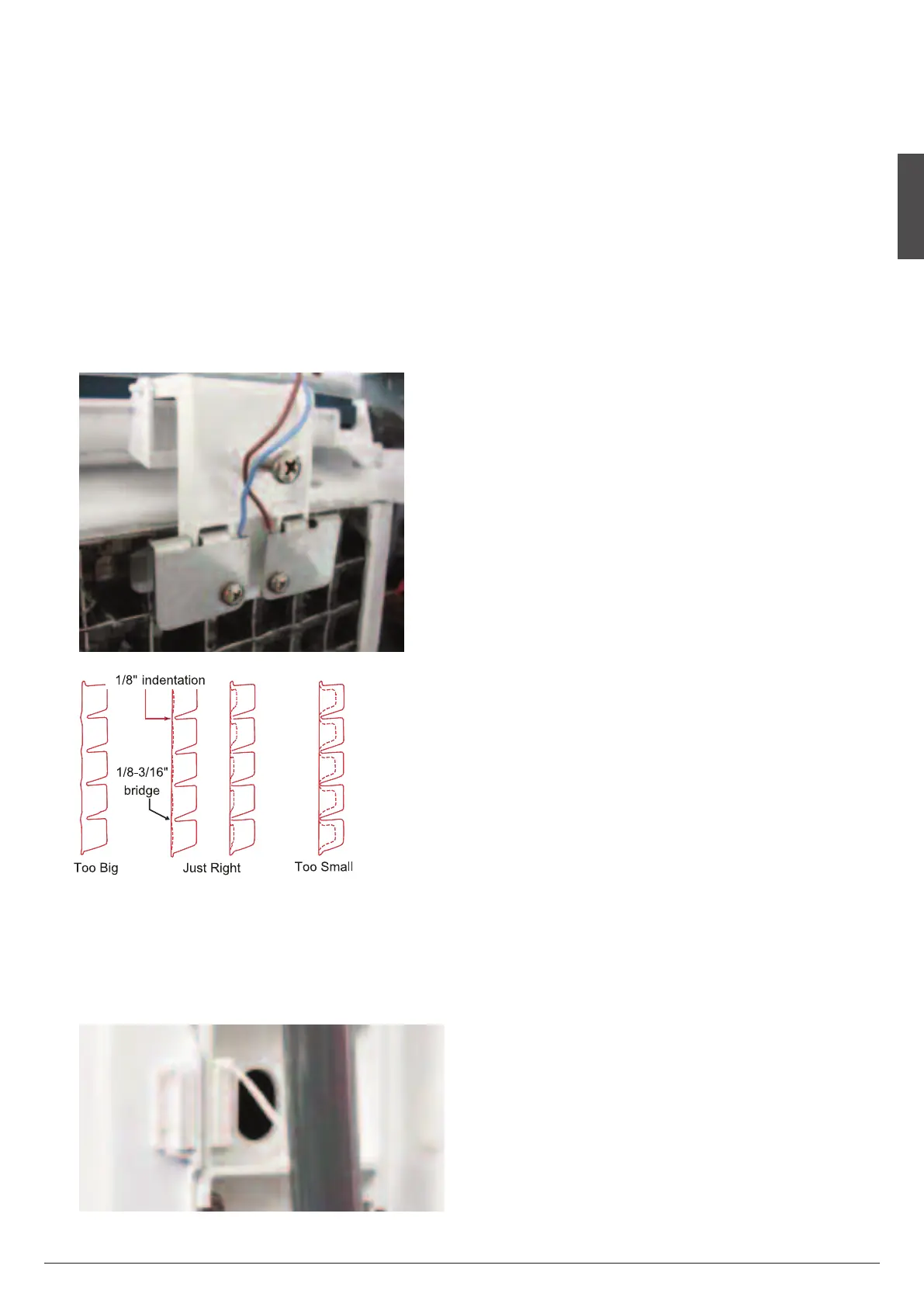

6.4 ICE THICKNESS SENSOR

• Located in the front upper right side off the evaporator, the

s

ensor is made with two metal reeds in which passes power

at low voltage. The two metal reeds, which are individually in

sulated, are set, through a setting screw, to maintain a mini

mum clearence from the evaporator 3÷5 mm.

• Once ice is formed into each mold and is thick enough to

fi

llup that minimum clearance existing between the two

sensor reeds and the evaporator, the water that cascades

over the ice has gradually approached to make contact be

tween the two sensor reeds.

• It is enough that this contact remains there for about 10 sec

onds that the P.C. Board receives the signals to put the ice

machine on defrost.

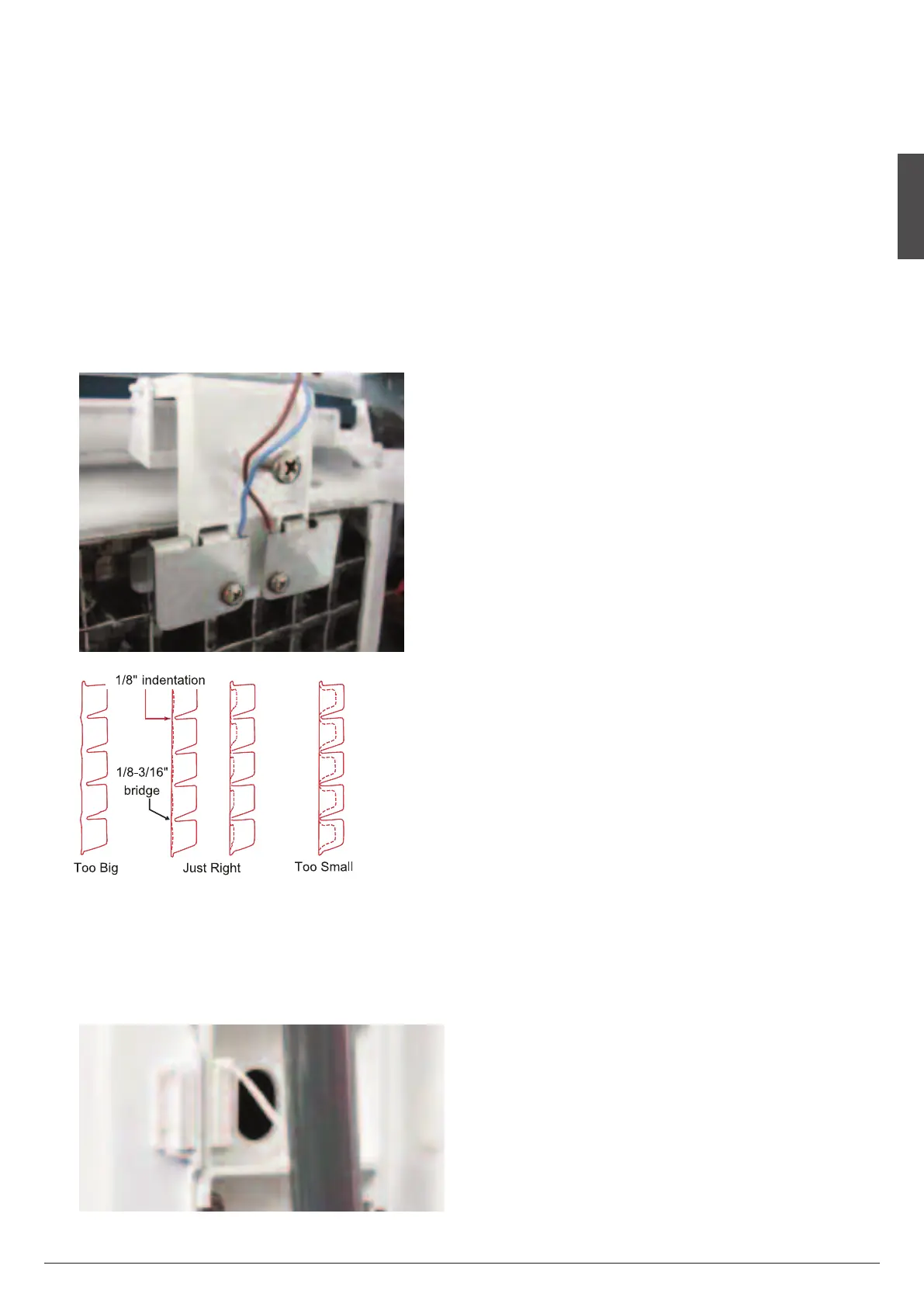

Ice Bridge Thickenss Measurement

6.5 MAGNETIC SWITCH

• Located in the front of the evaporator plastic curtain, this

switch sends a pulse to the P.C. Board which switches the

machine back in the freezing cycle.

6.6 HOT GAS SOLENOID VALVE

• The Hot Gas Solenoid Valve functions only during the Har

v

est Cycle, to divert the hot discharge gas from the Com

pressor, bypassing the Condendenser and thermostatic

expansion valve, for direct flow to the Evaporator Platen As

sembly to release ice cubes from the ice cube molds.

• The Hot Gas Solenoid Valve is comprised of two parts, the

B

ody & Plunger and the Coil assembles.

Installed in the discharge line of the Compressor, the ener

gized solenoid coil lifts the valve stem within the valve body

to cause the hot discarge gas to be diverted when the ice

Thickness sensor has signalled to the P.C. Board to start the

Harvest Cycle.

6.7 CONDENSER TEMPERATURE SENSOR

• The condenser temperature sensor probe located in con

tact with the condenser tube coil detects the condenser

temperature variations and signals them by supplying cur

rent, at low voltage, to the P.C. BOARD.

In the air cooled versions, in relation to the different current

received, the micro processor of the P.C. BOARD supplies,

through a TRIAC, the power at high voltage to the fan motor

so to cool the condenser and to reduce its temperature.

In case the condenser temperature rises and reaches 65°C

150°F the current arriving to the micro processor is such to

cause an immediate and total stop of the machine operation

with the blinking of the Red LED.

6.8 HIGH PRESSURE CONTROL

• The high Pressure Control, a safety control, is factory set to

cutout, at 30 bar and cutin at 22 bar.

• To shut OFF electrical power to Icemaker, should a loss of

water occur to the water cooled Condenser or a burnt out of

the fan motor on air cooled versions.

• The high Pressure Control is manual reset with reset button

B located on the Front Console Panel.

6.9 WATER REGULATING VALVE

Water Cooled Models

• The Water Regulating Valve functions maintain a constant

Compressor head pressure, by regulating the amount of in

coming water flow through the Condenser, on watercooled

models.

• The valve operate through the refrigerant system high side

pressure. Rotating the adjusting screw located on top of the

valve, can INCREASE or DECREASE the water flow through

the watercooled Condenser, which in turn, will DECREASE

or INREASE the Compressor operating head pressure.

Loading...

Loading...