English

7

SERVICE MODULARI 06/2014

3.3 HARVEST CYCLE

1. During the harvest cycle the components in operation are:

•

Hot Gas valve

• Harvest assist solenoid (pusher)

• Water Drain/Purge Valve

• Water Pump for the first 40"

• Compressor

a

nd both

• Machine Under Power

• Machine in Operation

2. 30 seconds after the beginning of the Harvest Cycle, the

Water Inlet Solenoid Valve is energized for 10 seconds only in

order to have a short flush of fresh water into the sump while

the Water Pump is still in operation.

3. The Fan Motor remains in OFF mode unless the Condenser

Sensor probe rise up to more then 38°C (same set up as per

end of freezing cycle).

4. When the ice plate is falling down from the evaporator, the

magnetic switch is activated for a while providing the signal

to the PC Board to restart a new freezing cycle.

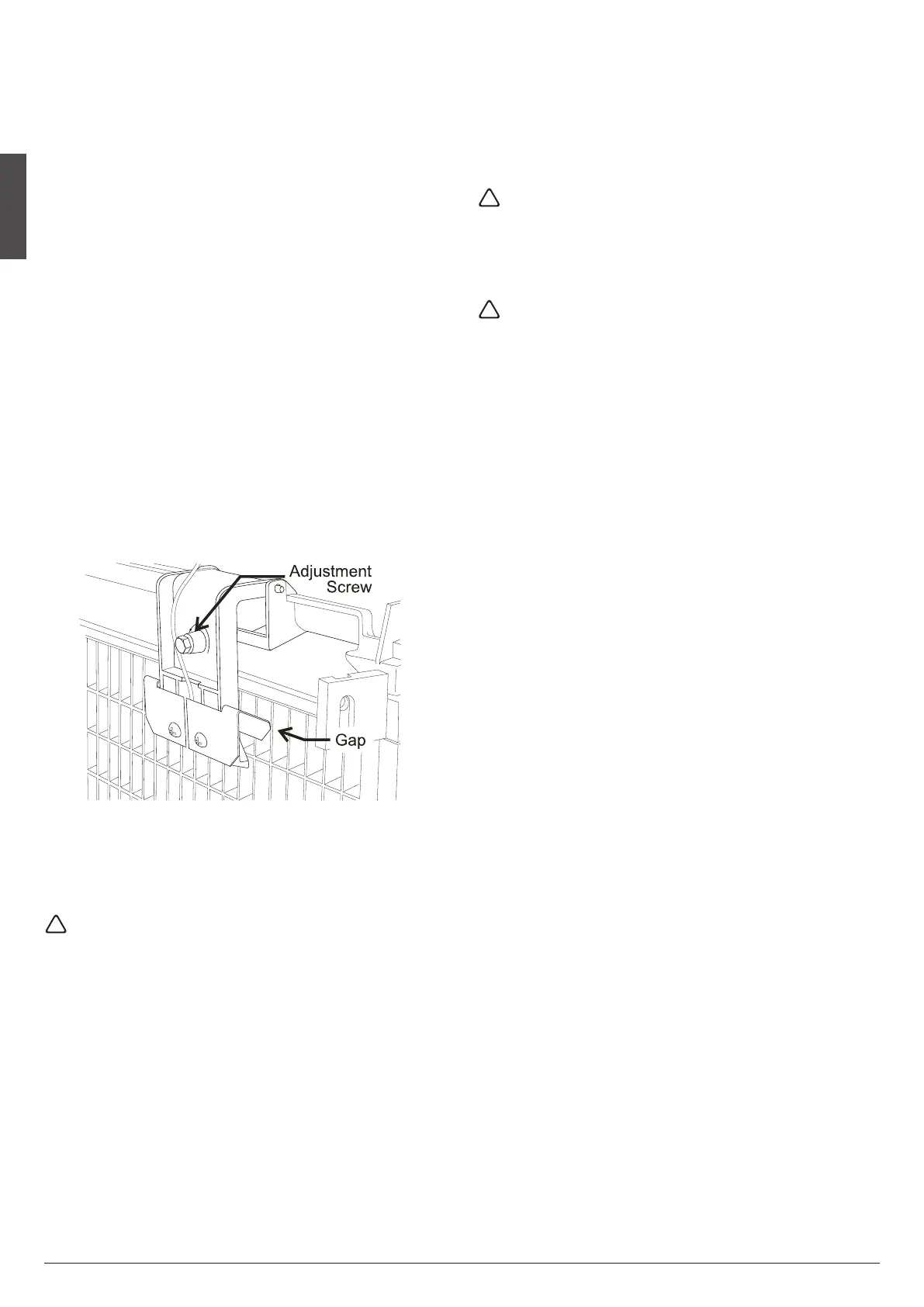

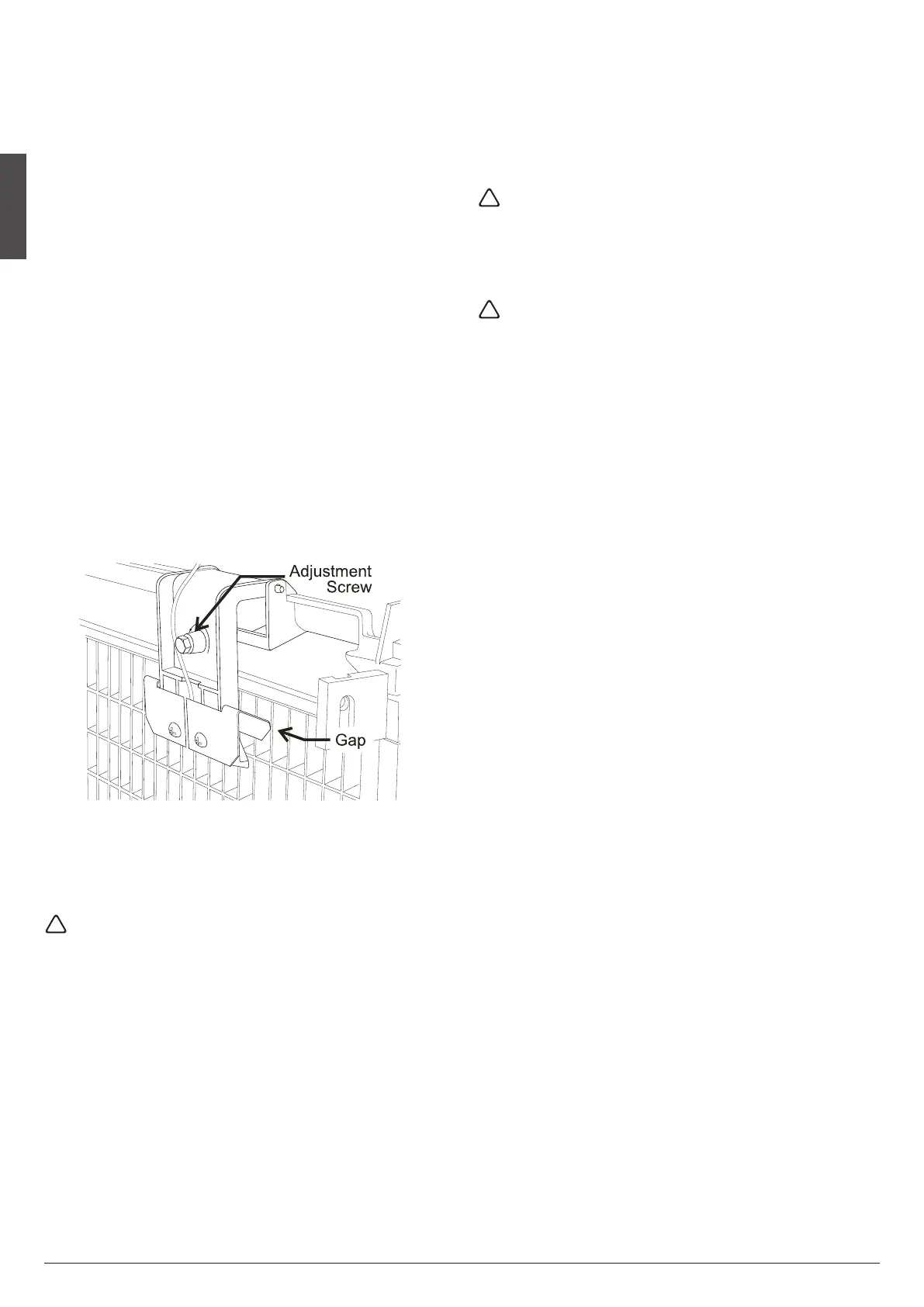

5. Observe first ice cube harvest and check size of ice cubes; if

an adjustment is required thread down or out screw N. 1 as

shown on below illustration.

Ice Thickness Sensor Adjustment

• This screw position determines the distance between the

sensor reeds and the eggcrate evaporator thus keeping the

ice cube at a proper thickness.

Note: This type of machine produce an "ICE PLATE" that breaks

when falls down into the storage bin. Setting the ice thickness

sensor in order to have single ice cubes may cause malfunction

of the machine.

6. Observe second and third cube harvest.

Check if size and shape combination is correct.

I

n areas where extreme problem water conditions exist, fil-

tering or purifyng equipment is recommended.

Note: If water used is too soft, "demineralized" the ice thickness

sensor might not be able to sense the water on its reeds, there by

i

t will not switch the unit on harvest cycle. A safety system built

in the P.C. Board switches the unit on harvest cycle whenever the

freezing period gets longer then 30 or 40 minutes.

Note: To assure a correct operation of the machine the water

must have a minimum electrical conductivity of 20 us.

7. Check operation of magnetic switch controlling it by keeping

open the bottom end of plastic deflector for more than 30

seconds. The machine must switch off at storage bin full.

Release the plastic deflector. The machine should restart in

the freezing cycle mode within few seconds going through

a 3 minutes delay time.

8. Place again all cabinet panels and screws previously re-

moved.

9. Thoroughly explain to owner/user the significant specifica-

tions of the ice maker start-up, reset and operation, going

through the procedures in the operating instructions.

Answer all questions about the ice maker by the owner and

inform the owner himseft of the name and telephone num-

ber of the authorized service agency serving him.

Loading...

Loading...