WARNING!

:

T

roubleshooting to be performed by qualied technicians

only. High voltage is dangerous – can cause injuries, death or property damage.

Troubleshooting

Symptom Remedy

Low speed

fan runs

continuously

• Verify you have 24 VAC between the R and C terminals

• Verify the high temperature limit switch is not open

• Check fuse to verify it is not blown

• Verify the fusible link is not damaged

• Temporarily bypass limits for troubleshooting only

No power to

the thermostat

(between R and

C terminals)

• Verify you have 24 volts between the SEC-1 and SEC-2 terminals

• Verify that the high temperature limit switch is not open

• Check fuse to verify it is not blown

• Verify the fusible link is not damaged

• Make sure the door interlock is bypassed while troubleshooting

No fan output in

cool mode

• Verify that you have 24 volts between GC and C

• Check fan connections at HI and COM

• Verify high speed fan operates correctly

No fan output in

heat mode

• Check for 24Vac voltage from R-C

• Check Thermostat call for 24VAC from terminals W to C

• Check Connections of Gas 1 and Gas 3

– Check for 24VAC from the Gas 1 terminal to C and from the Gas 3 terminal to

C on the ICM271. If there is no voltage at either of these points, the fan will not

work. Check for defective gas valve or loose /brokpen wires.

• VDP jumper plug broken off board.

• Check the Gas 1 – Gas 3 Jumper (on furnaces without ame proving circuit only)

– The GAS1-to-GAS3 connection is made by a three-wire ame-proof switch, but in

some standing-pilot applications this device is not present. In such applications, a

jumper must be installed between GAS1 and GAS3 terminals.

– A jumper should only be used on applications where a jumper exists on the

original equipment furnace fan control board when no ame proving switch

is installed. This jumper should also include a male 1/4” spade connector to

connect to your current gas valve’s wiring harness.

• Check fan connections at LO and COM

• Verify low speed fan operates correctly

Fan cycles on

and off

• Transformer may be damaged and creating an irregular sine wave

• Thermostat output signal may be outputting an irregular sine wave (especially solid state

thermostats)

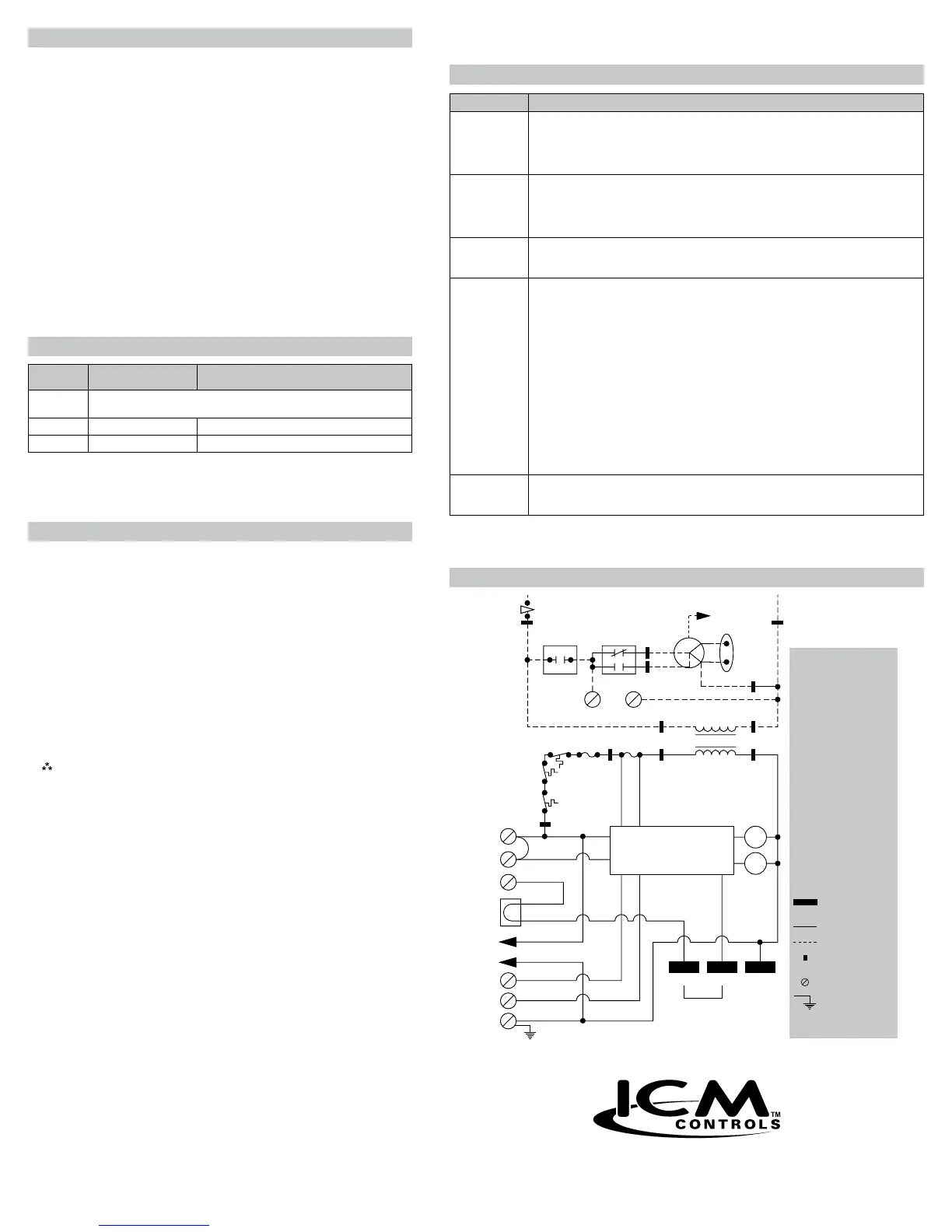

Legend:

AUXLS Auxiliary limit switch,

manual reset (SPST-

NC)

(Down ow furnace

models only)

BLWR Blower motor relay

(SPST-NO)

BVSS Blocked vent shut-off

switch, manual reset

(SPST-NC)

CAP Run capacitor

FL Fusible link

HI/LO Blower motor speed

change relay (DPST)

ITLK Blower door interlock

switch (SPST-NO)

LS Limit switch auto reset

(SPST-NC)

MTR Motor blower

TRANS Transformer

VDP Vent damper jumper

plug

Printed circuit

board terminal

24 VAC wiring

115 VAC wiring

Circuit on printed

circuit board

Screw terminal

Equipment ground

Not on all furnace

models

*

SEC-1

ITLK

HI/LOBLWR

LINE-1

EAC-2EAC-1

115 VAC

TRANS

24 VAC

SEC-2

PR-1 PR-2

COM

LINE-2

MTR

LO

HI

FUSEFLLS

*

BVSS

*

AUXLS

R

GH

W

VDP

GC

Y

C

GAS1 GAS3 GAS2

HI/LO

BLWR

LIM-1

LIM-2

JW-1

*

CAP

MICROPROCESSOR

Jumper

position

(if required)

Wiring Diagram

Installation Instructions

1. Be sure all electrical power is turned off.

2. Remove control box cover, exposing the old Carrier/BDP gas

furnace control center.

3. If furnace is equipped with a vent damper, disconnect the plug

connector from the old board.

4. Tag each wire as it is disconnected from the old furnace control

center. Disconnect all of the wiring hookups.

5. Remove the old Carrier/BDP furnace control center from the

control box.

6. Install the ICM271 fan control center into the control center box. Be

sure the top edge of the ICM271 is in the mounting slot, just like

the original board.

Note: If the ICM271 is not installed correctly (i.e. behind the

slot), an electrical short could occur.

7. Reconnect all of the wires (removed in Step 4, above) to the proper

terminals.

8. If the appliance had a vent damper, break the vent damper jumper

plug from the ICM271. Connect the original vent damper plug onto

the ICM271.

9. Restore electrical power to the furnace and put the furnace into

operation. Allow the furnace to run through one complete heating

or cooling cycle.

10. If the furnace is functioning properly, replace all panels and leave

this instruction sheet with the homeowner.

7313 William Barry Blvd., North Syracuse, NY 13212

(Toll Free) 800-365-5525 (Phone) 315-233-5266 (Fax) 315-233-5276

www.icmcontrols.com

ONE-YEAR LIMITED WARRANTY

The Seller warrants its products against defects in material or workmanship for a period of

one (1) year from the date of manufacture. The liability of the Seller is limited, at its option,

to repair, replace or issue a non-case credit for the purchase prices of the goods which are

provided to be defective. The warranty and remedies set forth herein do not apply to any

goods or parts thereof which have been subjected to misuse including any use or application

in violation of the Seller’s instructions, neglect, tampering, improper storage, incorrect

installation or servicing not performed by the Seller. In order to permit the Seller to properly

administer the warranty, the Buyer shall: 1) Notify the Seller promptly of any claim, submitting

date code information or any other pertinent data as requested by the Seller. 2) Permit the

Seller to inspect and test the product claimed to be defective. Items claimed to be defective

and are determined by Seller to be non-defective are subject to a $30.00 per hour inspection

fee. This warranty constitutes the Seller’s sole liability hereunder and is in lieu of any other

warranty expressed, implied or statutory. Unless otherwise stated in writing, Seller makes no

warranty that the goods depicted or described herein are t for any particular purpose.

LIAF044-2

• Turn off gas supply and electrical power to equipment before

servicing

CAUTION!

:

Do not use this option on paired furnace

applications.

The ICM271 has different blower speed options to match a specic

application (see chart). The blower speed option used on the original

furnace control may be very difcult to determine.

1. If the old Carrier/BDP unit has (2) black relays just like the ICM271,

then look for the JW1 jumper and R17 resistor on the Carrier/BDP

board. They will be in the same location as the JW1 and R17 on

the ICM271. If either one (JW1 or R17) has been cut, then cut the

ICM271 equivalent. This will match the original Carrier/BDP blower

speed option.

Blower Speed Output

Input From

Thermostat

ICM271

As Shipped

G Blower Operation

(Cut R17 Resistor)

W

Lo-Speed Heating Blower with

75 seconds ON Delay and 105 seconds OFF Delay

G Hi-speed cooling blower Lo-speed heating blower

Y No blower Hi-speed cooling blower with 90 second OFF delay

Blower Operating Modes

Loading...

Loading...