3

MAINTENANCE

AND

ADJUSTMENT

8-7

ADJUSTMENTS

Your

IC-725

has been thoroughly adjusted and

checked

at

the

factory before

being shipped.

All

adjustable

trimmers

and

coils

should

be

adjusted

by

an

authorized

Icom

Dealer

or

Service

Center.

Your

transceiver

warranty

does

not

cover

problems

caused

by

unauthorized

internal

adjustments.

(1)

MAIN

DIAL BRAKE

ADJUSTMENT

The

tension of the

MAIN

DIAL

may

be

adjusted

to

suit

your

operating

requirements.

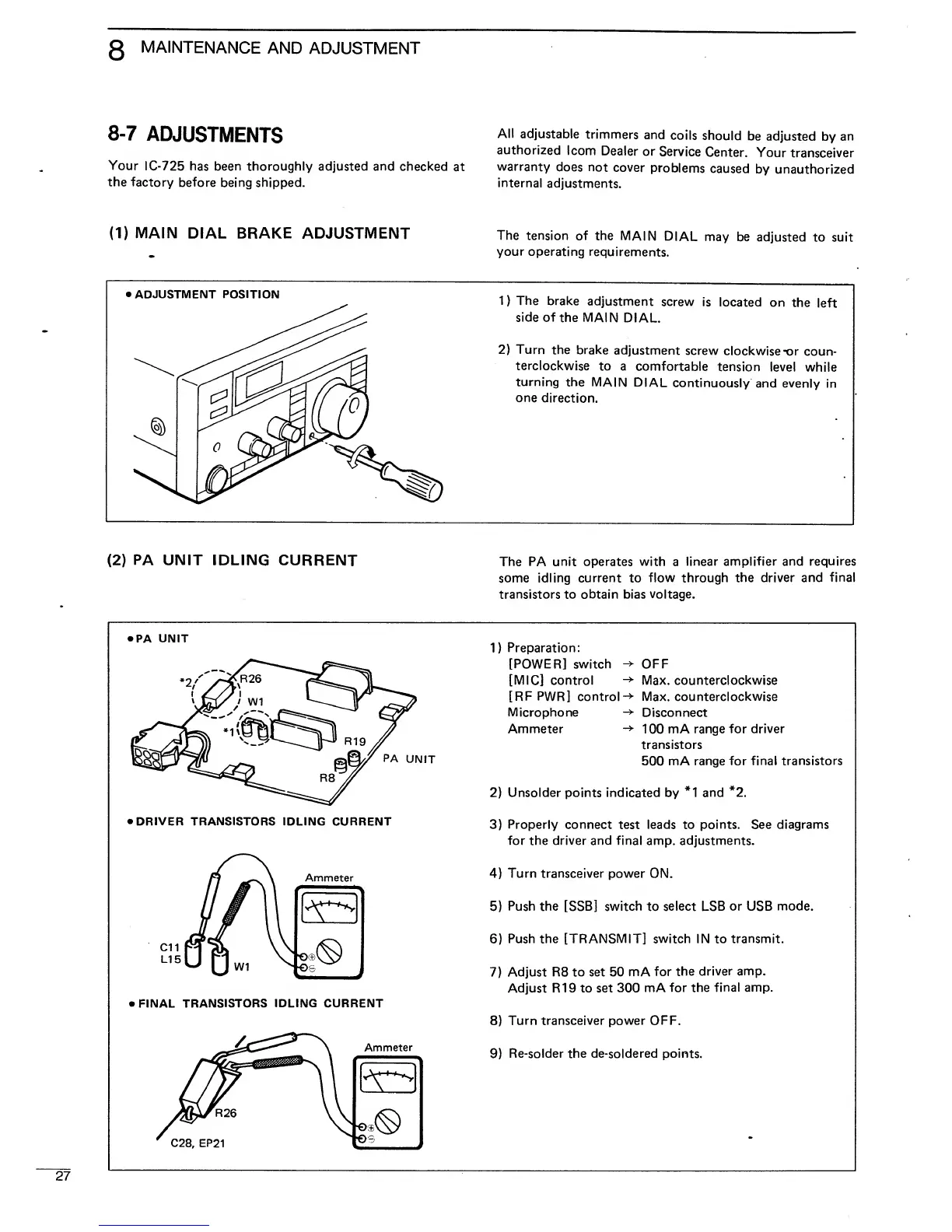

•

ADJUSTMENT POSITION

1

)

The

brake

adjustment

screw

is

located

on

the

left

side of

the MAIN

DIAL.

2)

Turn

the

brake

adjustment

screw

clockwise

-or

coun-

terclockwise

to a

comfortable

tension

level

while

turning

the

MAIN

DIAL

continuously

and evenly

in

one

direction.

(2)

PA

UNIT IDLING

CURRENT

The PA unit operates with

a

linear amplifier and

requires

some

idling current

to

flow through

the driver and

final

transistors to obtain bias

voltage.

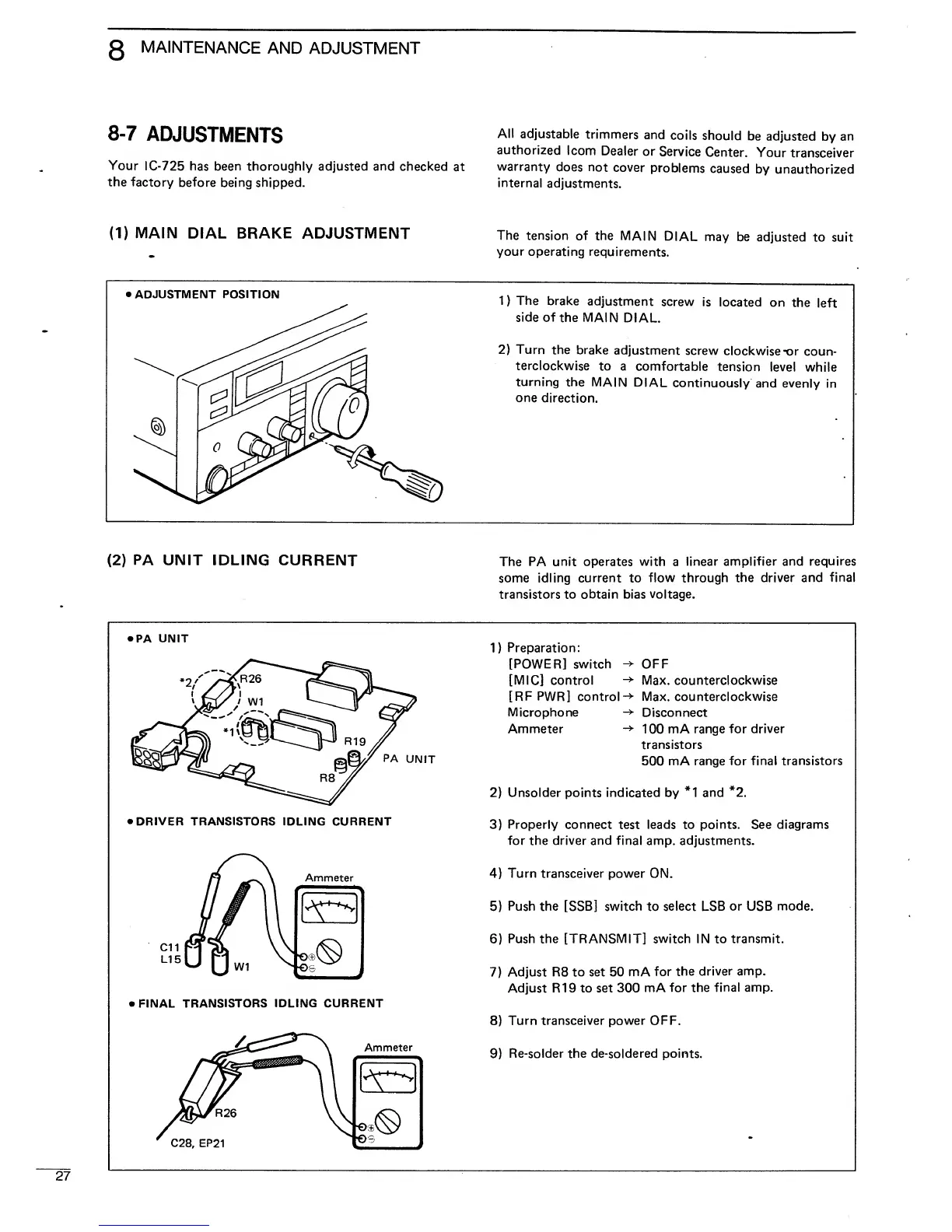

»PA UNIT

PA

UNIT

•

DRIVER TRANSISTORS

IDLING CURRENT

Ammeter

>

FINAL

TRANSISTORS

IDLING CURRENT

Ammeter

1)

Preparation:

[POWER] switch

->

OFF

[MIC] control

-+

Max. counterclockwise

[RF PWR] control-*

Max.

counterclockwise

Microphone

-»

Disconnect

Ammeter

100 mA range

for driver

transistors

500 mA

range for final transistors

2)

Unsolder points indicated by

*1

and

*2.

3)

Properly

connect test leads to points. See diagrams

for the

driver

and final amp. adjustments.

4)

Turn transceiver power

ON.

5)

Push the [SSB] switch

to

select LSB or USB

mode.

6)

Push the [TRANSMIT] switch IN to transmit.

7)

Adjust R8 to set 50 mA

for

the

driver amp.

Adjust R19 to set

300 mA

for the

final amp.

8)

Turn transceiver power OFF.

9)

Re-solder the de-soldered points.

C28, EP21

Loading...

Loading...