54

SERVICING

isar - Installation and Servicing

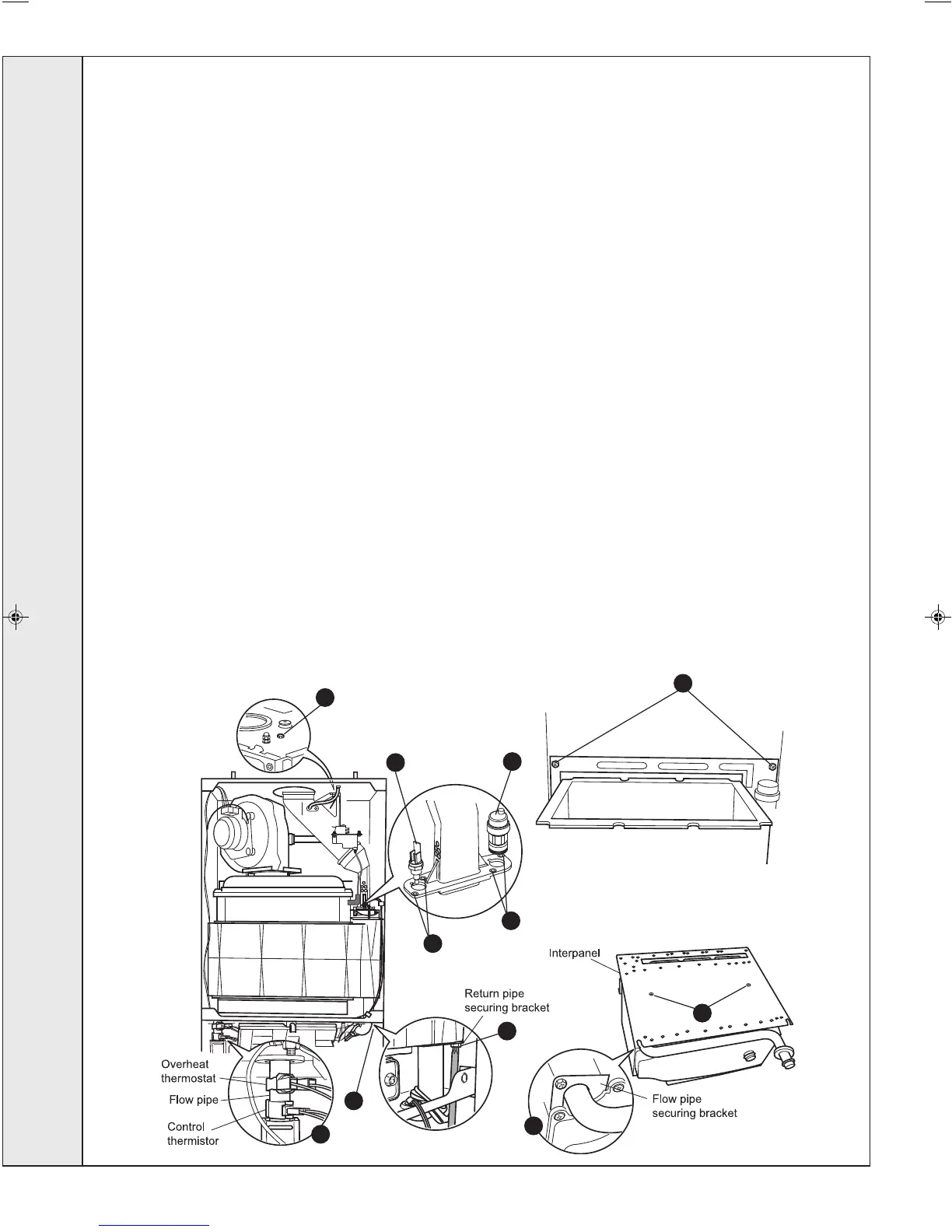

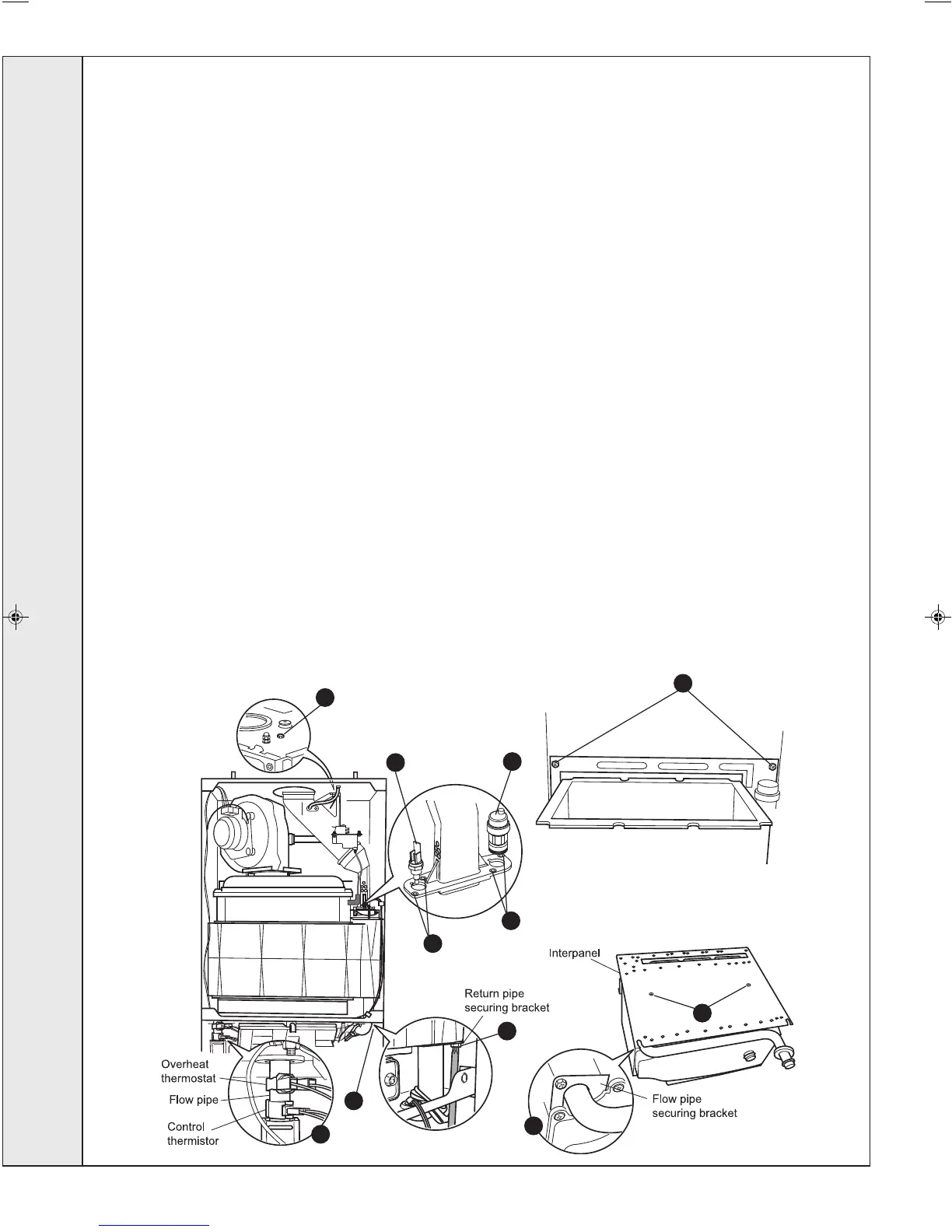

Refer also to Frame 8 - 'Boiler Exploded View'.

IMPORTANT

Before starting the removal procedure, protect the gas and

electrical controls with a waterproof sheet or plastic bag.

1. Refer to Frame 57.

2. Remove the boiler front, bottom and sealing panels.

Refer to Frames 49 & 50.

3. Drain the boiler. Refer to Frame 77.

4. Remove the control box and place on one side. Refer to

Frame 71.

5. Remove the fan / venturi assembly and place on one

side. Refer to Frame 52.

6. Remove the burner and place on one side. Refer to

Frame 53.

7. Remove the ignition and detection electrodes. Refer to

Frames 63 & 64.

8. Remove the spark generator. Refer to Frame 65.

9. Release the flue from the turret. Refer to Frame 26.

10. Remove the turret from the boiler. Refer to Frame 26.

11. Release the silicone tubing from the sampling point.

12. Release the electrical connection to the dry fire

thermistor.

13. Remove the M5 x 10 screw retaining the top flue manifold

casting.

14. Remove the top casting of the flue manifold from the

appliance.

15. Remove the automatic air vent. Refer to Frame 76.

16. Undo the 4 M x 10 screws securing the bottom flue

manifold casting and remove.

81

HEAT ENGINE REPLACEMENT

17. Remove the edge clip securing the dry fire thermistor

wiring.

18. Remove the blind grommet to gain access to the return

pipe securing bracket.

19. Remove the M5 screw and remove the return pipe

securing bracket by sliding forwards.

20. Remove the overheat thermostat and the control

thermistor. Refer to Frame 62.

21. Remove the securing pin to release the flow pipe.

22. Remove the condensate ‘S’ trap. Refer to Frame 69.

23. Remove the 2 M5 screws securing the interpanel to the

back panel.

24. Slide the heat exchanger and interpanel assembly upward

to disengage and remove from the casing, complete with

the flow pipe.

25. Remove the 2 M6 countersunk screws, remove the

interpanel and transfer to the new heat exchanger.

26. Remove the M5 screw and remove the flow pipe securing

bracket.

27. Remove the flow pipe and transfer to the new heat

exchanger.

28. Reassemble in reverse order, replacing gaskets or seals

if any sign of damage or deterioration is evident.

Note. The heat exchanger is supplied with new combustion

chamber insulation boards. These should be fitted (refer

to Frame 68 before the burner and fan / venturi

assembly and before the ignition and detection

electrodes are replaced).

29. Refill the boiler. Refer to Frame 36.

30. Check operation of the boiler. Refer to Frame 57.

nm8768

23

13

12

15

16

16

18

20

19

26

25

SERVICING

203319-3.pmd 27/03/2008, 08:1554

Loading...

Loading...