19

HS5L Interlock Switches with Solenoid

Safety Precautions

• In order to avoid electric shock or re, turn power off before

installation, removal, wiring, maintenance, or inspection of the

interlock switch.

• If relays are used in the circuit between the interlock switch

and the load, use only safety relays, since welded or sticking

contacts of standard relays may invalidate the functions of the

interlock switch. Perform a risk assessment and make a safety

circuit which satises the requirements of the safety category.

• Do not place a PLC in the circuit between the interlock switch

and the load. Safety security can be endangered in the event of

a malfunction of the PLC.

• Do not disassemble or modify the interlock switch, otherwise a

malfunction or an accident may occur.

• Do not install the actuator in a location where a human body may

come into contact. Otherwise injury may occur.

• Solenoid lock is locked when energized, and unlocked when

de-energized. When energization is interrupted due to wire

disconnection or other failures, the interlock switch may be

unlocked causing possible danger to the operators. Solenoid

lock must not be used in applications where locking is strictly

required for safety. Perform a risk assessment and determine

whether solenoid lock is appropriate.

• When changing the head orientation, disconnect the cable and

turn the manual unlock to the UNLOCK position in advance. If

the head orientation is changed when the cable is connected

and the manual unlock is in the LOCK position, machines may

start to operate, causing danger to the operators.

• HS5L interlock switches are Type 2 low level coded

interlocking devices (ISO14119). According to ISO14119, the

following is required to minimize defeat when installing and

constructing systems:

1. Prevent dismantling or de-positioning of the elements of

the interlocking device by use of non-detachable xing (e.g.

welding, gluing, one-way screws, riveting). However, use of

non-detachable xing can be an inappropriate solution in

cases where a failure of the interlocking device during lifetime

of the machinery can be expected and a fast change is

necessary. In this case measures mentioned below, should be

used to provide the required level of risk reduction.

2. Apply at least one out of the four measures below.

➀ Mounting out of reach.

➁ Physical obstruction or shielding.

➂ Mounting in hidden position.

➃ Integration of defeat monitoring by means of status

monitoring/cyclic testing.

• Do not use the interlock switch as a door stop. Install a

mechanical door stop at the end of the door to protect the

interlock switch against excessive force.

• Do not apply excessive shock to the interlock switch when

opening or closing the door. A shock to the interlock switch

exceeding 1,000m/s

2

may cause damage to the interlock

switch.

• Prevent foreign objects such as dust and liquids from

entering the interlock switch while connecting a conduit or

wiring.

• Plug the unused actuator entry slot using the slot plug

supplied with the interlock switch.

• Do not store the interlock switches in a dusty, humid, or

organic-gas atmosphere, or in an area subjected to direct

sunlight.

• Use proprietary actuators only. When other actuators are

used, the interlock switch may be damaged.

• The locking strength is rated at 1400N. Do not apply a load

higher than the rated value. When a higher load is expected,

provide an additional system consisting of another interlock

switch without lock (such as the HS5D interlock switch) or a

sensor to detect door opening and stop the machine.

• Regardless of door types, do not use the interlock switch

as a door lock. Install a separate lock using a latch or other

measures.

• While the solenoid is energized, the switch temperature

rises approximately 40°C above the ambient temperature (to

approximately 95°C while the ambient temperature is 55°C).

Do not touch to prevent burns. If cables come into contact

with the switch, use heat-resistant cables.

• Although the HS9Z-A51A/A52A actuators alleviate shock

when the actuator enters a slot in the interlock switch, make

sure that excessive shock is not applied. If the Rubber

Bushings become deformed or cracked, replace with new

ones.

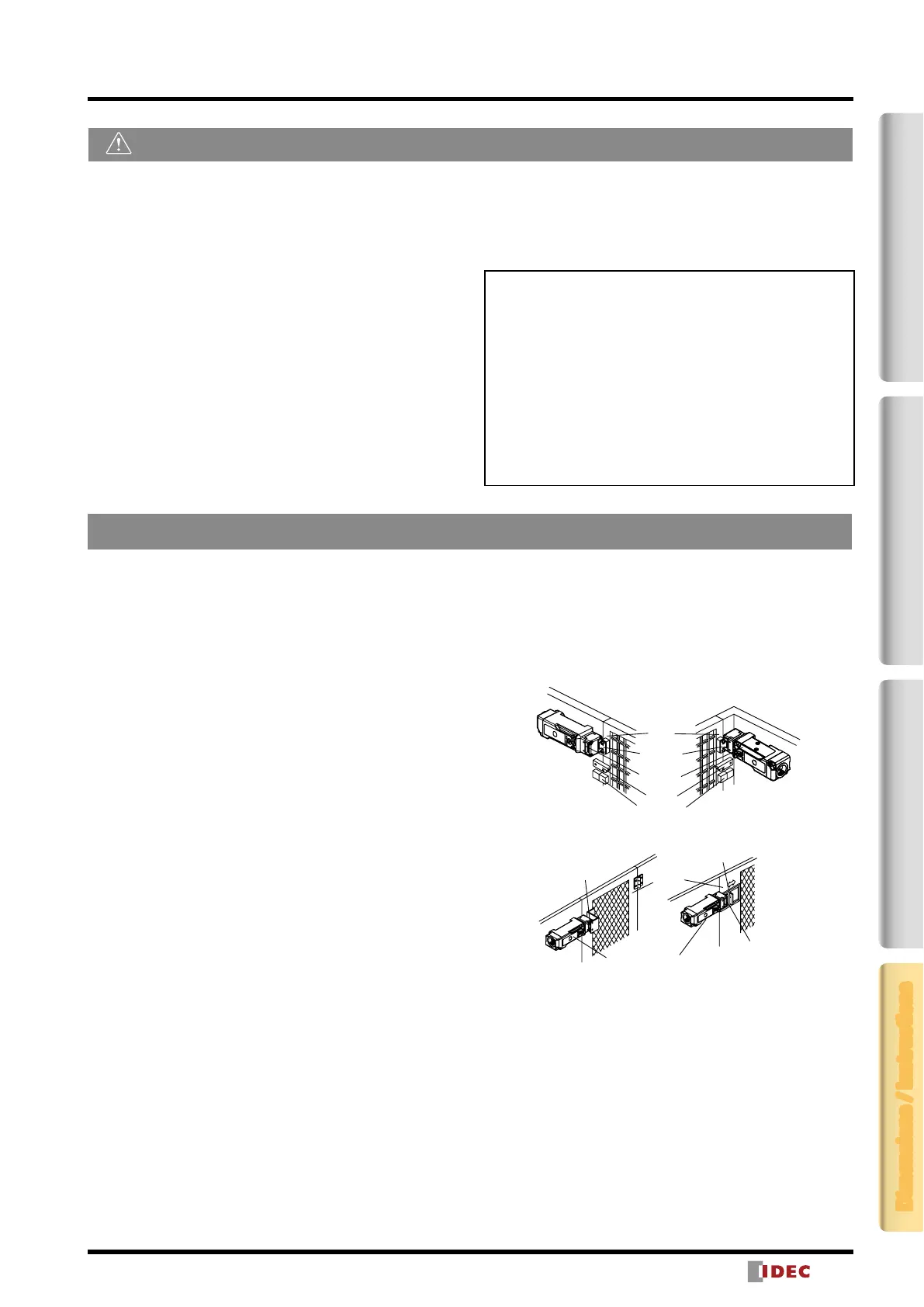

Mounting Examples

Refer to the following drawing for the installation. Mount the

interlock switch to a xed machine or guard, and actuator

on the hinged door. Do not mount both interlock switch and

actuator on the hinged doors. This may result in the actuator

being inserted at a wrong angle to the interlock switch,

resulting in malfunction.

Application of Sliding Doors

Door

HS9Z-A51

Actuator

HS5L

Interlock

Switch

Latch

Door Stop

Door

HS9Z-A51

HS9Z-A52

Actuator

Actuator

HS5L

Interlock Switch

Latch

Application of Hinged Doors

Instructions

2-Contact4-ContactActuatorDimensions / Instructions

Loading...

Loading...