4| Heating starts by pressing .

5| LED turns off when heating is completed.

6| Open the heater cover and take out the fiber. Do not touch the protecting sleeve or heater at any point

during or right after heating.

7| Conduct a final inspection to check for bubbles, fragments or dust on the sleeve.

4.7

| USE OF WORK BELT

The work belt of Swift KF4 is a type of auxiliary equipment that combines with its main body to facilitate

working at a manhole, utility pole, etc.

|

WORK BELT COMPONENTS

MAINTENANCE OF SPLICE QUALITY

5.1

| CLEANING AND INSPECTION BEFORE SPLICE

5.1.1

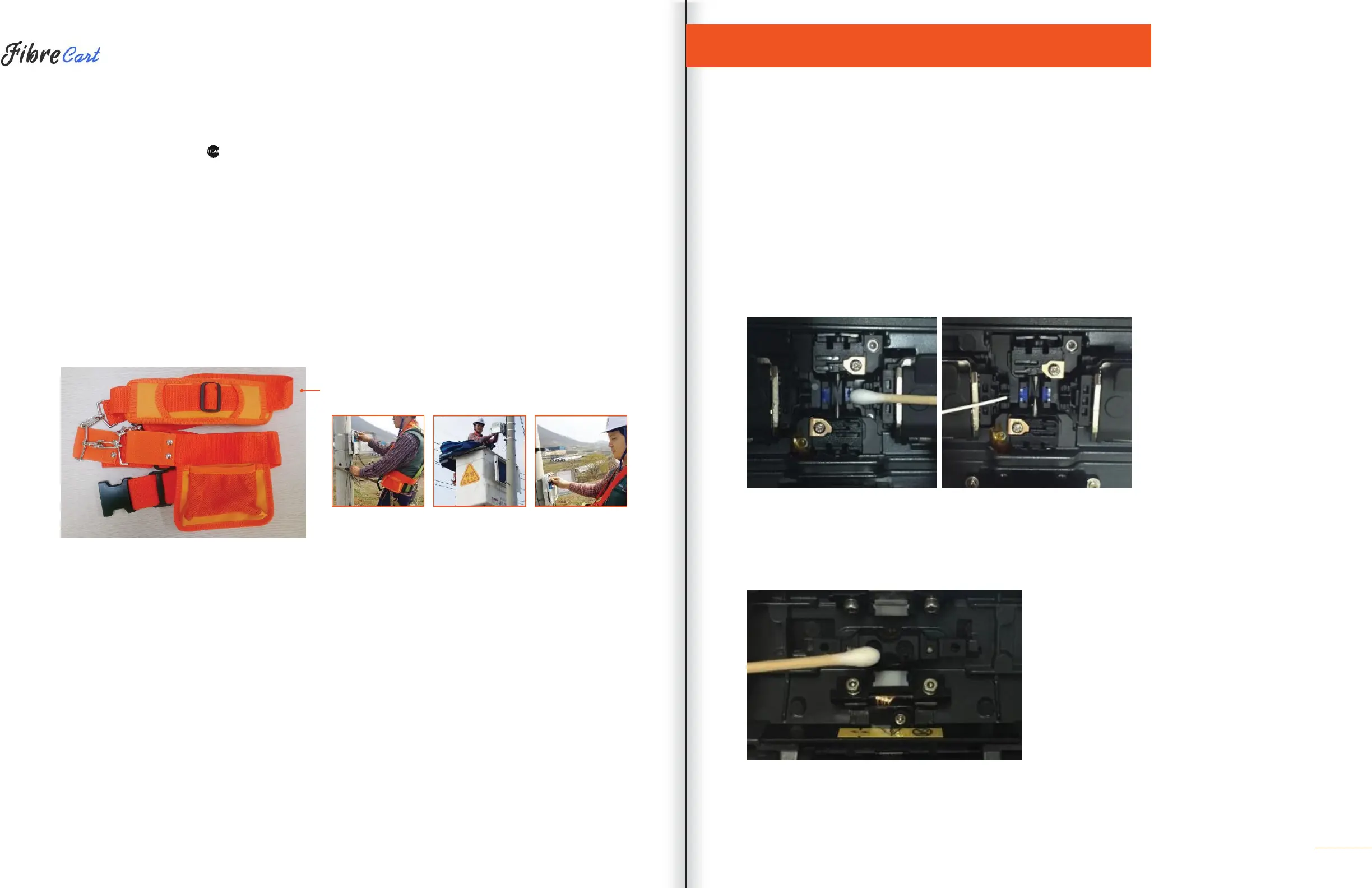

V-GROOVE CLEANING

When the inside of the V-groove is contaminated, splice quality may deteriorate. It is important to regularly

inspect and frequently clean the V-groove as follows.

1| Open the wind cover.

2| Clean the V-groove using a cotton swab moistened with alcohol and any proper cleaning agents. Remove

the remaining alcohol from the V-groove using a clean, dry, lint-free cotton swab.

3| When a foreign substance cannot removed with a cotton swab, clean it with the tip of a cleaved fiber and

repeat the steps above.

5.1.2

PUSHER BLOCK CLEANING

Pusher block contamination causes poor splice quality due to irregular pressure applied to the fibers. It is

important to frequently inspect and regularly clean it.

Loading...

Loading...