7.3

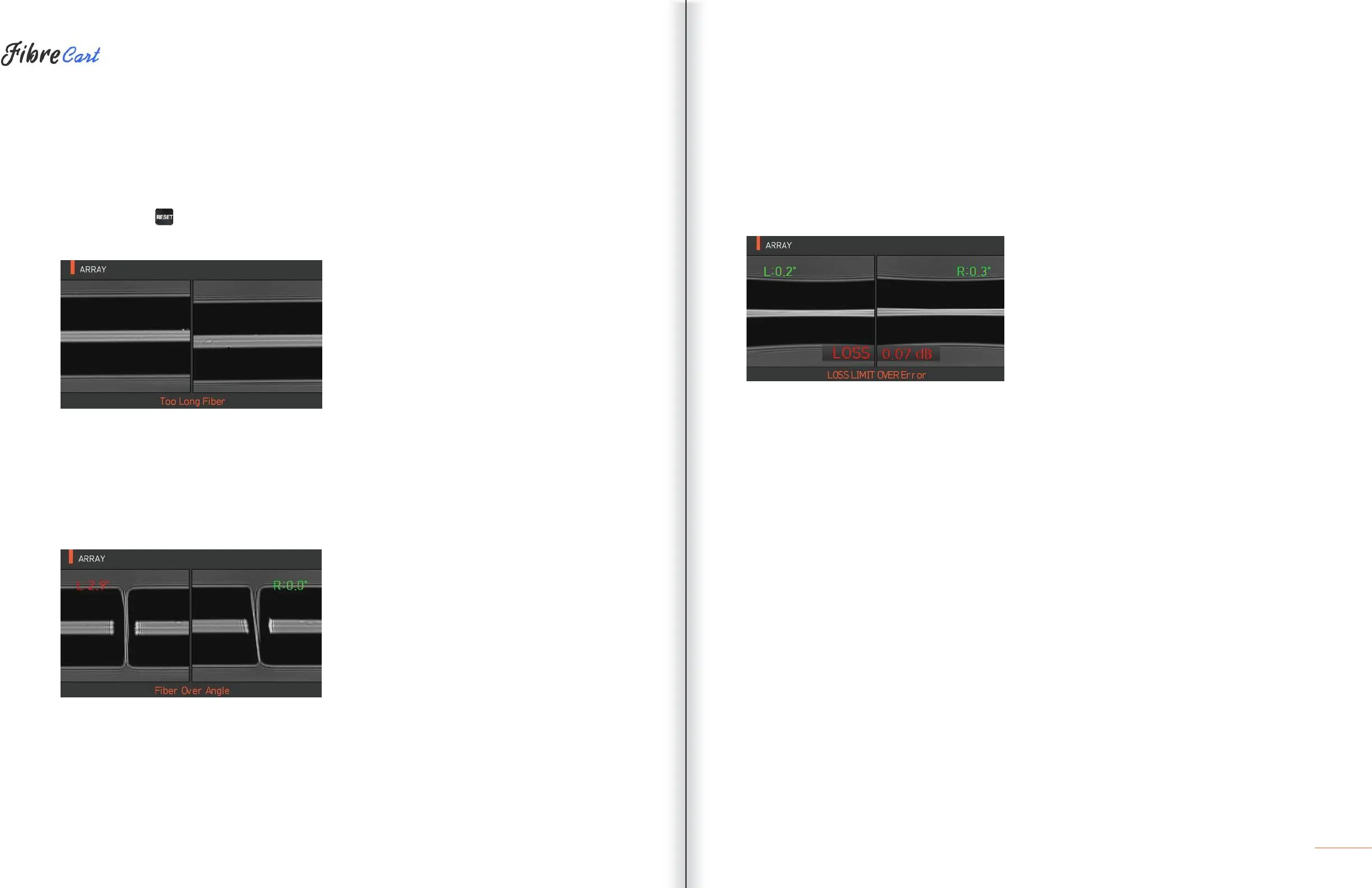

| TOO LONG FIBER

Error message generated when the fiber is located too close to the electrodes, object lens or reflector is dirty,

or the LED is not bright enough.

SOLUTION: Press and reposition fiber. Clean the object lens and reflector. Conduct an LED test. If an error

occurs upon performing the LED test, contact UCLSWIFT.

7.4

| FIBER OVER ANGLE

Error message generated when the cleaved angle of the fiber is higher than specified.

SOLUTION: Check the state of the fiber cleaver. Check the cleaved angle limit.

7.5

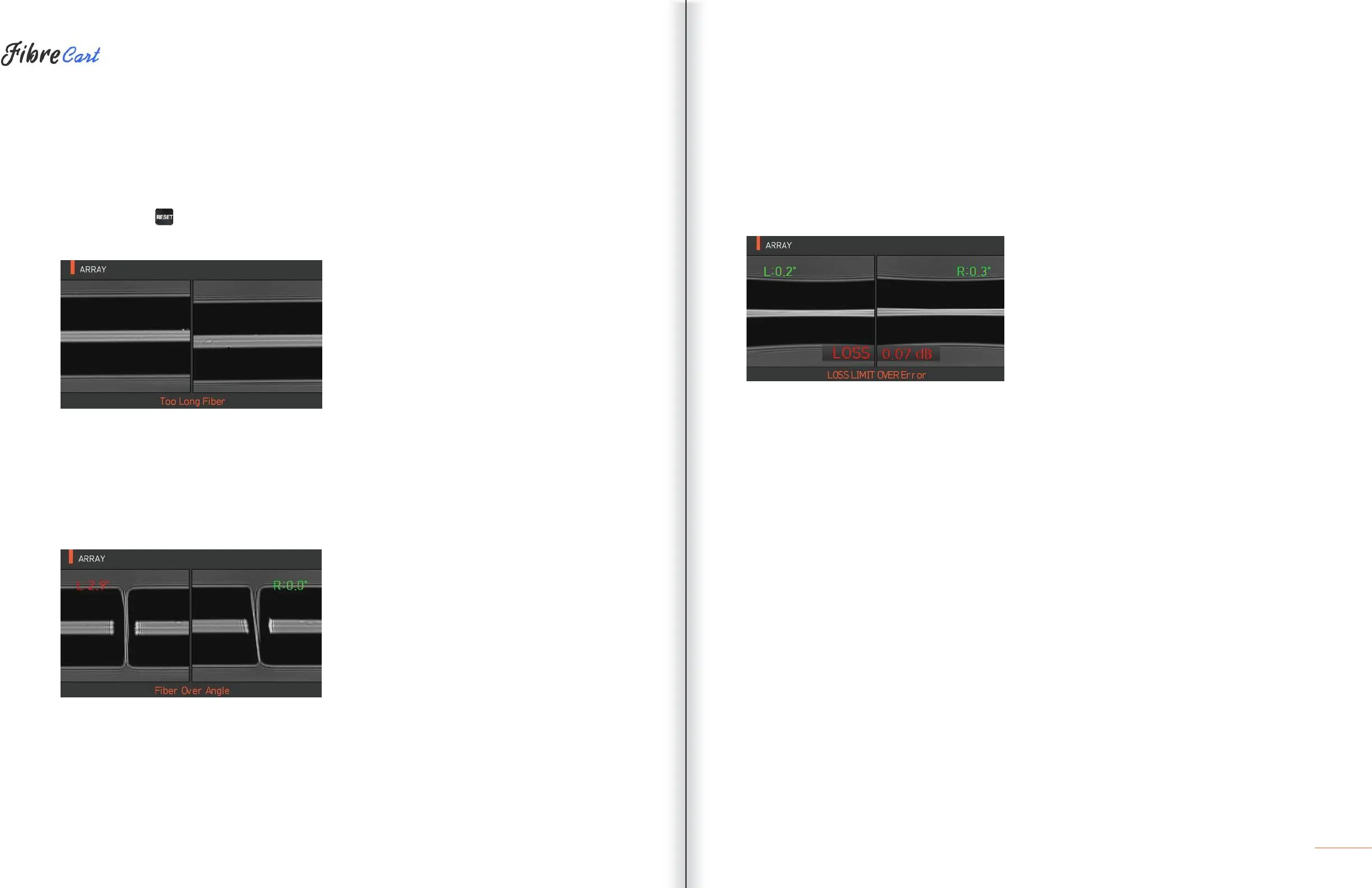

| LOSS LIMIT OVER

Error message generated when the estimated loss value is higher than the preset loss factor limit.

SOLUTION: Check the loss factor limit.

7.6

| FIBER THIN ERROR

Error message generated when the spliced point becomes thinner than the standard after splicing.

SOLUTION: Make an adjustment to shorten the pulling length of the pulling splice. Check whether the arc

amount or arc time is set as too large or too long.

7.7

| FIBER THICK ERROR

Error message generated when the spliced point becomes thicker than the standard after splicing.

SOLUTION: Reduce the overlap set value. Check whether the arc amount or arc time is set as too small or

too short.

7.8

| BUBBLE ERROR

Error message generated when there are bubbles or spots being generated on spliced point after splicing.

SOLUTION: Examine the fiber cleaver. Clean the V-groove. Examine the electrodes.

7.9

|

CLEAVED SURFACE ERROR

Error message generated when the cut surface of the fiber is of poor quality.

SOLUTION: Check the condition of the fiber cleaver. Re-cleave the fiber.

Loading...

Loading...