Technical documentation Technical documentation

STES ed 07/01

EOLO STAR

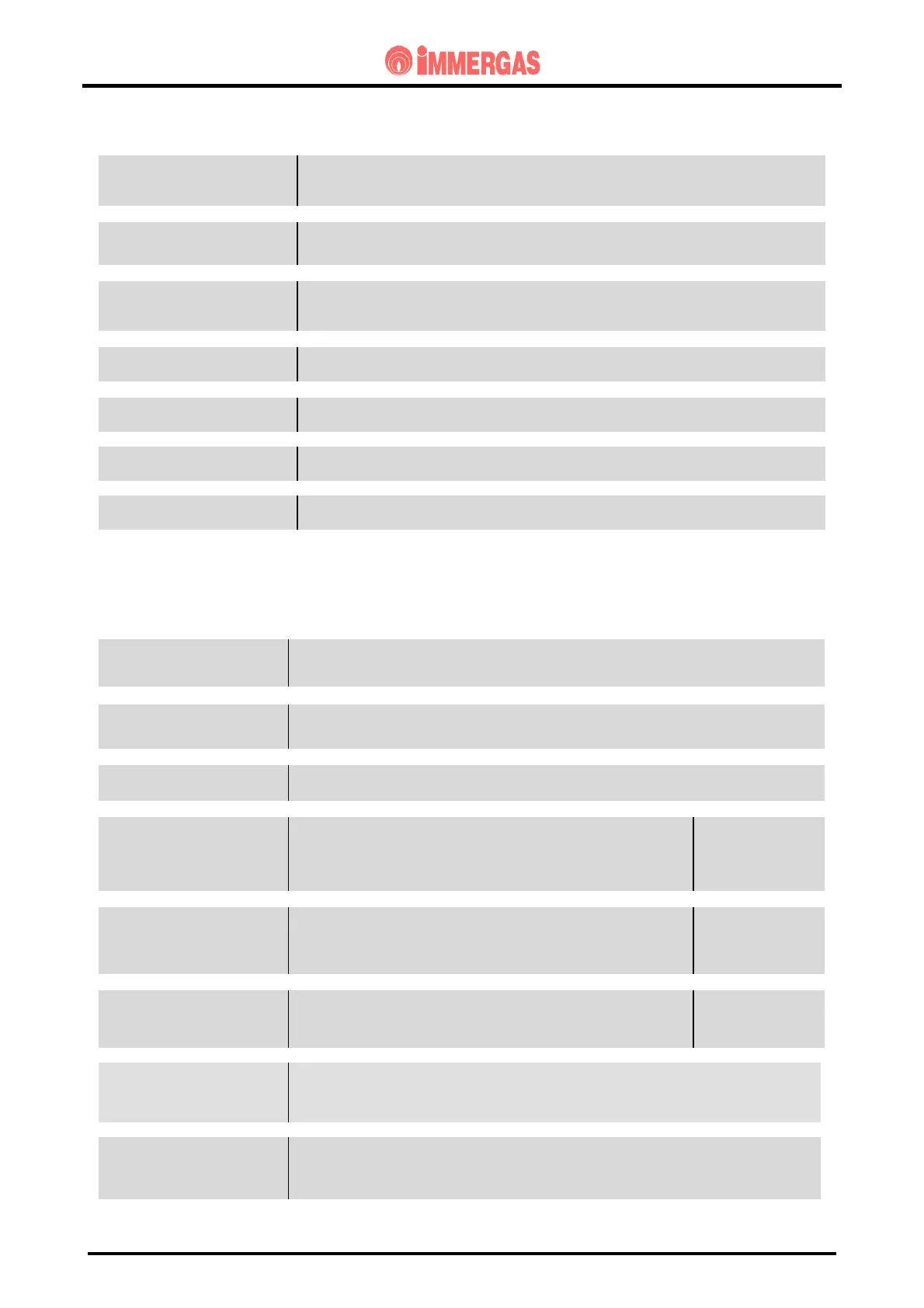

OUTPUTS

Modulation coil

(MOD)

This is a positive square-wave signal with variable ON-OFF ratio (duty-cycle) that controls

the modulation coil of the gas valve and makes it possible to alter gas pressure to the

burner.

Ignition electrode

(E1)

This is a high voltage signal (about 16 kV) for energising the ignition electrode on the

boiler.

Programmer clock

(OP)

Permits energising the programmer clock at 230 V AC (optional). This can be fitted on the

boiler dashboard after removing the closing plate.

The signal is operative with master switch in 0 position. SUMMER and WINTER.

PUMP RELAY

This is a single-pole relay for controlling the pump (MP). It is excited when operation is

required.

REQUEST RELAY

This is a single-pole relay which is excited when the burner has to be ignited.

By means of its contact, the adjustment board ignition circuit is controlled.

V/G RELAY

This is a single-pole relay that is excited by the ignition circuit to energise the main gas

valve coils (VG).

FAN RELAY

This is a single-pole relay for controlling the fan (MV) which is excited when operation is

required.

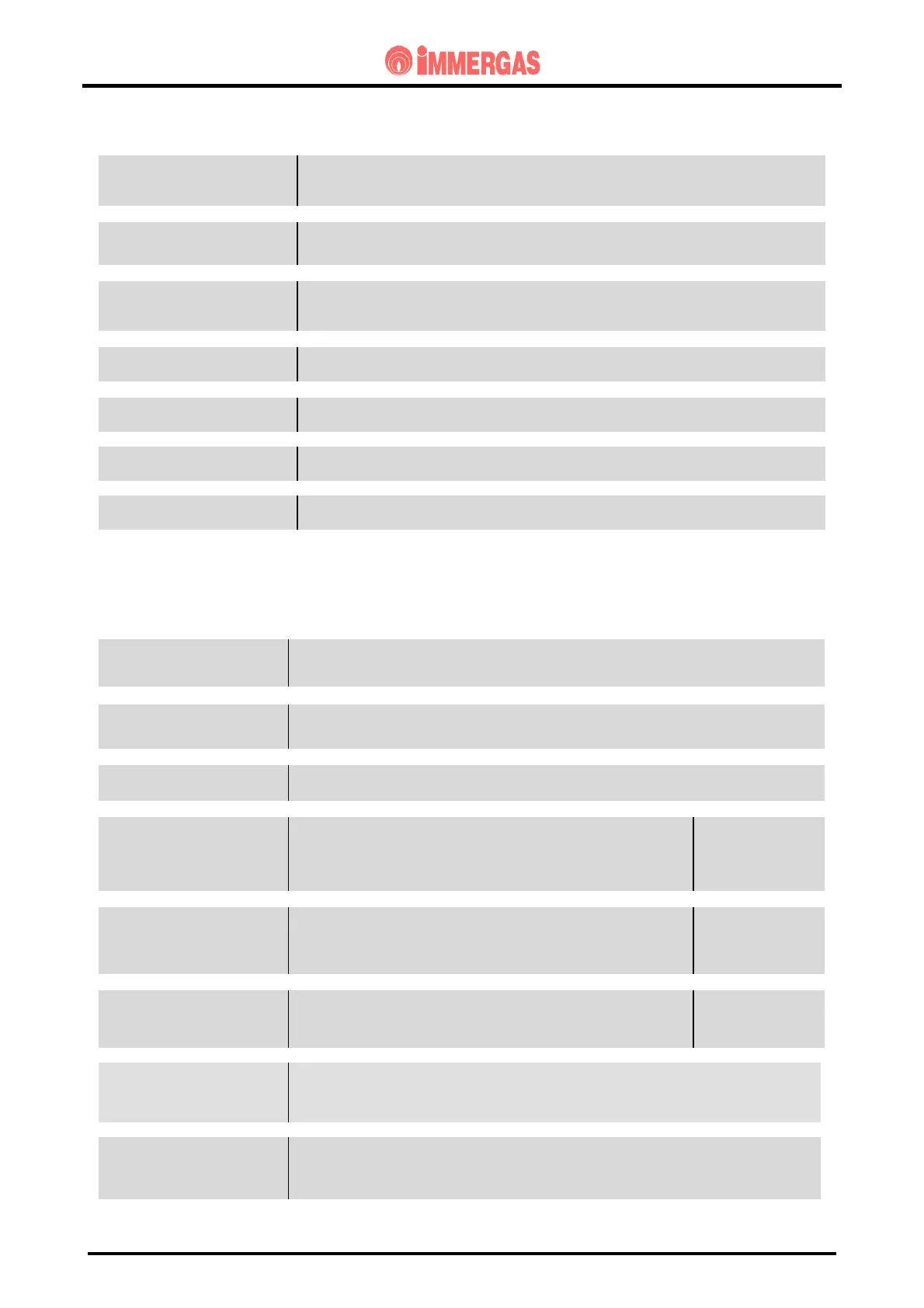

ADJUSTMENTS

Heating potentiometer

(RISC)

For setting the temperature of the water for heating 35 ºC to 80 ºC.

Hot water potenziom.

(SANIT)

For setting the temperature of the hot water 35 ºC to 55 ºC.

Gas switch (JP1)

Depending on its position (MET/LPG), it adapts the modulation parameters for the gas for

which the boiler is set (natural gas / LPG).

Gas switch G110

(M14)

For adapting the modulation parameters of the board to gas G110

(town gas).

Engaged using the jumper on gas switch JP1 (natural gas/LPG)

which must be shifted onto switch M14

off = natural gas or

LPG

on = G110

(with JP1 off)

Anti-leak hot water post-

circulation switch

(JP2)

For engaging or disengaging hot water post-circulation and hot-water

anti-leak (see safety devices and modulation board).

The boiler is supplied with these functions engaged as standard.

off = functions not

engaged

on = functions

engaged

Heating timer (JP3)

Every time the unit switches off after achieving set temperaturie

during heating phase, a delay of 180 s / 30 s is engaged until the

subsequent ignition for the same request.

off = 30 s

on (standard)=

180 s

Max heating power

trimmer

(POT. MAX RISC.)

For setting max power during heating phase and adapting this to system requirements (from

minimum to maximum regulated on gas valve).

This adjustment should be made about 2 minutes after ignition in heating phase.

Min heating power

trimmer

(POT. MIN RISC.)

For setting min modulated power during heating phase (from minimum to 2/3 maximum).

This adjustment should be made during first 20 s after ignition in heating phase.

Loading...

Loading...