24

3-1

INSTALLERUSERMAINTENANCE TECHNICIAN

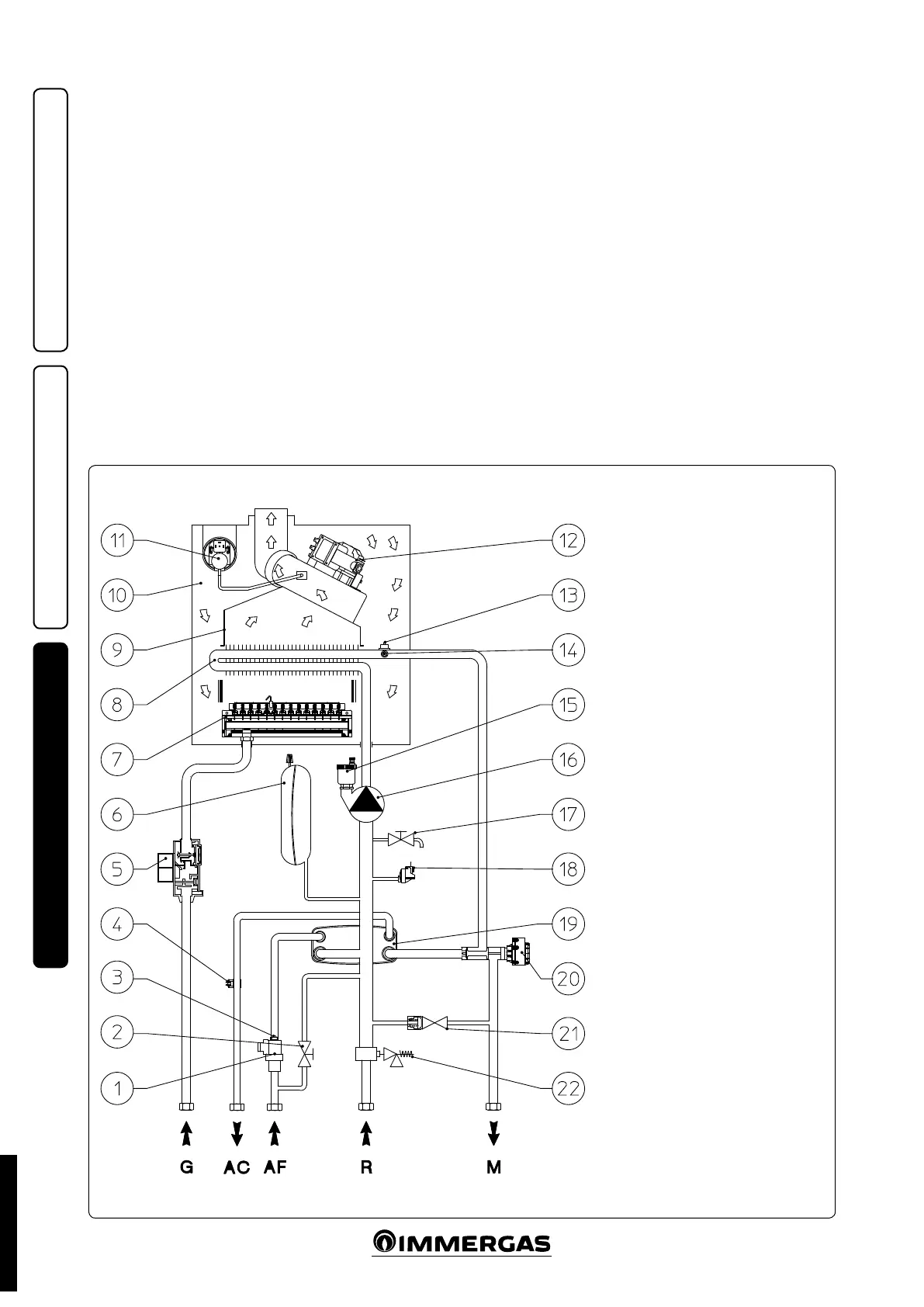

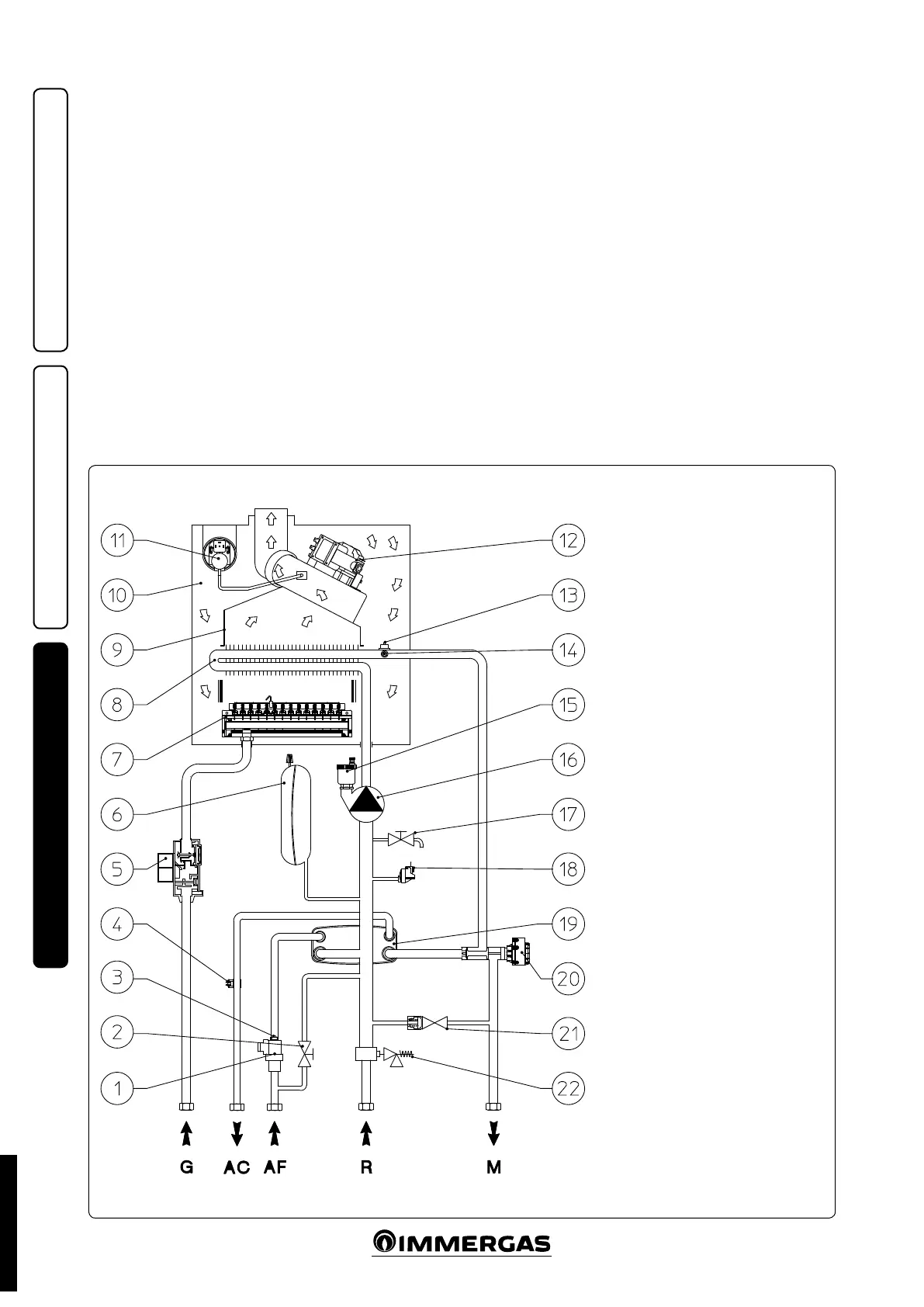

Key:

1 - Domestic hot water ow switch

2 - System lling valve

3 - Flow limiter

4 - Domestic hot water probe

5 - Gas valve

6 - System expansion vessel

7 - Burner

8 - Primary heat exchanger

9 - Fumes hood

10 - Sealed Chamber

11 - Flue pressure switch

12 - Fan

13 - Flow probe

14 - Safety thermostat

15 - Vent valve

16 - Boiler circulator pump

17 - System draining valve

18 - System pressure switch

19 - Plate heat exchanger

20 - ree-way valve (motorised)

21 - By-pass

22 - 3 bar safety valve

G - Gas supply

AC - Domestic hot water outlet

AF - Domestic cold water inlet

R - System return

M - System ow

3

BOILER STARTUP INI

TIAL CHECK

To commission the boiler:

- make sure that the type of gas used corresponds

to boiler settings;

- check connection to a 230V-50Hz power

mains, correct L-N polarity and the earthing

connection;

- make sure the central heating system is lled

with water and that the manometer indicates

a pressure of 1÷1.2 bar.

- make sure the air valve cap is open and that the

system is well deaerated;

- switch the boiler on and check correct ignition;

- make sure the gas maximum, intermediate

and minimum ow rate and pressure values

correspond to those given in the handbook

(Par. 3.18);

- make sure the gas supply failure safety device is

working, within its relative intervention time;

- check activation of the main switch located

upstream of the boiler;

- check that the intake and/or exhaust terminals

are not blocked;

- check activation of the “no air” safety pressure

switch;

- ensure activation of all adjustment devices;

3.1 HYDRAULIC DIAGRAM.

- seal the gas ow rate regulation devices (if set-

tings are modied);

- check the production of domestic hot water;

- check sealing eciency of water circuits;

- check ventilation and/or aeration of the instal-

lation room where required.

If even only a single safety check oers a negative

result, do not commission the system.

STD.002998/004

Loading...

Loading...