R

M

1

2

2

4

9

10

15

14

5

12

3

3

7

63

11

13

8

8

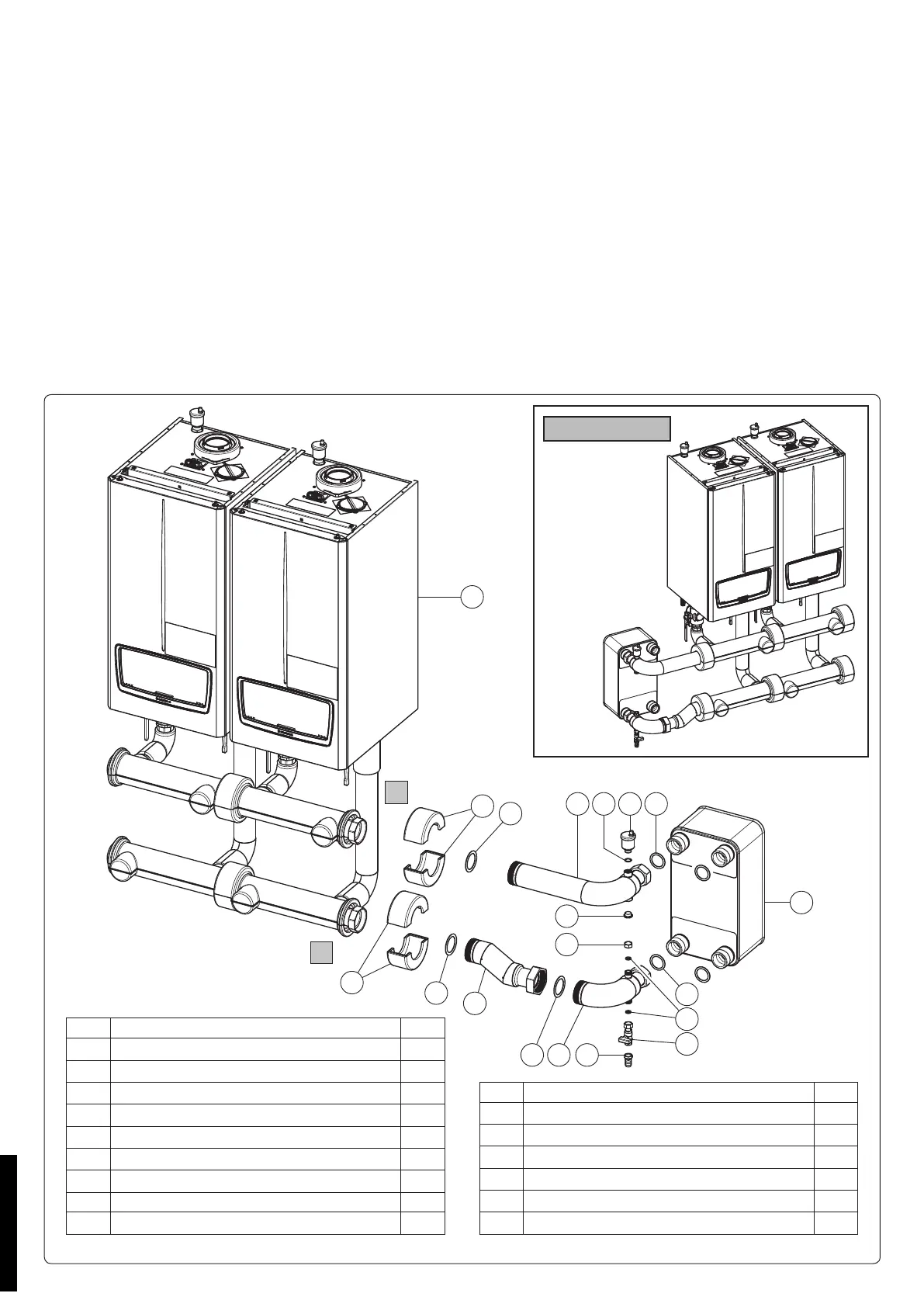

Ref. Kit components description Q.ty

1 18.5X11.5X2 AFM 34/2 2

2 56X44X2 AFM 37 gasket 4

3 75X55X2 mm gasket in Fasit So RG 3

4 Plate exchanger 1

5 O.R. 18X2 Nitrile 70 SH. 1

6 Roma type hose connection, female G1-2X15 1

7 Valve G 1-2 MF with tang 1

8 Insulation 4

9 Cap 1-2 F 23 mm Allen wrench 1

Mounting the plate exchanger for Victrix Pro 35-55-80 V2.

Assemble the automatic air vent valve (14) on the pipe (12) making sure to interpose the O-ring (5) and tighten the free connection with

the brass plug (10), making sure to interpose suitable sealing material such as oakum or similar.

Assemble the valve (7) and the hose connector (6) in sequence on the pipe (13), and on the free connection tighten the cap (9) making

sure to place the gaskets (1) in between.

Connect the pipe (11) to the pipe (13) in sequence on the return line (R) of the boiler (15), making sure to interpose the gaskets (3).

Connect the pipe (12) on the delivery line (M) of the boiler (15), making sure to interpose the gasket (3).

Position the insulation (8) on the delivery (M) and return (R) of the boiler (15).

Connect the pipes (12) and (13) to the plate heat exchanger (4), interposing the gaskets (2), as shown in Fig. 16.

Aer the 1st temperature test, check the tightness of all the pipes.

N.B.: e connections with caps 9 and 10 tted must be used for connections to the expansion vessel and for lling the boiler circuit (for

sizing the vessel, refer to the data table).

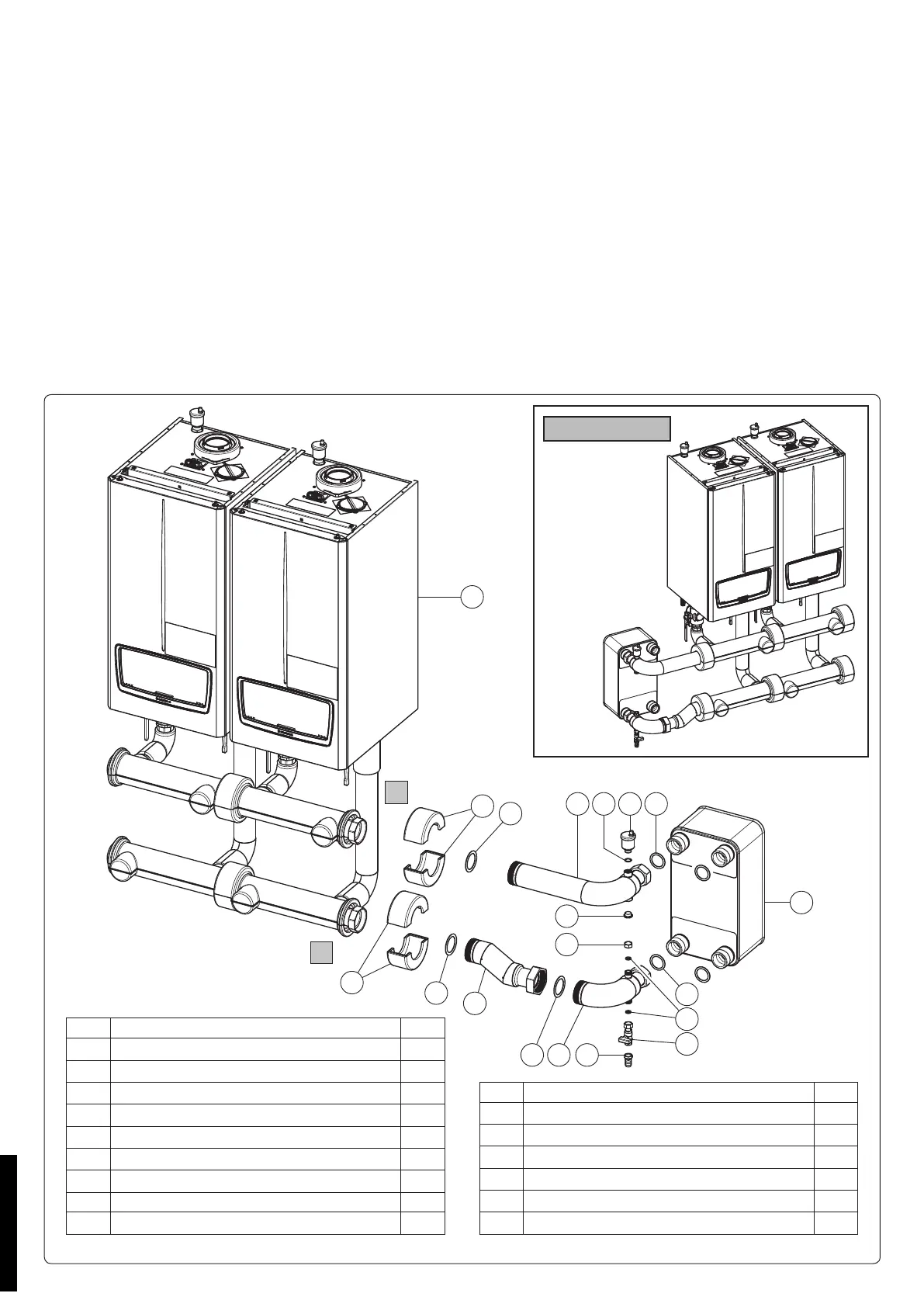

If assembling the kit with free outputs on the le side, perform the installation as shown in gure 17.

Attention: the VICTRIX PRO V2 boilers have an IPX5D electric insulation rating and can also be installed outdoors by means of the

relevant kits. However, if installed outdoors, the kit should be protected from the elements.

e boilers must be installed in the congurations and with their own original safety kits. e factory declines all liability whenever the

installer does not use the devices and approved original kits or uses them improperly.

LEFT OUTLET

16

Ref. Kit components description Q.ty

10 Kramer brass cap G 1-2 male 1

11 DN65 G2 1-2 MF return pipe 1

12 DN65 G2 1-2 M G2 F delivery pipe 1

13 DN65 G2 1-2 M G2 F return pipe 1

14 Automatic air vent valve 1-2 mini 1

15* Boiler -

17

* Components not present in the kit.

STD.010398/000

Loading...

Loading...