29

Servicing

Always disconnect the pruning shears from the power

cord when handling for other purposes than pruning and

ALWAYS WHEN SHARPENING, EDGING OR LUBRICATING.

Blade sharpening

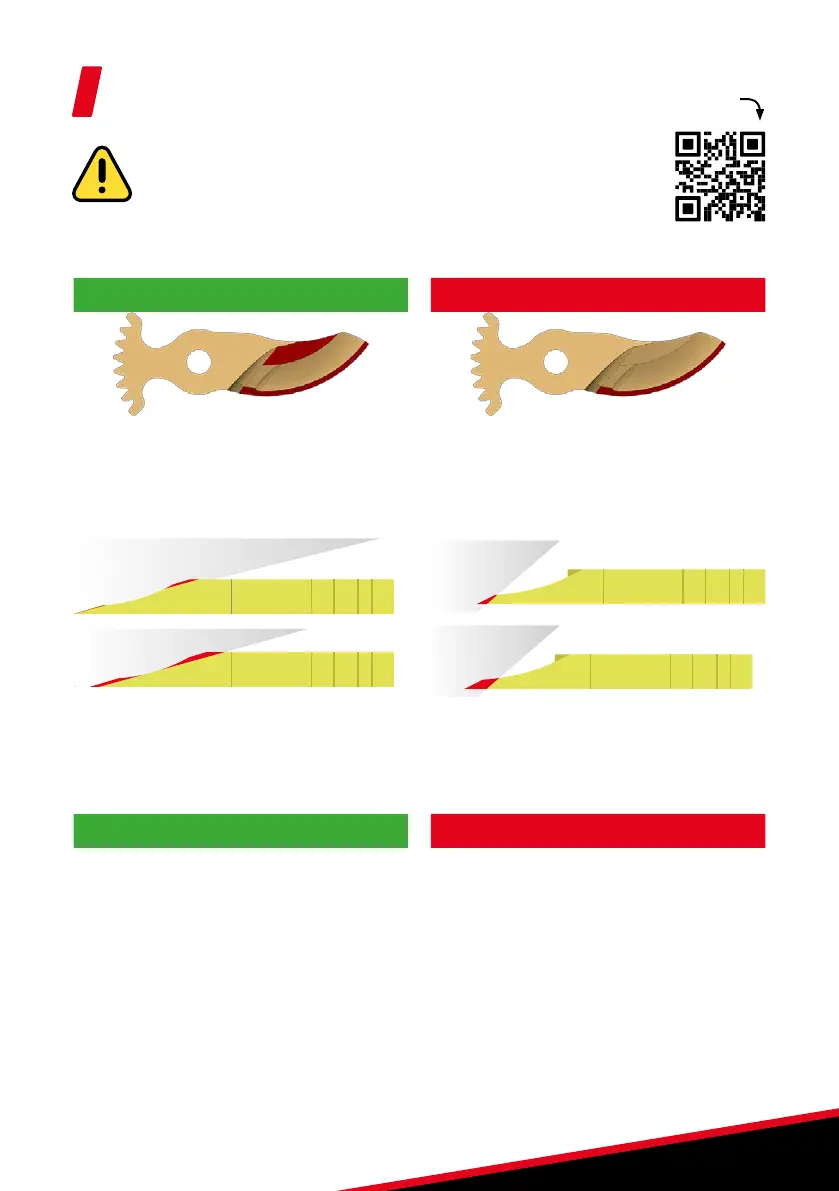

GOOD servicing BAD servicing

2 sharpenings / day + 1 edging / hour

Sharpening must be carried out flat on the

2 red slants to always keep the same angle of

penetration. (with a sharpening stone or optional

A48V3 electric sharpener).

If servicing is carried out by sharpening and/or

edging on the cutting edge only, the thin part of

the blade is eliminated. You lose the penetration

angle.

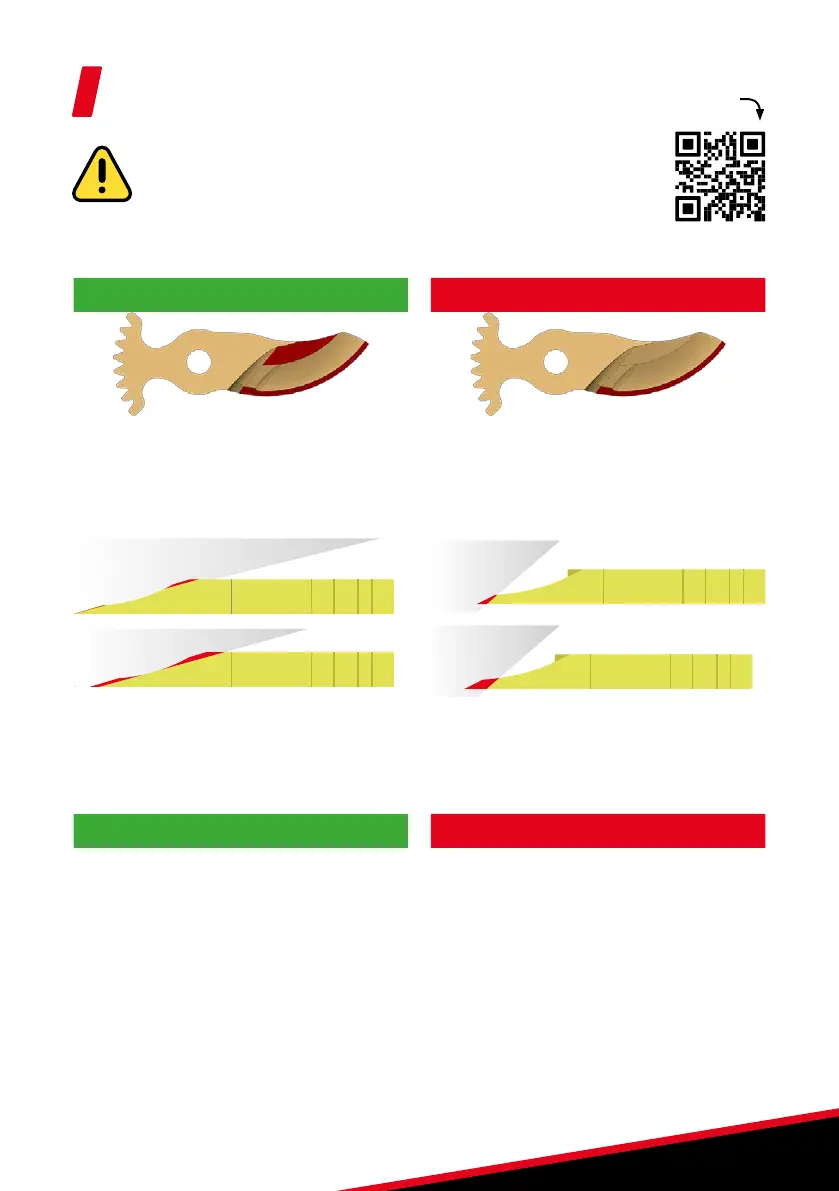

After 10 days

After 10 days

After 30 days

After 30 days

Edging consists in restoring the sharp side of the

blade and optimizes cut quality.

Carry out 4 passes with the carbide edging tool

(available from INFACO, ref. 950AF) on the bevel

+ 1 pass on the counter-bevel (back of the blade).

Important: Edging alone is not enough.

Good penetration Bad penetration

Result:

• Clean cut

• High cutting capacity

• Quick cutting

• Increased autonomy

• Reduced mechanical fatigue

• Longer blade service life

• Normal motor heating

• Higher yield

• Less strain on the user's wrist

Result:

• Significantly reduced cutting capacity

• Requires pressing the trigger several times

for medium cuts

• Much higher electricity consumption

Reduced autonomy

• Faster blade wear

• Causes the motor to overheat

• Time wasting

• The user's wrist is more strained (= MSD)

To optimize your blade service life to the maximum while maintaining perfect cut quality,

we advise you to use our A48V3 sharpener. You will also save considerable time in your

daily sharpening.

Sharpening

video

Loading...

Loading...