(B) Coolant Reservoir Tray

(E) Open Grid Work

Surface

(1) White (1) White

(F) BitSerts™ (2) White (1) White

(G) Coolant Feed Sponge (2) Yellow (2) Yellow

(H) Grinding Bit (2) 1" WB-9, 1/4" WB-8 (1) 3/4" WB-1

(I) Allen Wrench (2) Black (2) Black

(J) Splash Guard (1) White (1) White

To assemble your grinder:

Refer to the exploded view drawing. Place the Coolant Reservoir Tray on the white main Grinder Body by inserting the

locator pegs on the bottom of the reservoir into the corresponding holes in the grinder body. Place the work surface on

the coolant reservoir so that it sits on the inside lip of the reservoir. Insert the BitSert™.(Impulse™ owners refer to the

BitSert™ section on page 6 for more detailed information. ) Install the splash guard behind the BitSert™ by pushing

the posts into the grid holes of work surface. Note:The splash guard is reversible.

Installing the grinding bit:

Before mounting the grinding head and any time you change or remove heads, we recommend you apply a light

coating of Inland Motor Shaft Lubricant™ to the motor shaft (Stock #50022). Our Teflon based lubricant helps

prevent the bit from seizing on the shaft and seals out ground glass particles. In a pinch, you can use a bit of Vaseline.

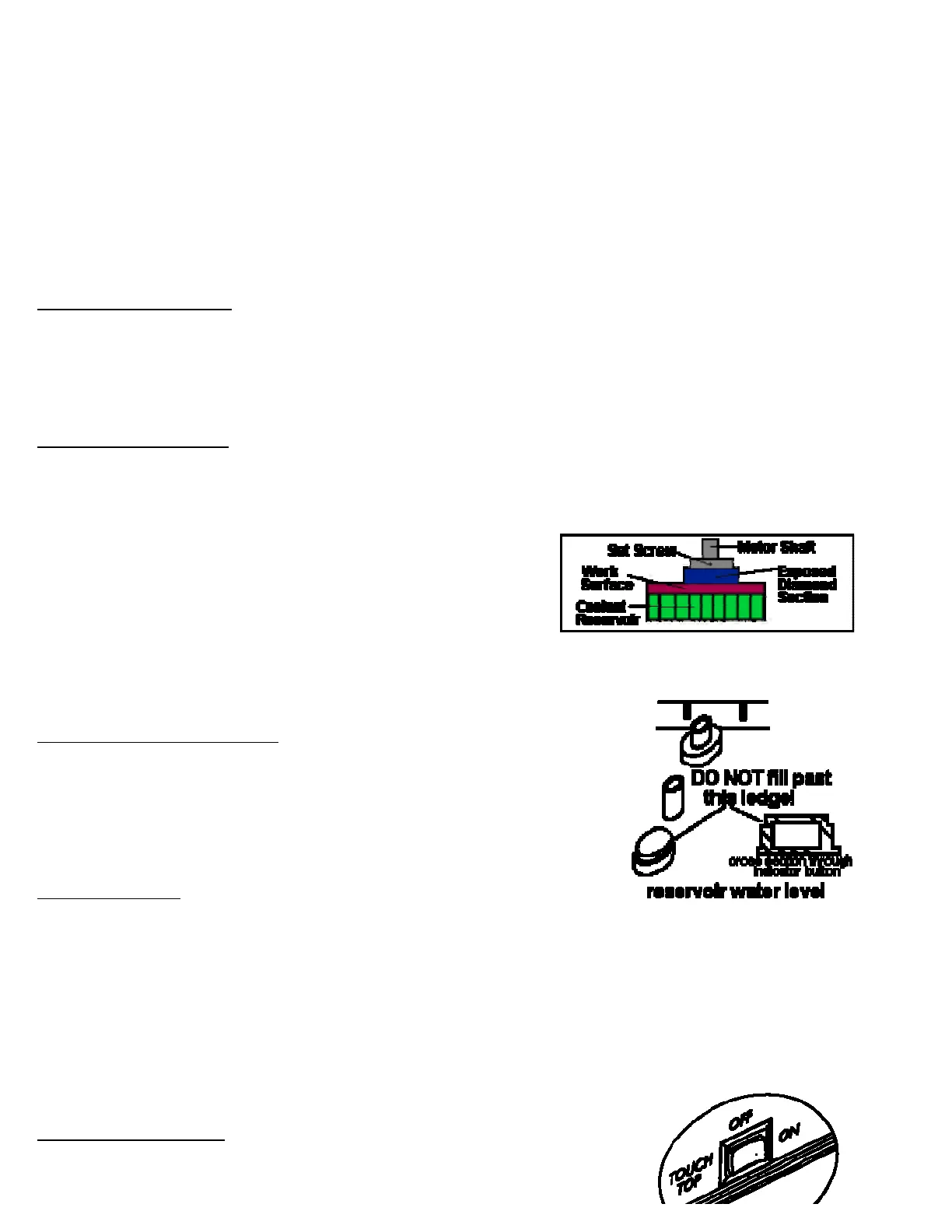

Select the 1" (Impulse™) or 3/4" (Aero™) grinding head. Use the allen

wrench to loosen the set screw by turning it counter clockwise. Slide the bit

onto the motor shaft. Turning it slightly will help it slide down. Position the

head so that about 1/8" of the silver diamond surface is above the work

surface. Make sure that the set screw sits over the flat side of the motor

shaft and secure the head in place by tightening the set screw. Important:

Always remember to sec ure to the flat side of the motor shaft. Mounting to the rounded side can scar the shaft

preventing bit removal.

Page 3

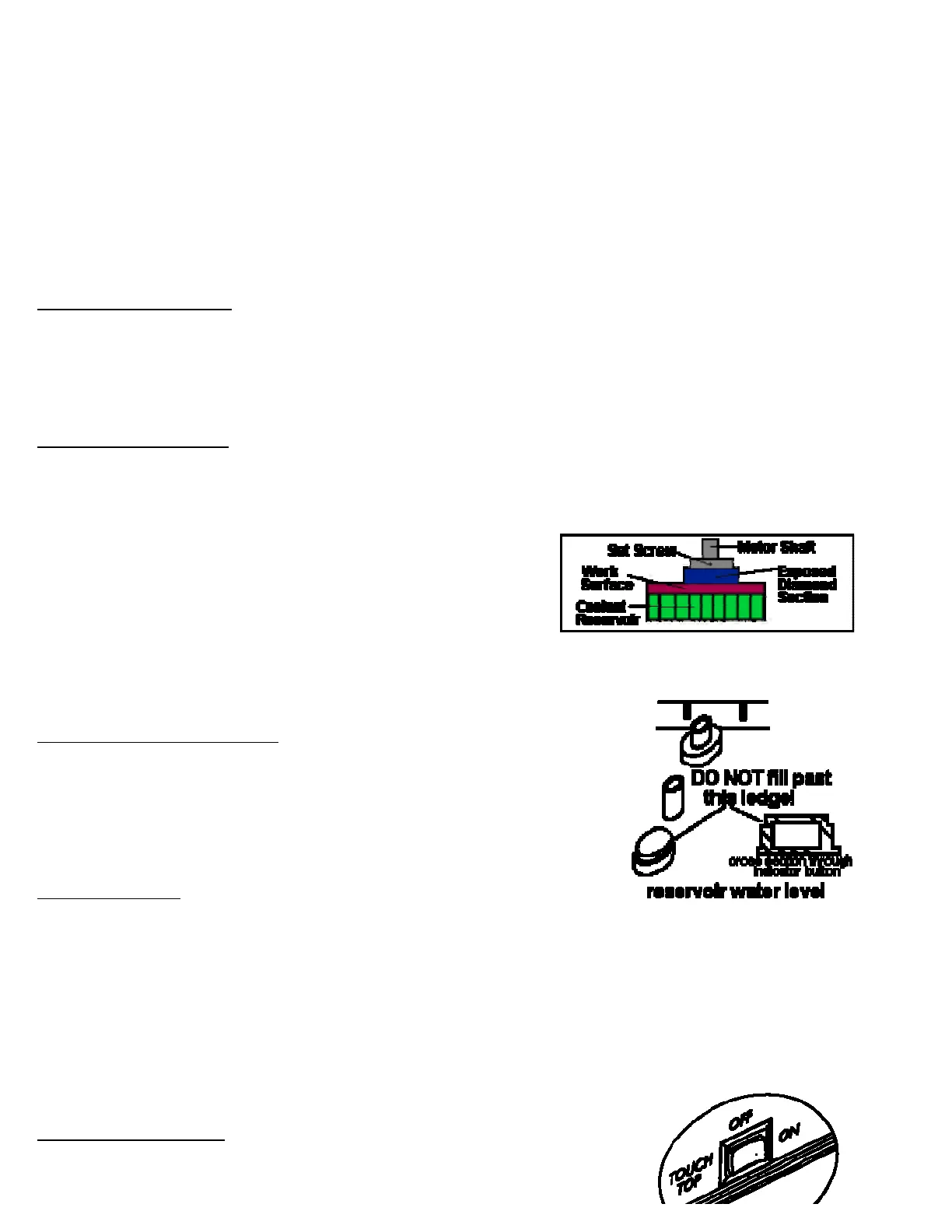

Filling the coolant reservoir tray:

Coolant helps keep glass dust from becoming airborne, increases grinding speed,

lubricates the diamond and increases the life of the head. Fill the reservoir by

removing the work surface and pouring water into the tray up to the fill level

indicator located in the tray center. You can also add a capful of Inland

DiamondCoolant™ to the water to further the life of the bit. Do Not Overfill the

reservoir. Causing coolant to flow out over the edges will damage the grinder.

Sponge placement:

The conventional way to get coolant onto the grinding head is to use a sponge held in by the BitSert™. Insert the

sponge into the slot of the BitSert™. The bottom of the sponge should contact the coolant in the reservoir, and the

upper portion should contact the diamond surface of the grinding head. You may need initially to wet the sponge. The

sponge should always be in contact with the head. If a white paste develops on the head while grinding, either the

sponge is not properly positioned on the bit or the coolant level is low. Periodically remove the sponge and rinse it out

to remove grinding residue.

An alternative to the sponge is the patented InvisibleSponge™ system explained in the BitSert™ section on page 4. It

is a standard feature on the Impulse™ and available as an accessory (Stock #40035) for the Aero™.

Page 4

The TouchTop™ Feature:

Your grinder has a three-way switch on the right side of your grinder. The grinder can

be off, on or TouchTop™. When set for TouchTop™, the grinder turns on when you

http://www.inlandcraft.com/Uguid... 7/13/2013

Loading...

Loading...