put the glass and your hands onto the work surface to grind and turns off when you

remove your hands. Using the TouchTop™ switch selection will extend motor life. You

can adjust the sensitivity of the work surface to the feel you like best. When you adjust

the sensitivity of the TouchTop, put a weight of about 1 lb. on top of the work surface. The weight will compensate for

the load of the coolant that will be in the reservoir when it is being used. Under the reservoir is a sensitivity set screw:

turning the screw tighter, or clockwise, decreases the sensitivity. By loosening the screw, or turning it counter-clock

wise, you increase the sensitivity. Adjust the sensitivity of the work surface to your preference now.

Grinding:

It is advisable first to test grind a scrap of glass to get a feel for grinding. Make sure the sponge is touching the

grinding head. Turn the machine to either TouchTop™ or 'On'. Begin by pushing the glass into the diamond bit using

light pressure at first. As you grind, move the glass back and forth across the head. Slowly increase the pressure until

you feel comfortable with the grinding speed and your control. If you need to grind out a deep cut, use intermittent

pressure. This allows coolant to clean the head making it more effective.

If you notice a white powder or paste while grinding, immediately stop and check the position of the sponge and the

coolant level. Grinding without coolant on the head greatly reduces its life. When you notice that the head doesn't

seem to grind as well and more pressure is needed to grind, the diamond is wearing and you need to expose a new

section of diamond. Loosen the set screw and move the grinding head up on the shaft until you have exposed a new

1/8" section of diamond. Secure in place and reposition the sponge if needed. You have up to five 1/8" sections of

diamond on a standard grinding bit to use before you need to consider replacing the entire bit

Page 5

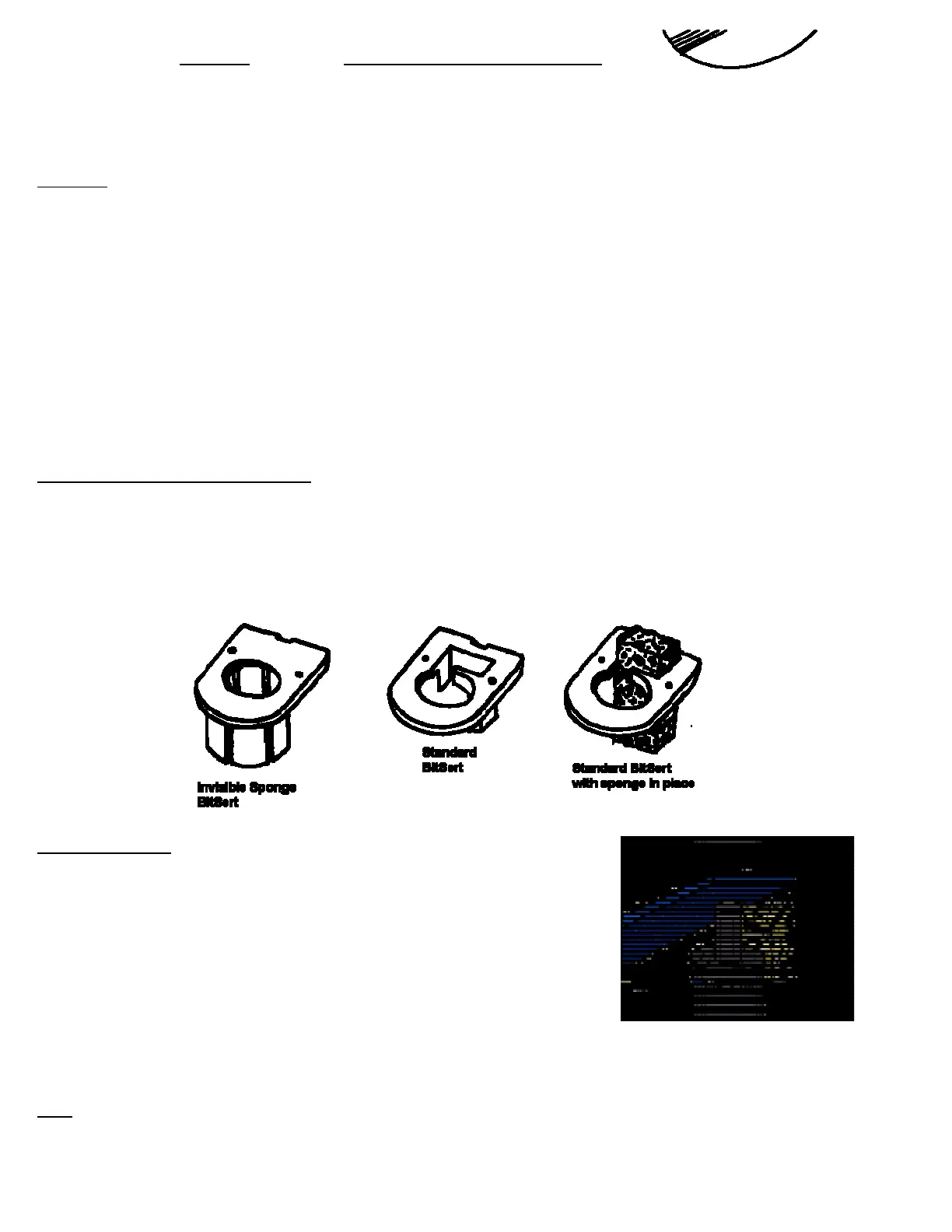

BitSerts™ and the InvisibleSponge™

Impulse™ grinders are equipped the InvisibleSponge™ BitSert™ for 1" bits. The InvisibleSponge™ BitSert™

eliminates the need for a sponge most of the time. It works by automatically pumping coolant to the bit while you are

grinding. You will find it more effective to use a standard BitSert™ to use up the lowest section of diamond on the bit.

To use: Remove the standard BitSert™ and sponge and install the InvisibleSponge™ BitSert™ in the work surface.

Adjust the position of the bit if necessary. Turn on an allow water to reach bit surface before grinding.

How to drill a hole:

The Impulse™ includes a 1/4" WB-8bit for intricate grinding and drilling holes.

Place the WB-8bit onto the shaft so it sits on top of the WB-1. Secure to the flat of

the shaft. Begin drilling the hole by holding the glass finished side down to the upper

edge of the bit at about a 45

o

angle. Refer to the diagram on page 7. You will need

to hold a coolant soaked sponge against the bit as you drill the hole. As the bit

begins to grind out the hole, slowly move the glass to a horizontal position. Continue

to press the glass down onto the bit making sure that the sponge is supplying

coolant to the bit. Reload the sponge with coolant as needed. Ease up on the

pressure just before the bit comes through the back of the glass to reduce chipping.

It is advisable to practice on a scrap of glass before you begin drilling on your final project.

Page 6

Bits:

Diamond grinding heads, or bits, have actual diamond crystals. Our 1" and 3/4" standard bits have a 5/8" vertical

section of usable diamond. Since most stained glass is 1/8" thick, by adjusting the bit up and down on the shaft you

http://www.inlandcraft.com/Uguid... 7/13/2013

Loading...

Loading...