EMC

MD380 User Manual

- 258 -

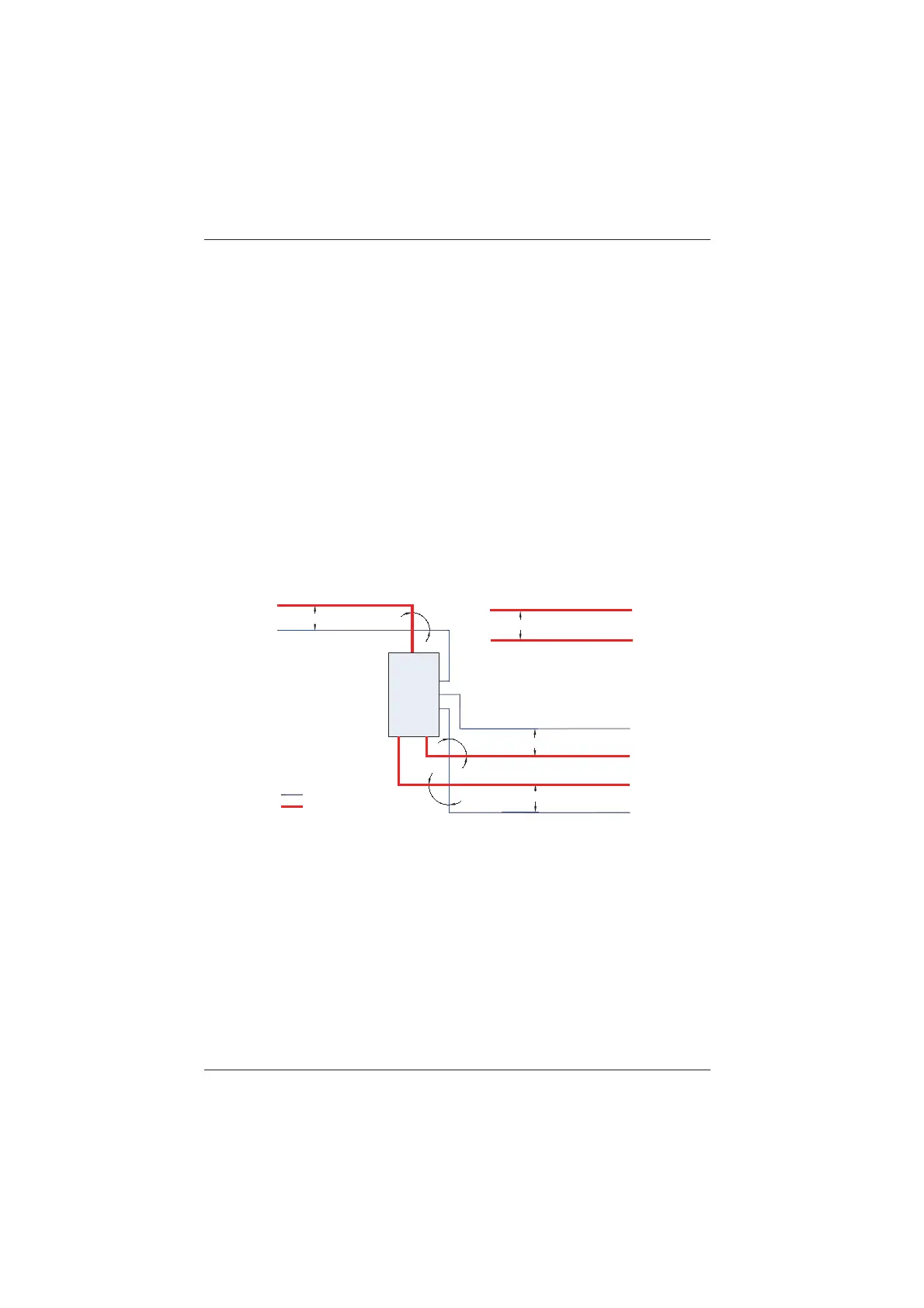

7.4.2 Cabling Requirements

1) The motor cables must be laid far away from other cables. The motor cables of several

AC drives can be laid side by side.

2) It is recommended that the motor cables, power input cables and control cables be laid

in different ducts. To avoid electromagnetic interference caused by rapid change of the

output voltage of the AC drive, the motor cables and other cables must not be laid side

by side for a long distance.

3) If the control cable must run across the power cable, make sure they are arranged at

an angle of close to 90e

2WKHUFDEOHVPXVWQRWUXQDFURVVWKH$&GULYH

4) The power input and output cables of the AC drive and weak-current signal cables

(such as control cable) should be laid vertically (if possible) rather than in parallel.

5) The cable ducts must be in good connection and well grounded. Aluminium ducts can

be used to improve electric potential.

6) The filter, AC drive and motor should be connected to the system (machinery or

appliance) properly, with spraying protection at the installation part and conductive

metal in full contact.

Figure 7-2 Cabling diagram

MD380

AC drive

Min. 200 mm

Min. 300mm

Power cable

Motor cable

Min. 500 mm

Min. 500 mm

Braking resistor cable

Motor cable

Power cable

90°

90°

90°

Control cable

Control cable

Power cable

Control cable

Control cable

efesotomasyon.com

Loading...

Loading...