Pa

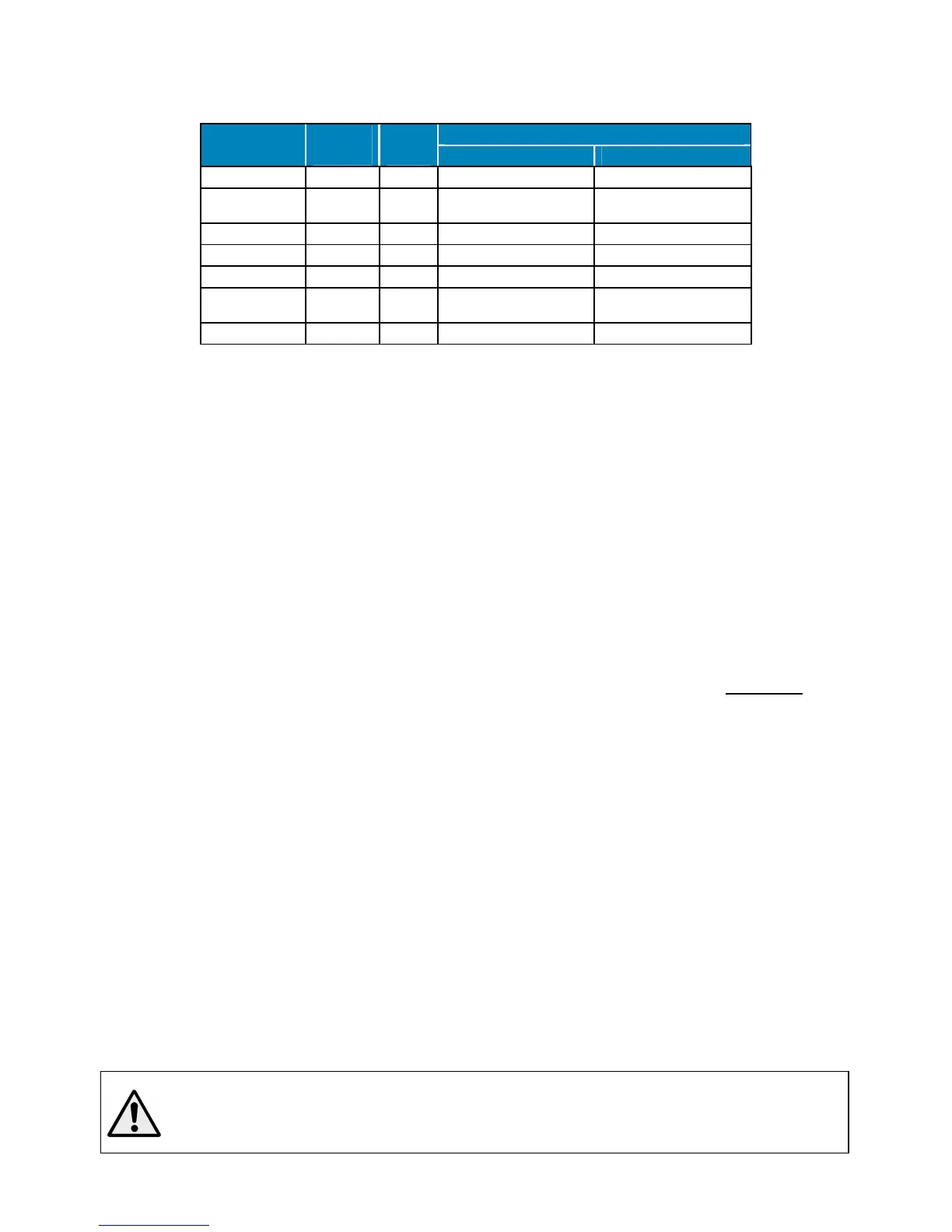

Recommended duct dimensions (mm)

Semi-flexible Rigid (PVC or steel)

CV 0 series

375 120

Ø 200 Ø 150

CV 1 series

575 120

Ø 250

< 20 m: Ø 150

>20 m: Ø 200

CV 2 series

950 120

Ø 315 Ø 200

CV 3 series

1250 120

Ø 315 Ø 250

CR 0 series

375 120

Ø 200 Ø 150

CR 1 series

575 120

Ø 250

< 20 m: Ø 150

>20 m: Ø 200

CR 2 series

1150 120

Ø 315 Ø 200

§ It is recommended a minimum length duct, avoiding placing unnecessary turns. Failing a detailed

calculation, it can be supposed that a 90º turn, with no internal radio, is equivalent to 5 m length.

§ If air intake is not ducted, an air intake adequate to the room should be planned.

§ It is not recommended the use of flexible ducts due to pressure loss, being only acceptable in case

of straight and very short stretches. If so, an aluminium semi-flexible duct as indicated diameters is

recommended.

22. START-UP

Before starting the unit,plese check that the unit is properly fixed on its supports and the electrical

connections are properly installed. If you have worked on the unit, take care not to forget tools or any

objects inside, that there is no gas leak and that assembly-connection are properly done.

Before starting up or after a stand-by periods, activating the crankage heater (when included) at

twelve hours in advance is recommended. Otherwise, the compressor must be warmed up in a

different way to ensure the refrigerant-oil separation. This operation is important, specially when

starting-ups in low ambiance temperatures.

Connect the electrical supply and switch on the unit with room door closed. The display will show the

room temperature and after the time as specified for Ods parameter the compressor will start.

Set the cold room temperature set point and wait until the cold room temperature reaches the set

point. The high temperature alarm will not be activated until the time of dAO parameter is elapsed.

Once the target temperature is reached, initialise the record of maximum and minimum temperature as

indicated in thism anual. You may check that auxiliary devices work properly:

§ Room light.- turn on and off the room light.

§ Door switch.- check that the compressor and fans stop when opening the door.

Force a manual defrost cycle to check this operation mode. make sure that the evaporation coil gets

clean and that the unit stays within the normal operating parameters without activating any safety

device.

Depending on the application you may need to modify defrost parameters, such as time

period between two consecutive defrost cycles, defrost cycle duration or termination

temperature. To do so, pay attention to the defrost cycles during normal operation.

Loading...

Loading...