8 ID-299 Iss 3 08/07/987ID-299 Iss 3 08/07/98

Option Wiring

ALARM only Output Relay 2 is fitted.

The alarm is normally closed, going open circuit in the event of a fault.

This output may be fitted to provide additional protection of the kiln. It principally guards against failure of the main

contactor. It should not be seen as a direct replacement for an over temperature policeman.

EVENT only Output Relay 2 is fitted.

May be configured as a user programmable Event (e.g.. To operate a damper)

(See also notes on programming under ‘Auxiliary Relay’)

This will normally be used to either drive a motorised valve for damper control, or an external signalling device to initiate

other parts of a control system. To drive a motorised valve an additional external (Customer Supplied) relay must be used.

This should have N.O. and N.C. contacts to drive the ‘Open’ and ‘Close’ feeds on the valve.

ALARM + EVENT Output Relays 2 & 3 are fitted.

O/P 2 is the Event and O/P 3 is the Alarm.

GAS O/P 4 is fitted (This may be in addition to any of the above.)

This output may be fitted to provide ignition and shutdown of a gas fired kiln. The Burner should have an ignition control input

(which is fed from the ‘Gas’ relay), and a High/Low fire control input (which is fed from the main control output.)

ZONE All O/P Relays are fitted.

Selection of functions is via link blocks. (See previous page)

For a three zone control only one output is available for alarm or event. The provision of both is thus not possible.

It is

recommended that an entirely separate over temperature alarm be fitted in this instance. This should be considered standard

practice for an installation of the likely value of a three zone kiln.

2 Zone control may be implemented simply by not using the third zone. The unwanted zone must have its thermocouple input linked

between +VE to -VE to prevent the controller causing an open circuit thermocouple. error message.

It is vital that the correct relationship between thermocouple and contactor is maintained, such that the thermocouple is

measuring the temperature of the heater it is controlling. Failure to observe this may cause damage to the kiln.

The connections to a three zone kiln will be influenced by the design of the kiln, and no definitive connection information can be

given. The following points may be of assistance.

1/ Where uniformity of temperature is the principal objective, then the main control output (Terminal 1) should drive the

slowest zone in the kiln. Since the controller can only slow down the natural rate of rise of the kiln it is thus in the best

position to keep the “slaves” in step with the “master”.

2/ Whilst the slaves are identical in function the display implies that zone 2 is above zone 3. Providing this orientation in

practice will be less confusing to the user.

3/ Ensure that the thermocouples are positioned as far away from direct element heat as possible, and in the centre, or

slightly below the centre of each heating zone.

Electrical Connections

Please Note

The Industrial Pyrometer Co do

not supply specific wiring

diagrams for individual kilns since

the accuracy of such information

cannot be confirmed.

Incoming Supply

This should be connected to a 230V supply via a fuse of 1A rating. An Earth connection is essential.

Thermocouple Inputs

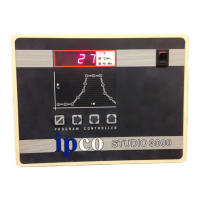

Ensure that the Studio 3000 Controller and the Thermocouple are of the same type, otherwise accurate control of temperature

in the Kiln will not be possible. The letter prefix on the Serial Number Label (N, K, R or S) will indicate the thermocouple

type that has been programmed into your Controller.

All input wiring should use screened cable of the appropriate compensating type, with correct polarity maintained

throughout.

See also ‘At switch On’ for explanation of the initial identification message.

‘Parameter Setting’ to change the instrument thermocouple type.

Control Outputs

NB ALL outputs are low current and MUST drive remote relays or contactors which in turn drive the load.

The ‘C’ (Common) terminal is internally connected to 230V via the ON/OFF switch.

To isolate the relays from this 230V feed remove link LK1 The maximum switching voltage is still 230V.

MAIN OUTPUT (Relay 1) This output feeds the kiln contactor coil

OPTIONS (Relays 2 to 4) See following page for Option output information.

EMC

To comply with current EMC regulations, the system, of which this controller is a part, must conform to the relevant standards for

electrical emissions. It is the responsibility of the end supplier to ensure this is achieved.

The following is our recommendation only.

The control contactor(s) should be fitted with suppressers at all terminals

which are switching the load.

(This means that they cannot be relied upon for safety isolation)

The coil should be fitted with a suppressers.

S = Suppression Device

e.g. Farnell 218-913

R.S. 210-364,210-370

Where slave relays are used these should also be suppressed.

Do not fit suppressers to over temperature controllers, or safety isolation contactors.

Loading...

Loading...